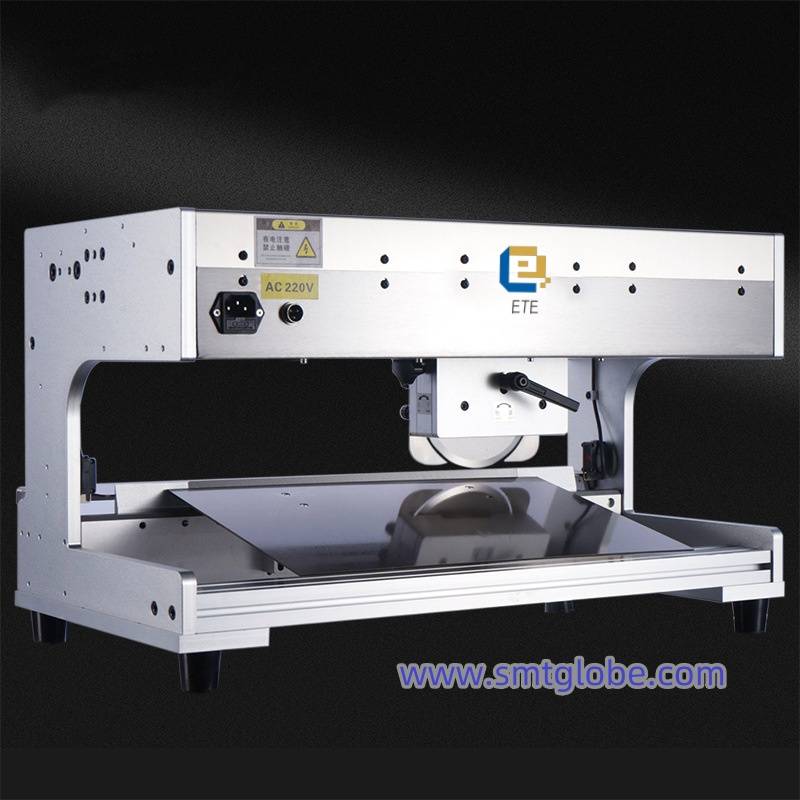

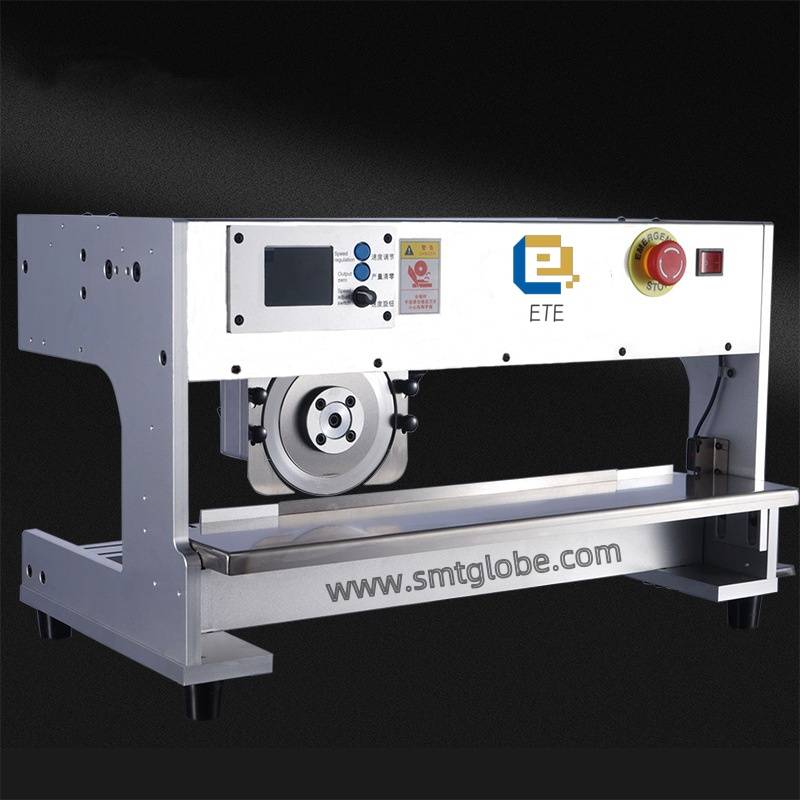

Our V-cut PCB depaneler offers precise and clean cutting for PCBs, ensuring high-quality results without damaging the boards. With adjustable blade speed, customizable blade length, and fine blade height adjustment, this machine is versatile and adaptable to various PCB thicknesses and V-CUT groove depths.

The moveable blade design reduces stress on the PCB. See above video. It also avoids solder joint cracking and component breakage. And the protective guards ensure operator safety. Invest in this reliable and efficient machine to improve production efficiency and product quality.

Features:

- Independently developed, microcomputer program control, precise positioning, and strong stability. V-cut PCB depaneler can cut a single board up to 480mm in length in one stroke.

- The cutting blade speed is adjustable, with high and low settings of 500mm/s and 300mm/s. A faster blade speed can improve product quality, producing clean and burr-free cuts.

- The blade travel distance is 0-500mm (blade length can be customized). The blade height can be finely adjusted by 0-2mm to accommodate various PCB thicknesses and resolve V-CUT groove depth issues. The operating table height is adjustable by 0-50mm.

- The blade travel can be set to stop at a designated point based on the board’s length, with the stop point manually set.

Equipment Specifications:

Model: ETE-508-360

Equipment Parameters: Main Machine Size: 610mmx360mmx375mm

Depaneling Thickness: 0.2-3.0mm

Maximum Depaneling Length: 360mm

Maximum Depaneling Width: Unlimited Board

Feed Speed: 300-500mm/second

Blade Material: SKD61 High-Speed Steel

Operating Temperature: 10-35℃

Storage Temperature: -20-50℃

Power Supply: 220V/110V, 50HZ/60HZ, 60W

Machine Weight: 30KG

Advantages:

- The PCB remains stationary when the cutting blade moves. Thus it avoids component damage caused by PCB movement (friction between PCB and workbench).

- This machine uses a moveable blade for cutting, reducing stress, preventing solder joint cracking and component breakage.

Spare Parts Support:

Other machine models

LED PCB DEPANELING MACHINE ET3-700

AUTOMATIC PCB SEPARATOR ETE-500S

PCB DEPANELING MACHINE ETE-508-500