Our Wave Soldering Pallet AGV is for moving wave soldering pallet,ESD SMT magazine rack,PCB and PCB fixture.Our SMT AGV robot offers automation for an electronic manufacturer. Specifically for DIP insertion lines in SMT (Surface Mount Technology) factories. This innovative solution helps return wave soldering pallets efficiently, increasing productivity while reducing labor costs. It is also a great helper for SMT material handling and SMT warehouse and logistic.

With self-guided driving and advanced lithium battery technology, our AGV offers cost-saving and efficient transport solutions for SMT production lines and PCB assembly. Explore our customizable Wave Soldering Pallet AGV for your smart factory needs.

Key Features of the Wave Soldering Pallet AGV ETE-AGV60

- High Load Capacity: Supports up to 60 kg.

- Flexible Charging Options: Choose between manual charging or battery replacement for convenience.

- Intelligent Alerts: The AGV automatically notifies operators when the battery is low.

- Comprehensive Warranty: Includes a one-year warranty for the unit and a two-year warranty for the battery.

- Free Accessory Package: Each unit ships with a complimentary set of accessories.

- Long Battery Life: Features a specialized lithium battery that provides up to 15 hours of continuous operation, with customizable runtime options available.

- Auto-charging pile: AGV can be optionally equipped with an auto-charging pile.

- AGV Voice Notice: Our AGV is smart to give a voice notice.

Two Model Options Available

1. ETE-AGV60-A

- Advanced Sensors: Equipped with an ultrasonic obstacle sensor.

- Compact Turning Radius: A turning radius of 0.8 meters for maneuverability.

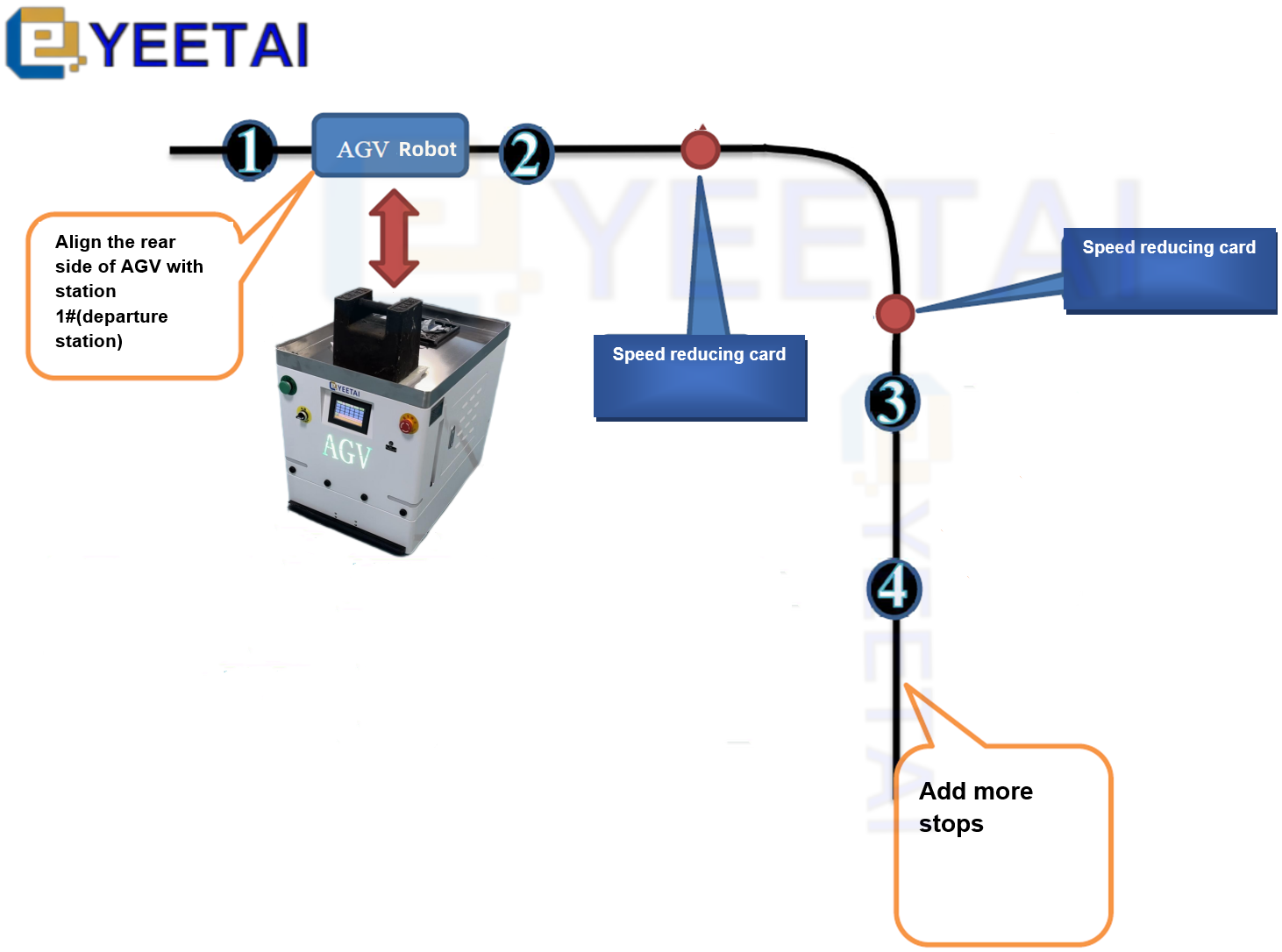

- Programmable Routes: Set your own automatic running routes.

- Efficient Drive System: Utilizes a brushless motor with differential drive technology.

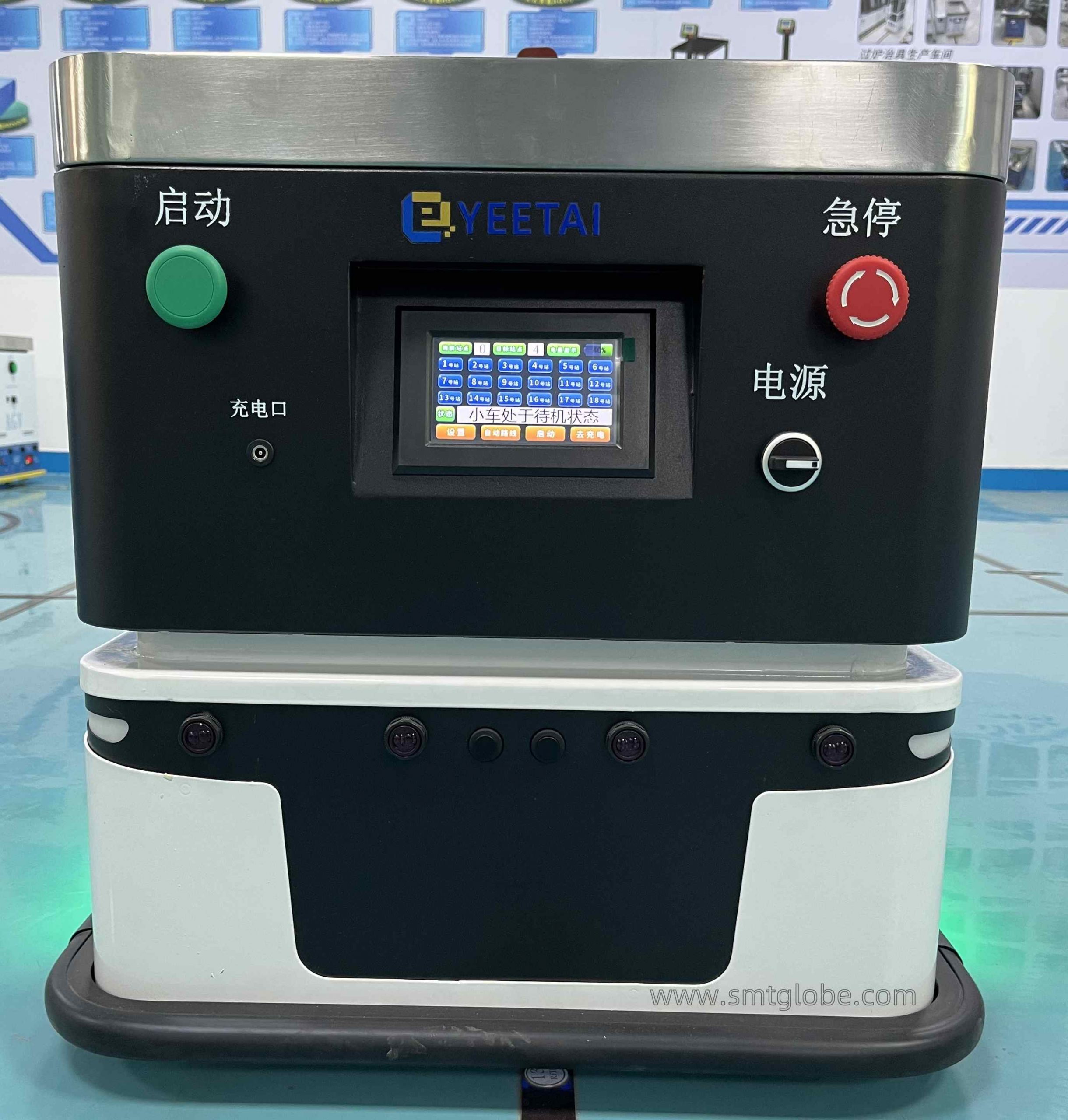

- User-Friendly Interface: Comes with a 4.5-inch high-definition touch screen.

- Versatile Operation Modes: Supports single line, loop line, remote control, and custom branch line routes.

- Remote Control Capabilities: 15-key remote control for precise navigation, including forward, backward, and side movements.

2. ETE-AGV60-B

- Basic Functionality: Primarily for single line operation.

- Wider Turning Radius: A turning radius of 1 meter.

- Custom Remote Options: Optional custom remote control available.

- Reliable Drive: Features a reduction motor with differential drive.

- Safety Measures: Equipped with an infrared obstacle sensor.

- Multi-Point Stop Capability: Stops at multiple designated points.

- Delayed Start Function: Allows for delayed starts at stations for better workflow control.

Specification

| Model | ETE-AGV60-A | ETE-AGV60-B |

| Navigation method | Navigation strip; can drive towards inter-direction | Navigation strip; can drive towards inter-direction |

| Loading capacity | 60KG | 60KG |

| Driving mode | single line,circle route,remote control,branch route(customizable) | single line |

| Max. speed | 20-40m/minute(adjustable) | 20-40m/minute(adjustable) |

| Min. Turning radius | 0.8m | 1m |

| Stop accuracy | 2CM | 2CM |

| Battery Type | lithium battery 24V20AH | lithium battery 24V20AH |

| Battery life | >15hours(customizable) | >15hours(customizable) |

| Standby time | 200 hours | 200 hours |

| Charging time | 4 hours | 4 hours |

| AGV dimension(MM) | L550X W450X H 550 | L550X W450X H 550 |

| Plate dimension(MM) | L520X H430X H 50 | L520X W430XH50 |

| AGV weight | 35KG | 30KG |

| Wireless remote control | 15-key stop selection+driving with a remote control | optional |

| Running indicator | LED lights both at the Front and rear; running indicator light + flashing red light when there is an obstacle | |

| Drive | Brushless Motor Differential Ratio | Geared Motor Differential Ratio |

| Obstacle detection method | Ultrasonic radar + emergency stop switch | Infrared sensor + emergency stop switch |

| Touch anti-collision switch bar | 1 at the front and 1 at the back | 1 at the front and 1 ant the back |

| LCD display | 4.3-inch high-definition touch screen (wireless communication is optional) | Without |

| Automatic Route Planning | Automatic Route Planning mode available | Automatic Route Planning mode available |

| Start | Manual start + timing start + remote control start; | Manual start + delayed start; wireless serial communication can be added to support secondary development |

| Site selection | 20 sites choose RFID card identification | Multi-site stop |

| Charging method | DC charging/ battery charging | |

| Remaining power indicator | Smart Alarming | |

| Spare part | 20m navigation strips, 20 RFID site cards, 6 deceleration cards, 4 obstacle avoidance cards, 4pcs 5A chargers | |

| Warranty | 1 year | |

Contact Us

If you have specific needs or require customized solutions, please reach out to us. We offer a variety of AGV robot models tailored to meet the diverse demands of SMT factories.

AGV Robot for SMT factory | ETE-AGV-760A

SMT loader AGV for ESD magazine rack | ETE-AGV-LM01

Conclusion

YEETAI’s ETE-AGV60 Wave Soldering Pallet AGV can revolutionize your SMT production by enhancing efficiency, increasing safety, and reducing operational costs. Discover how our innovative solutions can support your manufacturing needs today!