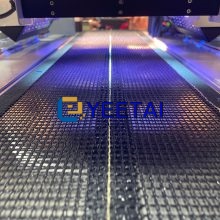

Our UV Curing Oven is an essential tool for drying PCBs (Printed Circuit Boards) after the conformal coating or glue dispensing process. Designed specifically for the UV curing of conformal coatings, this device enhances production efficiency and ensures optimal results.

Key Features of the UV Curing Oven:

- Advanced Control System:

- Features a PLC (Programmable Logic Controller) combined with a touchscreen and button control. Offering ease of operation.

- Efficient Conveyor System:

- Stainless steel chain conveyor with an effective width of 50-450mm.

- Conveyor speed is adjustable via the touchscreen. For special processing speeds.

- Variable Power Supply:

- Equipped with an electronic variable frequency power supply that allows power adjustment from 20% to 100%. Boosts energy usage.

- Customizable Specifications:

- Pre-reserved opening size for returning board lines of 590mm x 250mm to accommodate various production needs.

- Seamless Communication:

- Standard equipped with 2 SMEMA communication ports, facilitating easy integration into existing manufacturing setups.

- Real-time Temperature Monitoring:

- Includes a temperature sensing system that continuously collects and displays real-time data on the touchscreen interface, ensuring optimal curing conditions.

Specifications

| Type | In-line |

| Maximum Overboard Width | 450MM |

| Performance | Storage area + curing area + cooling area |

| Control method | Switch control (PLC+touch screen optional) |

| Transmission direction | L→R |

| Width adjustment range | 50~450MM |

| Rail load (including fixture) | 5.8㎏ |

| Rail fixing method | Front |

| Transportation belt height | 900±20mm |

| Transportation belt speed | 700~2000mm/min |

| Heating up time | 2min |

| Power supply | 380V |

| Weight | 200KG |

| On-board power consumption | One set of frequency conversion induction mercury lamp (1-6)KW |

| Recommended irradiation height | 100~120(mm) |

| Heat Dissipation Method | Fan cooling |

| Head Size | About 500*200*110(mm) |

| Weight of irradiation head | About 5Kg /pc |

| Dimension (L×W×H) | 1600×1000×1400mm |

Additional Features:

- User-Friendly Operation: The control method combines PCB cards with switch control and stepless adjustment for an easy user experience.

- Reliable UV Light Source:

- Delivers stable and dependable UV light through an independent light module, essential for uniform curing.

- Robust Transport Mechanism:

- Features a chain transmission with a constant speed and full closed-loop control for consistent performance.

- The high-strength guide rail design minimizes thermal deformation, ensuring high precision during the curing process.

- Manual width adjustment for the guide rails, facilitated by a panel control, provides convenience and ease of use.

- The innovative guide rail suspension system allows for easy adjustments while maintaining structural integrity.

Conclusion

The UV Curing Oven is a vital component in the PCB manufacturing process, particularly after the conformal coating stage. With its advanced technology, user-friendly controls, and reliable performance, it ensures high-quality curing results that meet industry standards.

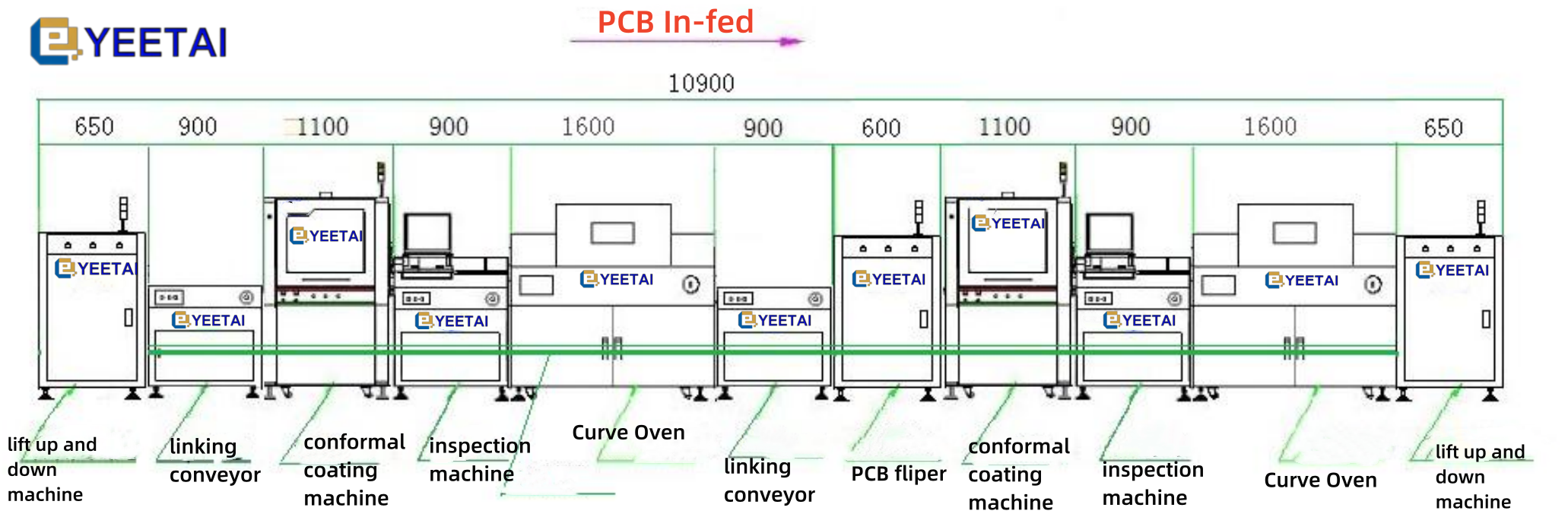

Conformal coating full line solution

We offer full line solutions of conformal coating process. You may read below pages.

Selective Conformal Coating Machine

Full conformal coating machine