For electronics manufacturers in need of THT component Feeders, purchasing used JUKI pick-and-place machines offers numerous advantages. While investing in new machines can be budget-intensive and involve long lead times, as well as challenges in hiring engineers and sourcing parts, opting for second-hand equipment provides several benefits.

Used pick-and-place machines typically allow for quicker returns and involve lower risks and investments. Furthermore, today’s second-hand machines demonstrate impressive speed and efficiency compared to older SMT pick-and-place machines. They can produce more units in the same time frame and are capable of handling components larger than 0603 in size; however, smaller components may not be suitable for this type of equipment. Additionally, second-hand pick-and-place machines can also be utilized for various types of lighting products, including LED strips, ceiling lights, and bulb lights, making them an excellent choice for customers seeking high returns on low investments.

Selecting THT component Feeders

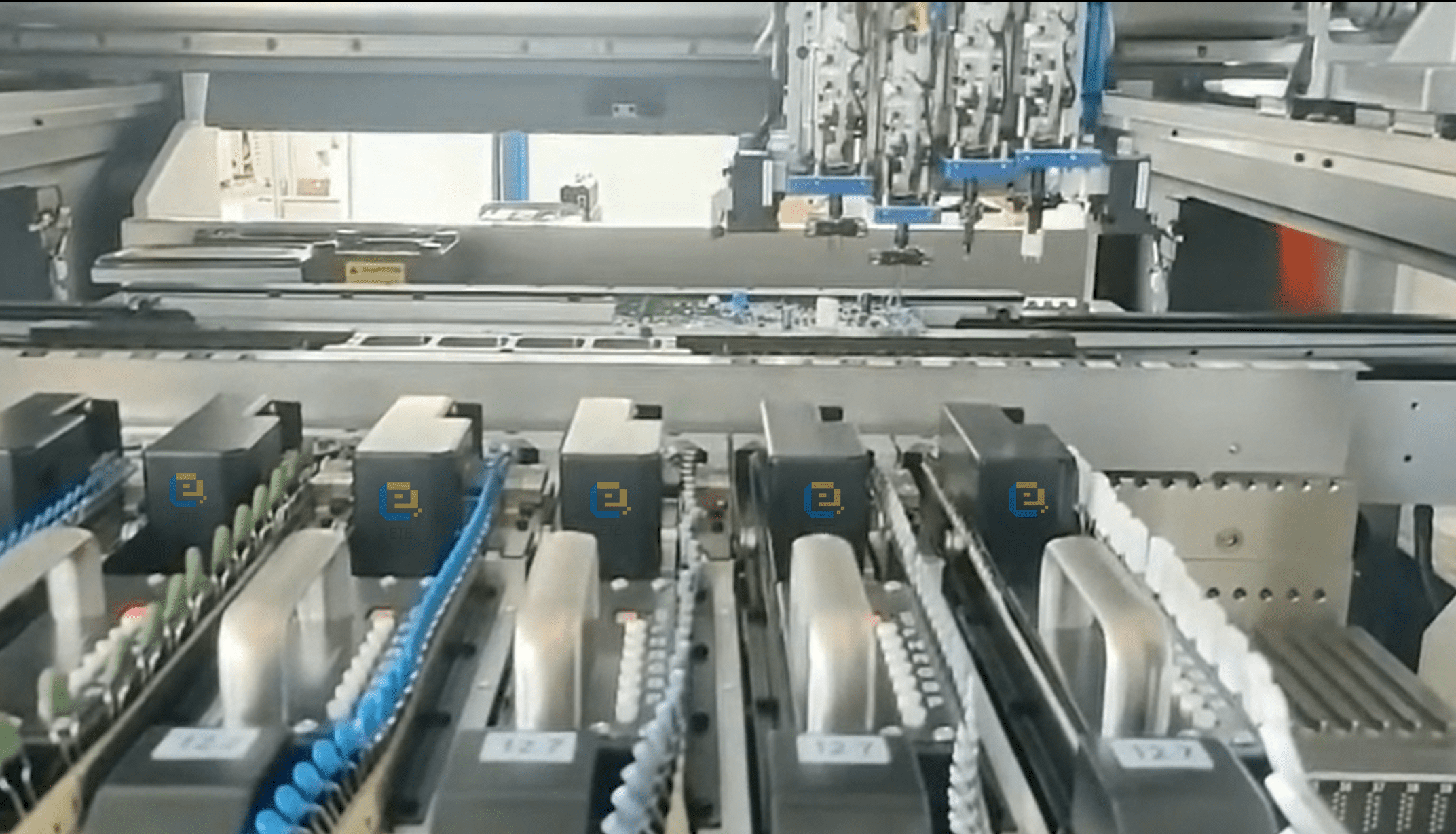

When it comes to selecting the right THT component Feeders, the variety available can be overwhelming. Common types include vibratory bowl feeders, pick-and-place feeders, vertical and horizontal tape feeders, tube feeders, label feeders, and solder paste feeders. To make an informed decision, consider the following factors:

- Component Compatibility

Start by assessing the type of components you will be working with. Choose a plugin feeder tailored to accommodate your specific component types and sizes. The right feeder will improve efficiency and reduce handling time. - Feeder Speed and Versatility

Consider the required speed of the feeder to match your production goals. A feeder that offers both speed and versatility will ensure that it can handle a variety of components as your production needs evolve. - Maintenance and Repair Costs

Evaluate the maintenance and repair costs associated with the feeders. Opting for models that have a reputation for reliability and ease of maintenance can save you time and money in the long run.

Conclusion

In summary, choosing the right THT component Feeders is crucial for optimizing your electronics manufacturing process. By selecting appropriate equipment based on component compatibility, speed, versatility, and maintainability, you can significantly enhance production efficiency and ensure a higher return on investment.

If you need SMT feeding solutions, we are here to help.

At YEETAI, we produce all kinds of feeder to upgrade SMT machines.