To ensure the optimal performance and longevity of V-Cut PCB depaneling machines, proper maintenance is crucial. Here’s a comprehensive guide on maintenance procedures and important considerations.

1. Power Off and Clean After Each Use

At the end of every workday, operators should turn off the machine and clear away any debris. This step maintains cleanliness, preventing waste from affecting the equipment’s performance. A tidy workspace also ensures a smooth start for the next day’s operations.

2. Care for the Cutting Blades

The cutting blades are vital components of the depaneling machine. Operators must handle them with care to avoid damage. Check the blades regularly for wear; if they show signs of damage or reduced performance, replace them immediately. Additionally, apply a bit of machine oil to the blades periodically to enhance their longevity and maintain cutting efficiency.

3. Protect Blades During Extended Downtime

If the machine will not be used for an extended period, it’s advisable to remove the cutting blades and apply a protective layer of machine oil. This precaution prevents rust and damage, ensuring that the blades remain in good condition for future use. Before using the machine again, wipe off excess oil and check for cleanliness.

4. Regularly Inspect Fasteners

Regular checks of all screws and fasteners are essential. Loose screws can lead to operational instability and safety hazards. If any screws are found to be loose, tighten them using appropriate tools to ensure the machine operates safely and effectively.

Conclusion

Implementing these maintenance procedures will help guarantee the long-term stability of V-Cut PCB depaneling machines. Consistent cleaning, protective measures, and regular inspections can significantly extend the equipment’s life and ensure optimal performance when you need it the most. Following these guidelines will lead to efficient operations and reduced downtime, contributing to overall productivity in your manufacturing process.

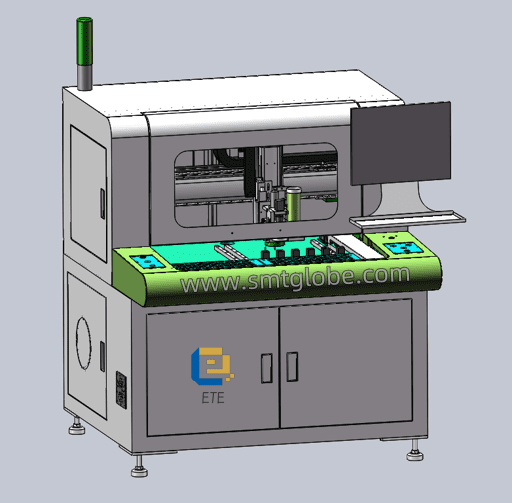

We are experienced at PCB depaneling. Know more PCB depaneling solutions in our website: www.smtglobe.com