SMT (Surface Mount Technology) feeders, commonly referred to as placement machine feeders, play a critical role in the assembly processes of electronic components. Their primary function is to supply materials to the placement head, which accurately picks up electronic components through nozzles or grippers. SMT feeders are not standard components included with placement machines or insertion machines; they must be purchased separately, making them an essential part of both the placement machine and the SMT process. This article will provide an overview of the structure and classification of SMT feeders.

Structure of SMT Feeders

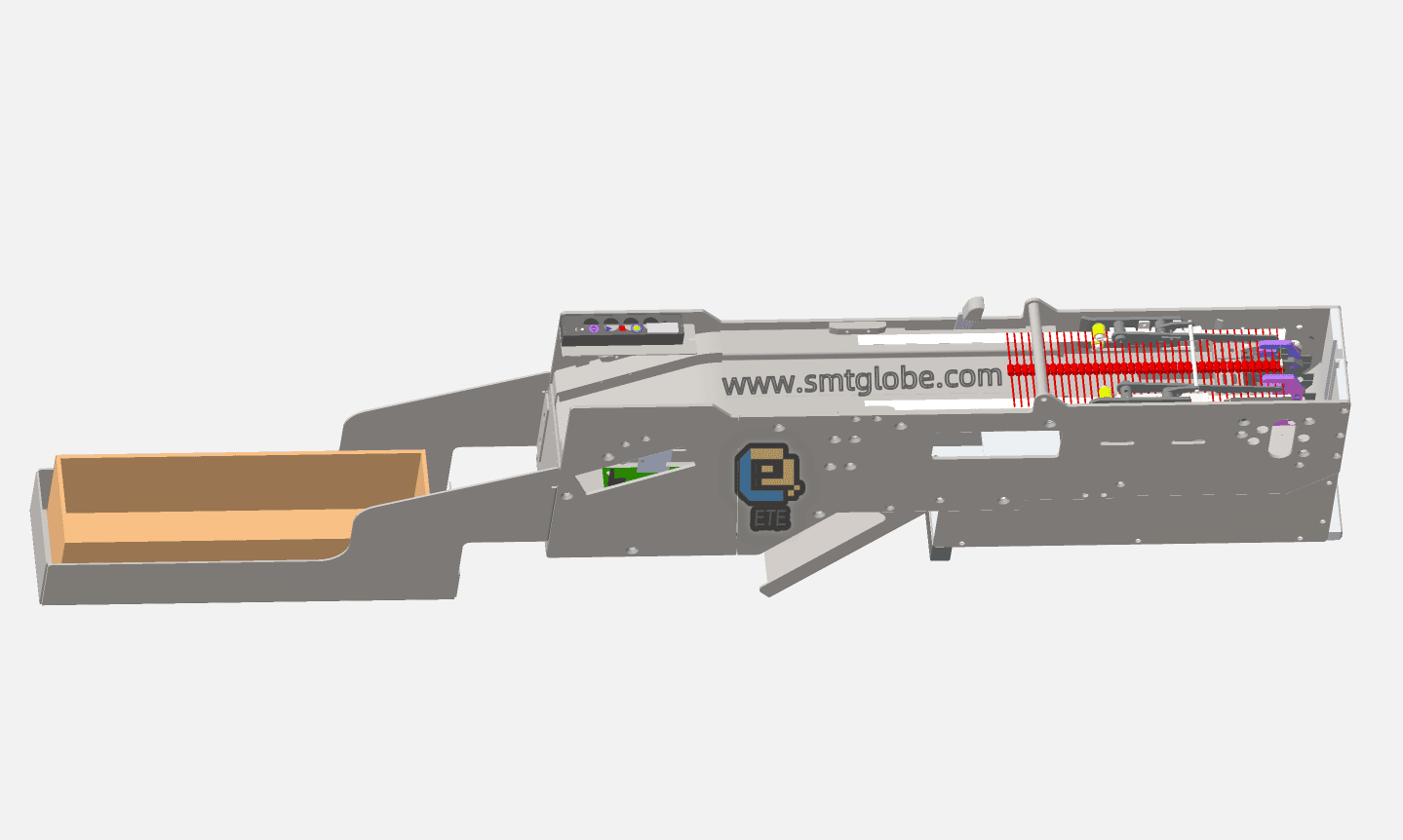

The material tape is secured onto the shaft of the SMT feeder and enters the feed slot via a pressing device. The upper tape is separated from the carrier base by a separating plate and is fixed onto the take-up wheel. The synchronization holes on the carrier base engage with the teeth of the synchronization wheel, allowing the material to move toward the end of the SMT feeder.

Once the feeder is loaded into the machine, the placement head follows programmed instructions to pick up components. A “feeding roller” sends a mechanical signal to the handle, causing the synchronization wheel to rotate an increment, thereby positioning the next component for pickup.

If the feeder experiences a high rate of component ejection, a feeder calibration instrument can be used for adjustment.

In SMT production, the placement machine or insertion machine receives commands to pick components from the feeder at designated positions. Due to various packaging methods for different components, different feeders are required. Below are the mainstream types of SMT feeders currently available in the market.

Classification of SMT Feeders

1. Tape Feeders

Tape feeders are the most commonly used standard feeders in placement machines. Traditional designs include wheel-type, claw-type, pneumatic, and multi-spacing electric feeders. The latest developments have introduced high-precision electric feeders, which offer improved transfer accuracy, faster feeding speeds, more compact designs, and enhanced stability, thereby significantly increasing production efficiency.

2. Tray Feeders

Tray feeders can be categorized into single-layer and multi-layer structures. A single-layer tray feeder is installed directly on the feeder rack of the placement machine, occupying multiple slots, making it suitable for applications with fewer tray-type components. In contrast, a multi-layer tray feeder consists of several automatic transfer trays, which take up less space and provide a compact design, ideal for applications with a larger quantity of tray-style components. These feeders are particularly suited for various IC components.

When using tray-type materials, it is crucial to protect larger surface-mounted components to prevent mechanical and electrical damage during transport and operation. For components like TQFP, PQFP, BGA, TSOP, and SSOP, tray dimensions can reach up to 150mm x 330.2mm with a height of 25.4mm. Interestingly, tray feeders can not only supply components to the placement machine but also serve as dispensing stations for valuable components.

3. Vibration Feeders

Vibration feeders, also known as bulk box feeders, operate by allowing components to be freely placed inside designed plastic boxes or bags. Vibration feeders transport components sequentially into the placement machine. This method is commonly used for MELF (metal electrode leadless face) and small outline components, ideal for non-polar rectangular and cylindrical components, but unsuitable for polarized components. One notable feature of vibration feeders is their higher cost.

4. Tube Feeders

Tube feeders typically utilize vibrating mechanisms to ensure that components within the tube continually move towards the pickup position at the placement head. This type of feeder is commonly used for supplying PLCC (Plastic Leaded Chip Carrier) and SOIC (Small Outline Integrated Circuit) components. Tube feeders effectively protect component pins, but they may have less stability and standardization, resulting in lower production efficiency compared to other types.

Conclusion

SMT feeders are one of the most critical accessories of placement machines and significantly influence placement capabilities and production efficiency in assembly technology. Some SMT placement machines are even marked by the number of SMT feeders they can accommodate. Understanding the structure and classification of SMT feeders is essential for optimizing SMT operations and ensuring high-quality assembly processes.

By investing in the appropriate type of feeder for your production needs, you can enhance efficiency and improve the overall quality of electronic manufacturing processes.

At YEETAI, we produce all kinds of feeder to upgrade SMT machines.