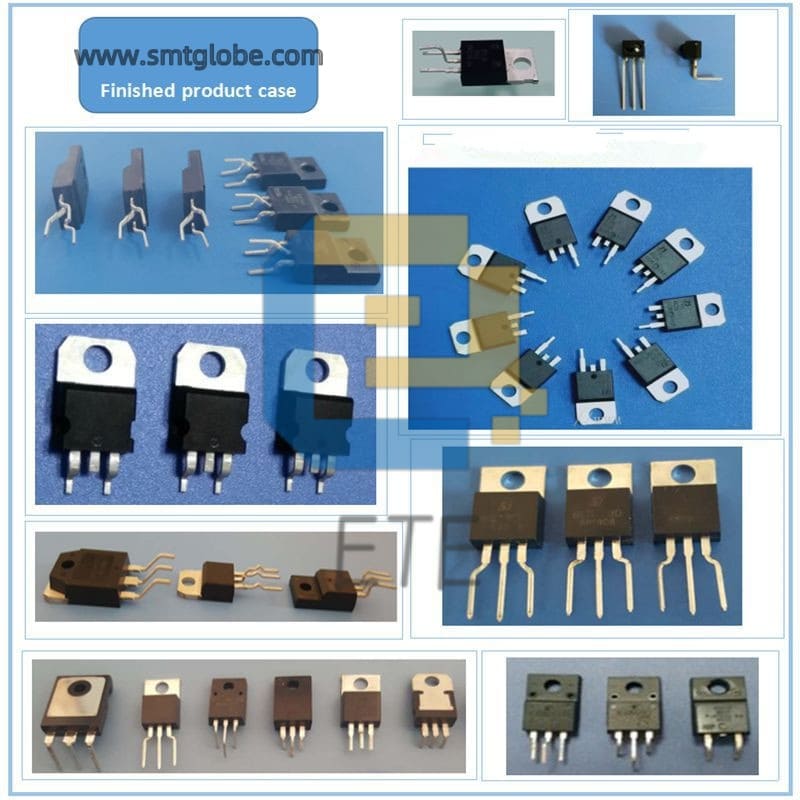

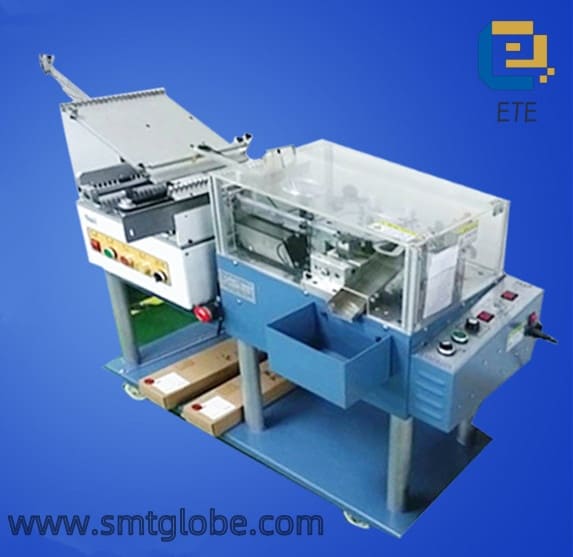

The Triode/IC lead former ETE-400 offers a versatile bending and shaping of tube-packed components,such as Triodes,Transistors and ICs.

It is controlled by PLC, making it easy to operate and capable of shaping and cutting pins without the need for tooling changes, meeting the personalized needs of users. The equipment also features a high-temperature powder spraying/surface anode/hard chromium process, with a compact appearance and durable performance. The component lead forming machine has high processing efficiency, processing 1 tube at 3sec. For more information about our lead forming machine, please contact us or visit our official website.

Benefits

- Triode/IC lead former increases production efficiency and cost savings in labor.

- The equipment has an easy machine set up with fully adjustable pitch & lead length.

- Easy and quick operation avoids time-consuming adjustment.Fast and efficient opeation.

- Compact appearance and small footprint. The radial lead former features space saving.

- It has durable performance for stable operation over time.

Features

- The machine comes with 20-tube automatic feeding system with direct vibration feed and discharge

- Full mechanical drive with motor structure

- The IC lead former’s circular disk design with precise cam divider positioning

- It is Convenient and offers quick operation

- IC lead former comes with small-sized PLC control system

- Intelligent control of photoelectric sensing and vibration plate feed makes it easy control.

- Triode/IC lead former supports adjustable forming height and foot cutting length

- Knob with reference scale for easy adjustment.

- The machine features low maintenance.Time saving.

Specification

- Model: ETE-400

- Product Name: Triode/IC lead former

- Blade Material: Japanese SKH11

- Power Supply: 220VAC 50HZ

- Electrical Components: Omron/Mitsubishi

- Sheet Metal Process: High-Temperature Powder Coating/Surface Anodizing/Hard Chrome

- Dimensions: L1150xW700xH950mm

- Weight: 150Kg

- Equipment Usage: Foot cutting and forming of transistors, ICs, bridge stacks, and other tubular components

- Capable of handling 20-tube packaging components simultaneously