Surface Mount Technology (SMT) has emerged as one of the most popular techniques and processes in the electronics assembly industry. This technology allows for the mounting of surface-mounted components (SMCs/SMDs). They are either leadless or have short leads, directly onto the surface of printed circuit boards (PCBs) or other substrate materials. These components are then soldered using methods such as reflow soldering. It results in highly efficient circuit assemblies.

Advantages of SMT

SMT is renowned for its numerous benefits, including:

- High Assembly Density: The compact nature of SMDs allows for denser configurations, enabling more functionality in less space.

- Reduced Size and Weight: SMD components typically occupy just one-tenth the volume and weight of traditional through-hole components. This results in a reduction in the overall size of electronic products by 40% to 60%, and a weight decrease of 60% to 80%.

- Compatibility with Portable Devices: Given the rising demand for portable electronic devices, SMT has become the go-to process in the electronics manufacturing sector.

Our Peripheral Equipment Solutions

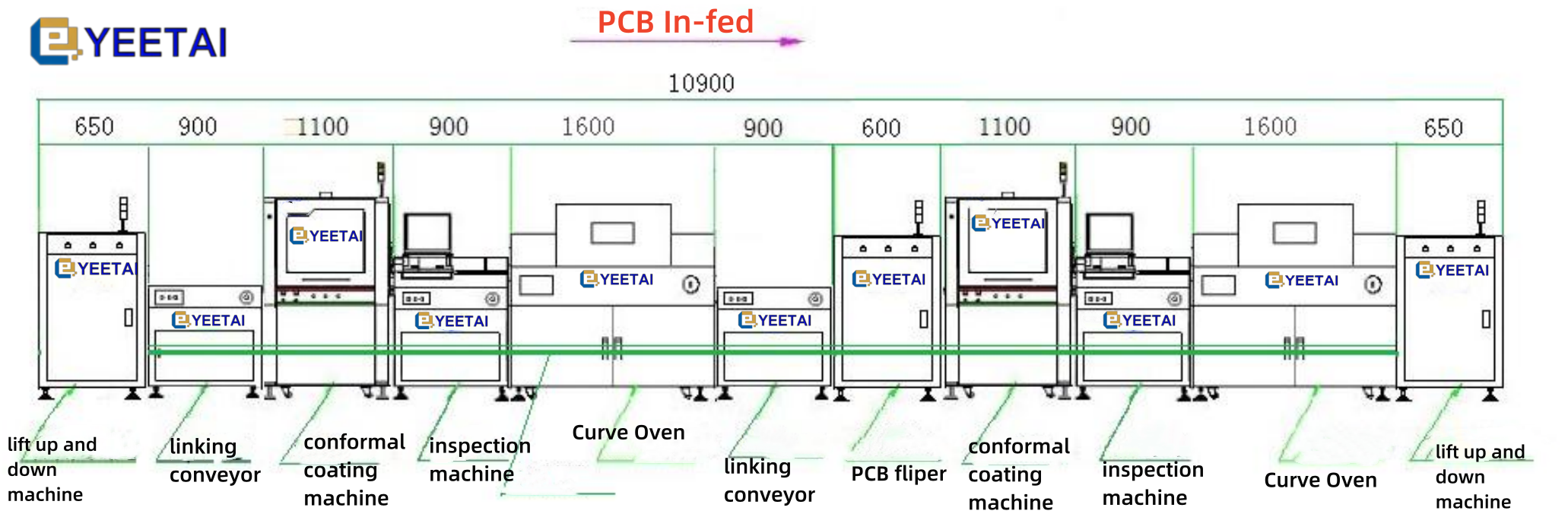

At YEETAI, we recognize that efficient SMT assembly processes require not just high-quality components, but also the right peripheral equipment to support these operations. We offer a range of essential equipment designed to enhance your SMT processes, including:

- Interface Stations: Designed for seamless integration between different stages of the assembly line, our interface stations optimize workflow and minimize downtime.

- Pick and Place Machines: Precision machinery that accurately places SMD components onto PCBs, ensuring alignment and reliable soldering.

- De-paneling Machines: Perfect for removing individual PCBs from panels, our de-paneling machines enhance the efficiency of your assembly line.

- Cleaning Machines: Essential for maintaining cleanliness and ensuring optimal solder quality, our cleaning machines effectively remove flux residues and contaminants.

- Board Handling Equipment: Equip your factory with advanced board handling systems to streamline transportation and improve the overall workflow.

Why Partner with Us?

- Expertise in SMT Solutions: With extensive experience in the electronics manufacturing sector, we understand the complexities and challenges SMT factories face.

- Comprehensive System Offerings: Our range of peripheral equipment is designed to work seamlessly together, ensuring a smooth assembly process.

- Quality Assurance: We prioritize quality in every aspect of our equipment, ensuring that your production meets the highest industry standards.

- Dedicated Support: Our team of experts provides ongoing support and guidance to help you choose the right equipment and maintain optimal operation.

Conclusion

Surface Mount Technology is an essential process in modern electronics assembly, offering significant advantages in size and efficiency. At YEETAI, we are dedicated to providing SMT factories with the peripheral equipment needed to enhance their assembly processes. Contact us today to learn more about our solutions and how we can help you achieve greater efficiency and reliability in your SMT operations.

We can help to simplify and qualify your PTH PCB assembly process. We are also helpful at Through-hole process.