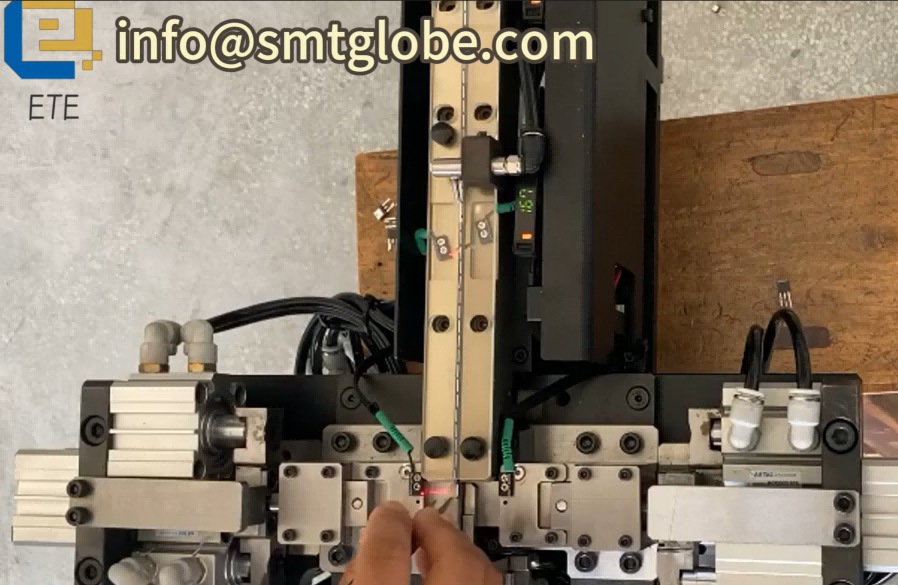

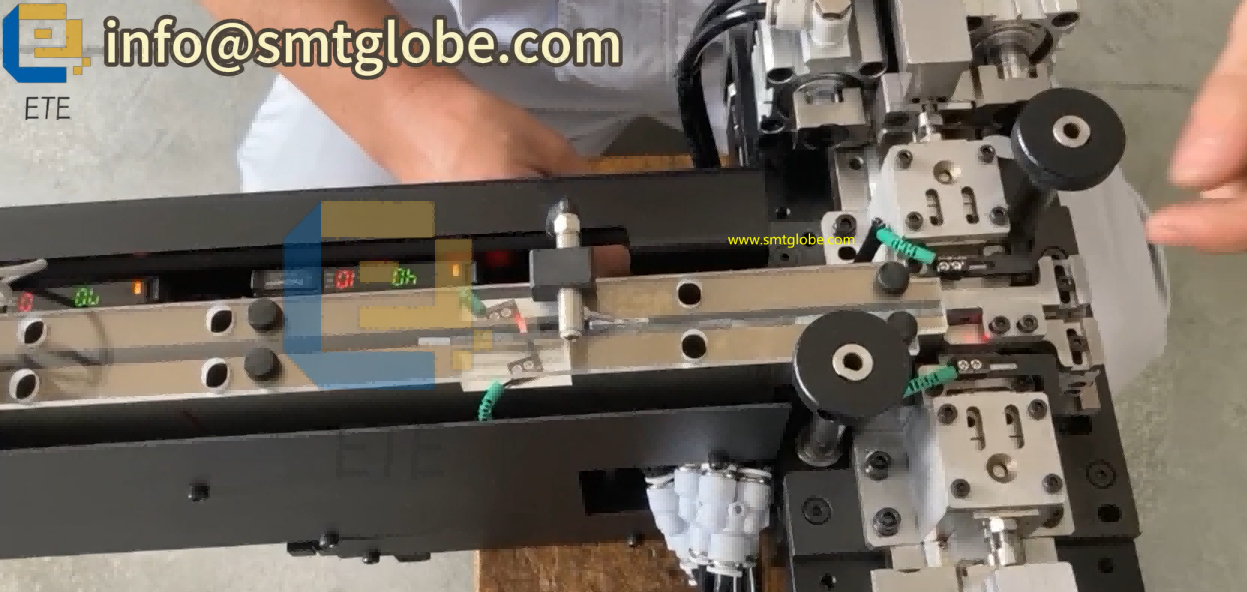

The transistors tube feeder ETE-TF02automates component feeding of ICs, connectors, and triodes etc. to SMT pick and place machines. Besides cutting leads, the feeder has a creative function to bend component leads into all kinds of shape. Our tube feeder enhances the utility of SMT line already implemented in an OEM EMS factory. Improve efficiency, reduce labor costs, and maximize the utility of your SMT line. Explore our tube feeder‘s technical specifications and features now.

Specifications

| Model | transistors tube feeder | ETE-TF02 |

| Dimensions | length x width x height | 1350x92x115mm |

| weight | 25Kg | |

| Applicable materials | Material type | Relays, terminals, transformers, square capacitors, round capacitors |

| Dimensions | 3x3x3mm-25x25x25mm | |

| tube | PVC material pipe, aluminum pipe | |

| Barrel Length | 200-650mm | |

| Barrel wall thickness | >0.6mm | |

| Structural part | Feeding method | Incoming material in tubes, multi-tube stacking |

| Feeding power | motor drive spring | |

| Material positioning method | Optical fiber sensing + software compensation | |

| a fixed way | Positioning key + pressing block, supporting other fixed structures | |

| Receiving tube | evacuation by cylinder, recovery box at the bottom | |

| Electrical part | Operating Voltage | 24V |

| Average Current/Peak Current | 4A/6A | |

| working pressure | 0.4-0.6Mpa | |

| Operation method | key operation | |

| Host computer connection | 8 core ø16mm aviation plug | |

| communication method | Support IO communication or self-control without communication | |

| software control | Based on ARM (STC32) | |

| drive mode | stepper motor | |

| Motor type | Type 57 | |

| motor speed | 600 rpm | |

| Feeding part | Feeding speed | 0.8S |

| Feed channel | Single-channel feeding (double-channel feeding can be customized) | |

| speed gear | Four gears adjustable | |

| Feeding accuracy | ±0.5mm | |

| Test record | Feed test | Realize 1000 times of continuous feeding without exception |

| Aging test | Continuous operation for 48 hours without exception | |

| service life | 5 years’ service life | |

| Cutter life | 4 million times bending life |

Features

- The transistors tube feeder loads various tube-packaged materials for DIP components onto different pick-and-place machines (or modified similar equipment), enabling automatic insertion, reducing manual labor, and increasing the utilization rate of pick-and-place machines.

- By mounting tube-packaged materials on feeders, the transistors tube feeder supplies non-standard equipment, reducing the design cycle for non-standard equipment and enhancing its stability and usage rate.

- It applies tube-packaged feeders to automatically insert transistors and heat sink screws, facilitating the automatic insertion of transistors.

- Collaborating with robotic arms, the tube-packaged feeder automates production processes, replacing manual labor.

- Users can choose tube-packaged feeders of different sizes and models according to site requirements.

- Select tube feeders of various sizes based on site specifications.

- Compatible with a wide range of popular machine brands, including Fuji, Juki, Panasonic, Yamaha, Siemens, Samsung, Mydata, and more.

- The transistors tube feeder is powered by a motor, enabling efficient product transportation.

- It incorporates capabilities to shape and trim material pins, enhancing the overall manufacturing process.

- This innovative feeder allows for the stacking of multiple tube-packaged materials, facilitating seamless and unmanned tube replacement operations.

- Additionally, it features a material pin recycling function, where excess pins are collected and held in position for retrieval by the upper computer system.

- Furthermore, the transistors tube feeder is versatile and can be seamlessly integrated with a wide range of pick-and-place machines for enhanced production efficiency.

Advantages:

- Labor-saving: transistors tube feeder automates component transport and placement, reducing the need for manual labor.

- Enhanced efficiency: It maximizes the utility of your SMT line without the need for additional machinery, saving costs and streamlining operations.

- Versatile compatibility: The transistors tube feeder is suitable for a wide range of tube-packed materials, including triodes, connectors, and ICs. Compatible with leading machine brands including Fuji, Juki, Panasonic, Yamaha, Siemens, Samsung, and Mydata.

- Customizable: Choose from different sizes to match your specific production requirements.

- Longevity: Built for durability with a 5-year service life and a 4-million-times bending life for the cutter.

- Advanced pin bending and cutting: ETE-TF02’s in-built device allows for precise pin forming and cutting based on user specifications, saving time and effort in component preparation.

- Customizable pin shaping: Tailor component pins to exact requirements, improving compatibility and fit during assembly.