Testing Requirements

During the manufacturing process, PCBs (Printed Circuit Boards) often need to undergo depaneling, which involves cutting a large PCB into multiple individual circuit boards. Traditionally, it is said that punch-type PCB depanelers induce less stress, while laser depanelers create no stress at all. However, several specific factors affect the stress levels in PCB depaneling operations.

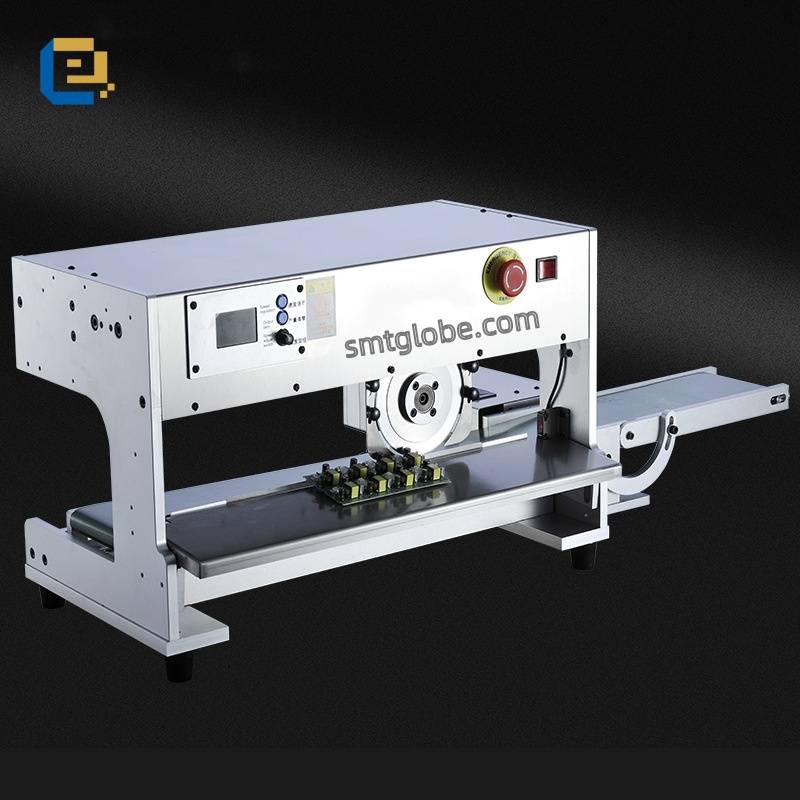

In a moveable blade PCB depaneler, the PCB substrate remains stationary while a circular blade slides across it. This configuration helps ensure that electronic components on the substrate are not damaged during the cutting process, thus influencing the stress generated by the depaneling machine. Additionally, factors like the sliding speed of the circular blade, the depth of the V-groove, the wear of the cutting tool, and the precise adjustment of the gap between the upper circular blade and the lower straight blade all contribute to the overall stress experienced during depaneling.

Since depaneling can lead to stress concentration, which may compromise the reliability of the circuit boards, it is essential to conduct stress testing for PCBs during this process.

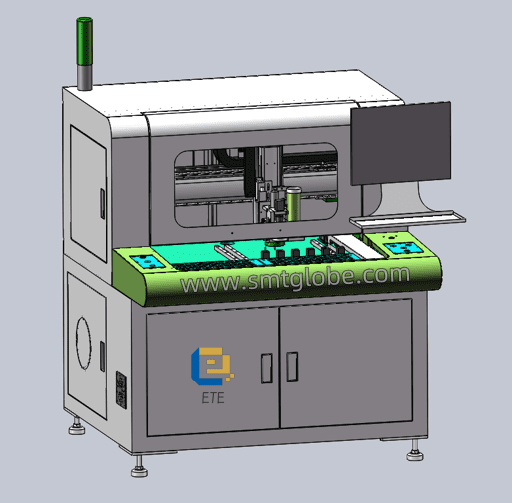

Testing Subject: Moveable Blade PCB Depanelers

Before carrying out stress testing on PCBs using a moveable blade depaneler, it is crucial to analyze the PCB design through the following aspects:

- Material Selection: Determine the materials for the PCB according to the design specifications, including the substrate and copper foil. Different materials possess varying physical and mechanical properties that can significantly influence the results of the stress tests.

- Layer Analysis: Evaluate the different layers of the PCB to decide if stress testing is necessary. Generally, if the PCB has multiple layers or dense routing, conducting a stress test is highly advisable.

- Circuit Layout Analysis: Analyze the layout of the circuit to identify optimal depaneling locations and methods. It is best to select areas with simpler circuit layouts and shorter connections for depaneling to minimize potential stress concentrations.

After completing the testing, the collected data should be thoroughly analyzed to ascertain whether the depaneler has induced any damage to the PCB. This comprehensive approach to stress testing is vital in ensuring the reliability and performance of PCBs in their final applications.

By understanding and controlling the various factors involved in PCB depaneling, manufacturers can enhance the integrity of the final product and reduce the likelihood of failures in electronic systems.

We are experienced at PCB depaneling. Know more PCB depaneling solutions in our website: www.smtglobe.com