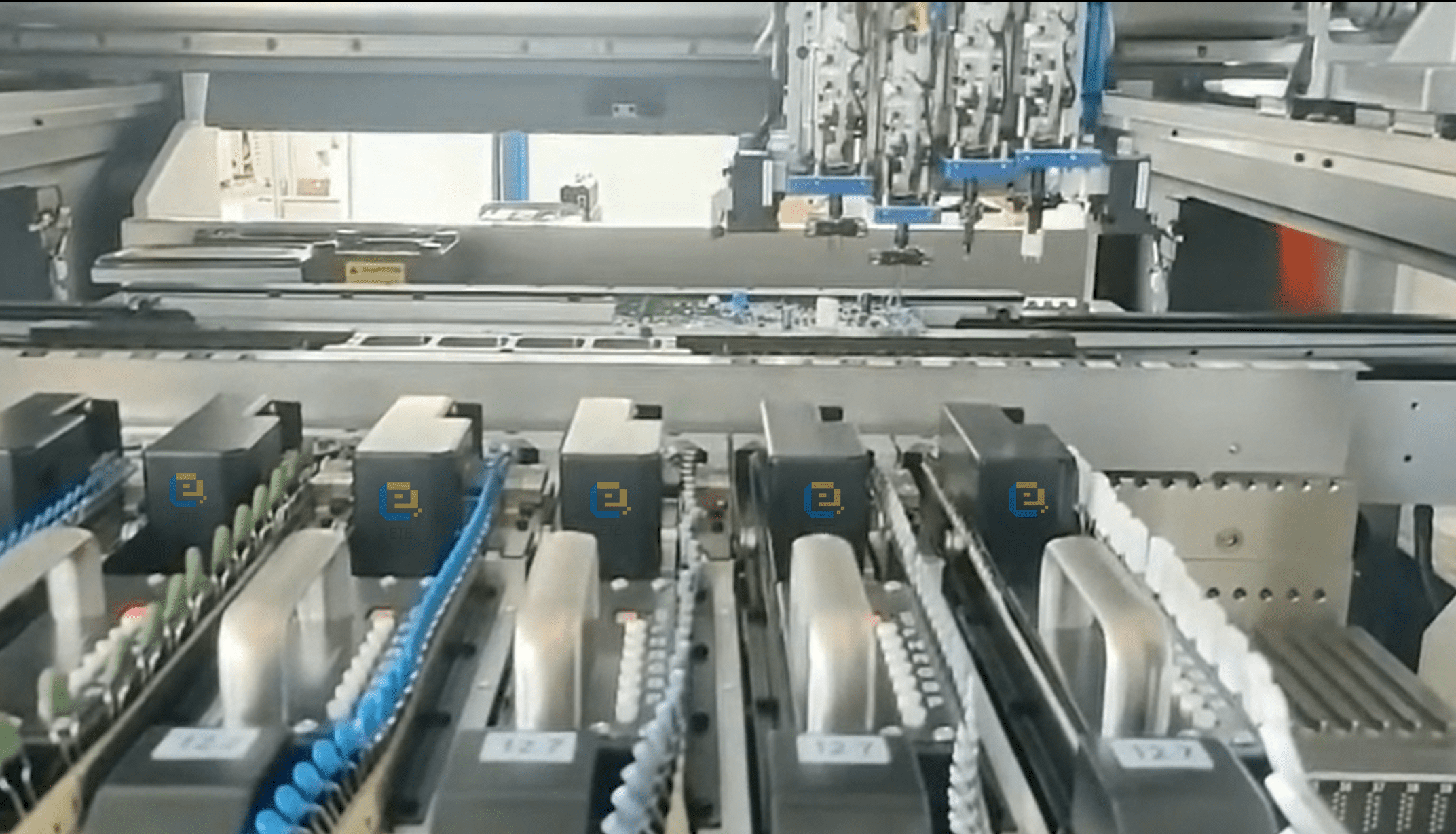

SMT (Surface Mount Technology) placement machines are advanced automated devices primarily used for the assembly of electronic components in the manufacturing of electronic products. As the demand for precision, speed, and integration in component assembly has increased, these machines have significantly enhanced industry productivity and provided a reliable quality assurance for the development of electronic intelligent manufacturing. During the operation of placement machines, electronic components must be accurately mounted onto PCB (Printed Circuit Board) layouts. This process requires a precise and continuous supply of components through an auxiliary tool known as a feeder, or feed mechanism.

Understanding the operation of SMT feeders is essential for ensuring their consistent reliability and stability over time. This article outlines the correct procedures for installing, modifying, and maintaining SMT feeders to optimize performance.

1. Installation of the Feeder

To ensure a proper setup of the SMT feeder, follow these detailed steps:

- Open the material cover and the tape guide on the feeder.

- Position the material reel on the feeder reel rack.

- Thread the upper tape of the material and the transport tape through the guide slots and the main machine framework. Remove the upper cover at the leading edge of the tape until you reach the extraction area, then place the transport tape into the guide slot.

- When the chain wheel grips the transport tape in the movement slot, pull down the tape guide so that it is flat against the transport tape. Finally, adjust and confirm that the transport tape is correctly set within the grasp of the chain wheel.

- Secure the fixed separation of the upper cover tape between the gear and the forming gear for removal.

- Use the rotary arm to push the tape to the pickup position.

2. Modifying the Feeder Transmission Spacing

Adjustment of the feeder’s transmission spacing is crucial for accommodating different component types:

- The 8mm tape feeder has two pitch options: 2P and 4P, requiring dedicated feeders for each type.

- The 12mm tape feeder can be adjusted for 4mm, 8mm, or 12mm spacing based on the component type.

- The 16mm tape feeder can switch between 4mm, 8mm, 12mm, or 16mm transmission distances.

- The 24mm tape feeder allows for spacing settings of 4mm, 8mm, 12mm, 16mm, or 20mm.

- Use a flat-head screwdriver to loosen the existing position, then adjust the handle to the required spacing (4, 8, 12, 16, or 20) before tightening the screws again.

3. Installing and Removing the Feeder from the Base

To successfully install or remove the feeder from its base, follow these steps:

- Prior to installation, thoroughly sweep the base of any debris and foreign materials using a brush.

- Each base slot has a unique identification number; insert the feeder into the correctly numbered slot as per the technician’s positioning table.

- Ensure that the positioning pin at the lower front of the feeder aligns with the vertical plate, applying appropriate force to push it forward.

- Push the handle forward to secure the feeder to the base and verify it is firmly attached.

- To remove the feeder from the base, first confirm that the equipment is in a stopped state. Once confirmed, pull the handle backward to release the feeder, then hold the handle and move it backward until it is detached.

4. Maintenance and Inspection Items

Regular maintenance and inspection are vital for the longevity of SMT feeders:

- Check all screws on the feeder monthly for looseness.

- Lubricate frequently moving parts monthly with appropriate oil.

- Clean impurities from the chain wheel area daily.

- Demagnetize the shuttle area monthly.

- Inspect the LED light status daily.

5. Precautions

To ensure optimal operation and prevent damage, observe the following precautions:

- Avoid placing the feeder in magnetic fields.

- Ensure no collisions occur between the feeder and other objects.

- Do not disassemble multiple feeders at once or stack them.

- Maintain cleanliness of the feeder to prevent faults, reducing downtime due to feeder issues.

- Handle the feeder gently during installation and removal to minimize damage to components.

Conclusion

Proper operation and maintenance of SMT feeders are essential for enhancing the efficiency and reliability of PCB assembly processes. By adhering to recommended practices for installation, spacing adjustment, and regular maintenance, operators can ensure that feeders remain an effective and integral part of modern electronic manufacturing. This proactive approach not only ensures high-quality production but also contributes to the overall advancement of intelligent manufacturing in the electronics industry.

By implementing these practices, businesses can minimize the risk of production interruptions and maximize the efficiency of their SMT assembly lines.

At YEETAI, we produce all kinds of feeder to upgrade SMT machines.