V-CUT depaneling machines are specialized tools used in the PCB manufacturing industry to separate large panels into smaller pieces, facilitating subsequent processing and assembly. These machines are typically categorized into two types: online and offline models, each with distinct features and applications.

Online V-CUT Depaneling Machines are highly automated devices designed to work in conjunction with existing production lines. They operate through conveyor belts or tracks, automatically feeding PCB panels into the cutting station. Once the panels are separated, the individual pieces are directly conveyed to the next stage of manufacturing. This type of machine is characterized by its high efficiency, precision, and level of automation, making it ideal for high-volume production environments. However, online machines generally come at a higher cost and require skilled technicians for maintenance and operation.

In contrast, Offline V-CUT Depaneling Machines are typically manual devices used independently or in separate workspaces. With this type, operators place the PCB panels onto a workbench for cutting, which requires hands-on skill and experience. Offline machines are generally more affordable and easier to operate, making them suitable for smaller production batches. However, they have lower operational efficiency compared to their online counterparts.

Despite their differences, both online and offline V-CUT depaneling machines share similar capabilities, such as the use of tungsten steel or carbide blades for cutting, achieving a precision of ±0.1mm. Both machines can also customize the groove shapes according to various PCB requirements.

In summary, V-CUT depaneling machines play a crucial role in PCB processing, with the primary distinction between online and offline models being their level of automation and operational methods. Each type boasts common advantages like high precision, efficiency, and user-friendliness, catering to diverse production needs.

Understanding Online vs. Offline V-CUT Depaneling Machines

V-CUT depaneling machines are essential tools in the PCB manufacturing process, used to slice large panels into smaller sections for further processing. These machines primarily fall into two categories: online and offline, each presenting unique characteristics and applications.

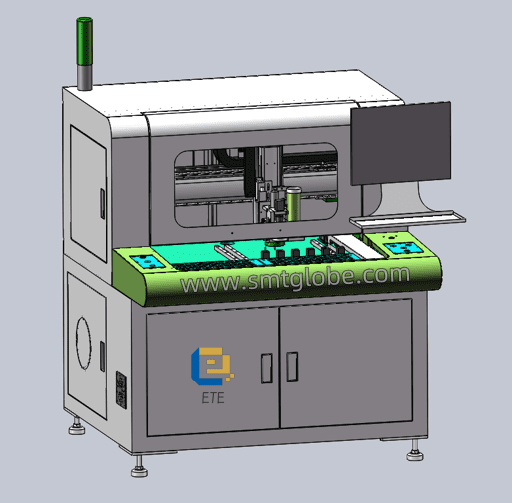

Online V-CUT Depaneling Machines are highly automated systems designed to integrate seamlessly with production lines. They utilize conveyor systems or tracks to automatically feed PCB panels into the cutting mechanism. After cutting, the individual PCB sections are efficiently transported to subsequent stages of assembly. These machines are known for their high efficiency, accuracy, and automation, making them suitable for large-scale production environments. However, they typically come with higher initial investments and necessitate skilled technicians for proper maintenance and operation.

On the other hand, Offline V-CUT Depaneling Machines operate as standalone units, often used in separate workspaces. This type requires operators to manually position PCB panels on a workstation for cutting, which demands a certain level of skill and experience from the user. Offline models are usually more cost-effective and user-friendly, making them ideal for smaller production runs, although they may not match the efficiency of online systems.

While these two types of machines differ in operation and automation, they share several key features. Both are capable of using tungsten steel or carbide blades for precise cuts, achieving an accuracy of ±0.1mm. Additionally, both can be adjusted to accommodate various groove configurations based on specific PCB requirements.

In conclusion, V-CUT depaneling machines play a vital role in the PCB fabrication process. The main differences between online and offline models lie in their automation levels and how they are used. Regardless of the type, both offer high precision, efficiency, and ease of use, making them valuable assets for various production scenarios.

We are experienced at PCB depaneling. Know more PCB depaneling solutions in our website: www.smtglobe.com