In today’s manufacturing environment, understanding static electricity and its implications is crucial for safety and operational efficiency. Our Static Electricity Management Training program is designed to equip your employees with essential knowledge and practical skills to effectively manage static electricity hazards.

Why Static Electricity Management is Important

Static electricity can lead to serious electrostatic discharge (ESD) incidents that damage sensitive electronic components, leading to costly repairs and production downtime. By implementing effective static electricity management practices, your factory can minimize these risks, ensuring both workplace safety and product reliability.

Training Content Overview

Our training program covers the following key areas:

1. Fundamentals of Static Electricity

- Understanding Static Generation: Learn how static electricity is generated, including contact, friction, and induction processes.

- Recognizing Hazards: Understand the risks associated with static electricity and how it impacts electronic components and equipment.

2. Static Electric Protection Measures

- Grounding Techniques: Explore effective grounding methods to minimize static buildup.

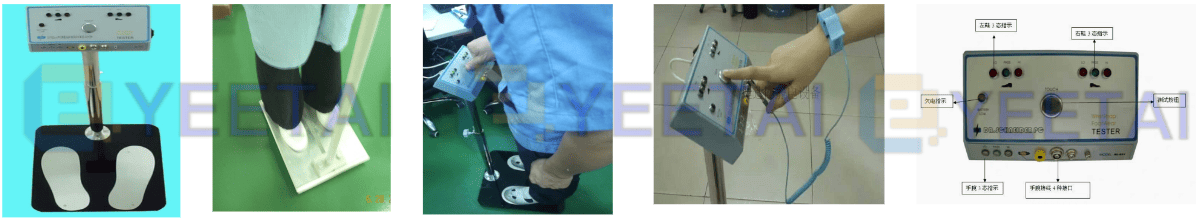

- Protective Equipment: Identify various personal protective equipment (PPE) and tools designed to prevent ESD.

3. Usage of Anti-Static Devices

- Hands-On Training: Get practical experience with anti-static tools and garments. Learn the correct usage of anti-static wrist straps, mats, and ionizers.

4. Safe Operating Procedures

- Developing Standard Protocols: Learn how to create and implement static electricity safety protocols in daily operations.

5. Static Monitoring and Testing Techniques

- Tools and Techniques: Discover methods for monitoring static levels, including the use of static testers and proper data interpretation.

6. Emergency Response Plans

- Incident Management: Understand the steps to take in case of a static ESD incident, including communication protocols and immediate response actions.

7. Employee Awareness and Education

- Building a Safety Culture: Engage employees by highlighting the importance of static electricity awareness and safe practices.

8. On-Site Practical Guidance

- Real-World Application: Facilitators will provide on-site support to address practical challenges and ensure skill transfer during training.

9. Case Studies and Lessons Learned

- Real Incident Analysis: Analyze past static-related incidents to glean insights and improve future practices.

10. Ongoing Training and Assessment

- Regular Refresher Courses: Implement a structured retraining schedule to ensure that employees remain aware of static management best practices.

Tailor-Made for Your Factory

Our training program can be customized based on your factory’s specific needs and protocols. Whether you are in electronics manufacturing, pharmaceuticals, or any industry susceptible to static hazards, our training ensures a safe and efficient working environment.

Conclusion

Investing in Static Electricity Management Training is crucial for your factory’s safety and efficiency. By empowering your employees with knowledge and practical skills, you not only protect your assets but also foster a culture of safety and accountability.

Get Started Today!Contact us to learn more about our static electricity management training programs. Visit our website at www.smtglobe.com or email us at info@smtglobe.com for more