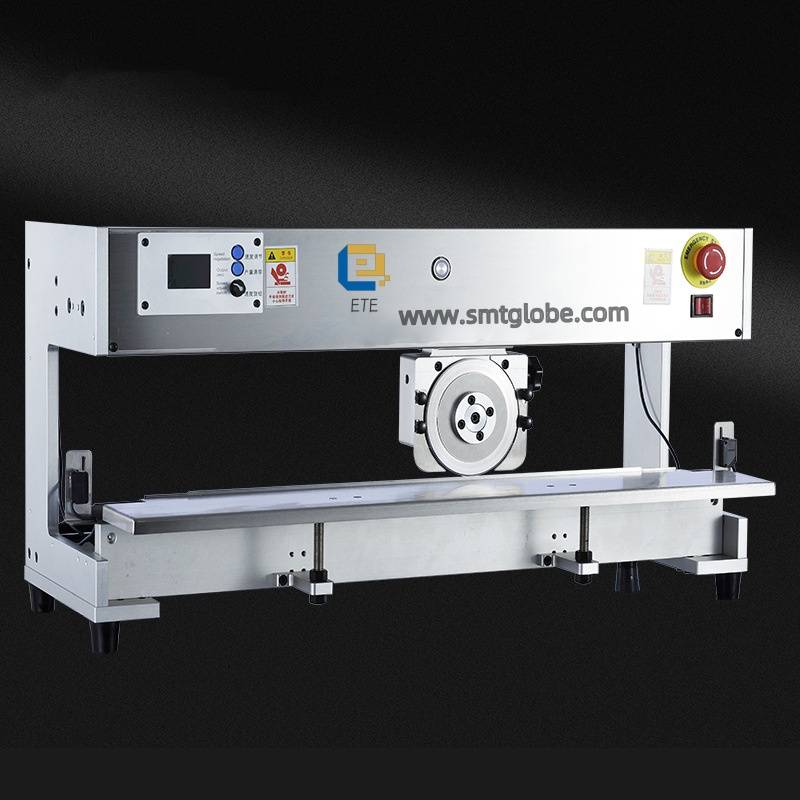

V-cut PCB depaneling machine ETE-508-600 for 600mm PCB Circuit Boards.

Enhance your PCB manufacturing process with the V-cut PCB depaneling machine. It is a high-precision depaneling equipment for 600mm circuit boards. Our machine has high-speed steel blade and V-cut compatibility. Thus it ensures clean and accurate cuts for PCBs up to 600mm in length. Improve your production efficiency and product quality with our advanced ETE-508-600 depaneling machine. Contact us to learn more!

Features of V-cut PCB depaneling machine

- Adjustable Cutting Speed

- Two speed settings available: 500 mm/s (high speed) and 300 mm/s (low speed).

- Faster blade speeds enhance product quality by producing clean and burr-free cuts.

- Customizable Blade Travel Distance

- Blade travel distance adjustable from 0 to 500 mm.

- Customizable blade length options are available.

- Fine Blade Height Adjustment

- Blade height can be finely adjusted from 0 to 2 mm.

- Accommodates various PCB thicknesses and resolves V-CUT cut depth issues.

- Adjustable Operating Table Height

- Operating table height can be adjusted from 0 to 50 mm for optimal working conditions.

- Versatile “V” Slot Guide

- Vertically adjustable “V” slot guide for accommodating different substrate thicknesses.

- Facilitates faster and more secure adjustments, increasing application range.

- Cost-Effective Blade Maintenance

- Cutting knives can be re-sharpened and reused multiple times, significantly reducing operational costs.

- Minimal Cutting Stroke for Safety

- Cutting stroke is less than 1-2 mm, ensuring safe operation without compromising performance.

- Durable Blade Material

- Blade manufactured from SKD11 high-speed steel, known for its wear resistance and durability.

V-cut PCB depaneling machine Specifications:

Model: ETE-508-600

Main machine size: 883mmx363mmx410mm

Depaneling thickness: 0.8-3.0mm

Maximum depaneling length: 600mm

Maximum depaneling width: unlimited

Feed speed: 300-500mm/second

Blade material: SKD61 high-speed steel

Operating temperature: 10-35℃

Storage temperature: -20-50℃

Power supply: 220V/110V, 50HZ/60HZ, 60W

Machine weight: 32KG

Safety Measures:

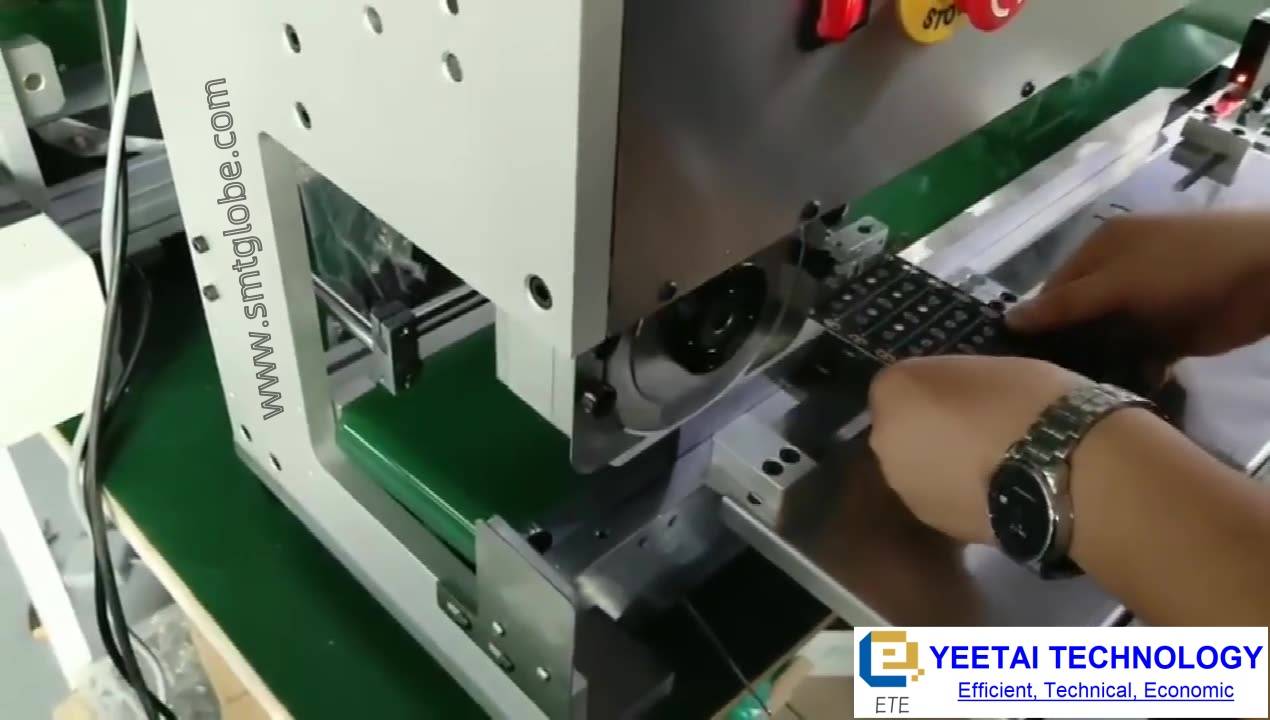

- Both sides of the circular blade are equipped with protective guards to prevent hand injuries during feeding.

- The mode switch is a standard switch, with continuous foot operation or jog mode. When operating in continuous foot mode and not reaching the specified travel distance, a flashing alarm light will indicate the need to cancel the alarm before continuing work.

Spare Parts Support:

Other machine models

LED PCB DEPANELING MACHINE ET3-700

AUTOMATIC PCB SEPARATOR ETE-500S

PCB DEPANELING MACHINE ETE-508-500