In the SMT (Surface Mount Technology) assembly process, approximately 60-70% of soldering defects arise from poor solder paste printing. The quality of solder paste printing directly impacts the yield of SMT assembly. Therefore, ensuring high-quality solder paste application is crucial to minimize defects related to poor printing.

Common Defects in Solder Paste Printing

Several issues can occur during the solder paste printing process, including:

- Solder Paste Collapse

- Improper Coverage Area

- Solder Bridges

- Solder Paste Misalignment

- Solder Paste Leaking

- Poor Solder Paste Definition

- Solder Paste Pitting or Scraping

- Dirty or Blurry Solder Paste

- Excessive Solder Paste Volume

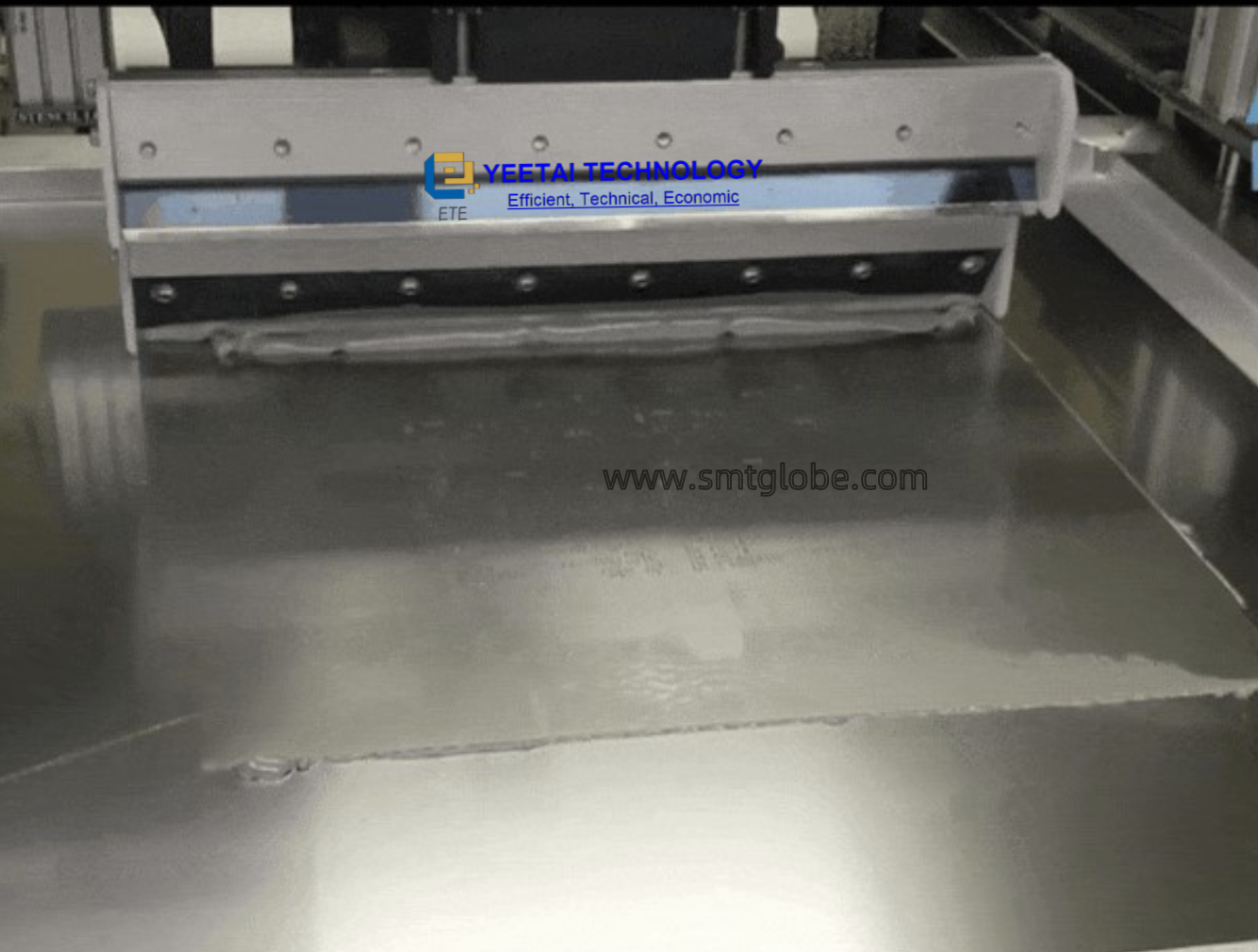

1. Solder Paste Collapse

Solder paste may collapse after printing, causing the edges to sag and extend towards adjacent pads. This can lead to solder bridges if not corrected promptly.

Cause: Excessive squeegee pressure can over-compress the solder paste, causing it to flow into the gap between the stencil and PCB. This can cause neighboring pads to connect, resulting in collapse.

2. Improper Coverage Area

The coverage area should ideally match the stencil’s opening size. Insufficient coverage can lead to insufficient solder, while excessive coverage can cause solder bridges.

Cause: Poor stencil release or inadequate printing parameters can result in uneven solder paste application, leading to either insufficient or excessive coverage.

3. Solder Bridges

Solder bridges, or wet bridging, occur when solder paste connects adjacent pads. During reflow, surface tension may sometimes separate them, but if they don’t, short circuits can occur.

Cause: Solder paste collapse or poor control of the paste’s characteristics, such as metal content or particle size, can exacerbate this issue. Inadequate printing parameters also play a role.

4. Solder Paste Misalignment

Misalignment occurs when printed paste doesn’t coincide with the actual pad positions, which can lead to bridging or solder accumulation on the solder mask.

Cause: Insufficient clamping or support for the PCB, incorrect parameter settings, or dimensional tolerances can create misalignment between the stencil and PCB.

5. Solder Paste Leaking

Leaking occurs when the solder paste applied is less than 80% of the stencil’s opening area, resulting in inadequate solder coverage.

Cause: Squeegee speed may be too fast, which causes the solder paste to slide rather than fill openings, particularly in fine-pitch applications.

6. Poor Definition of Solder Paste

The solder paste should maintain a clear, distinct profile. Any irregularities such as “dog ears” can cause defects in solder formation.

7. Solder Paste Pitting or Scraping

Pitting refers to the removal or hollowing of solder paste from the stencil openings during the printing process.

Cause: A hardened squeegee can deform and dig into the stencil, or an oversized stencil opening may exacerbate paste loss.

8. Dirty or Blurry Solder Paste

Contamination can lead to unclear solder points or residue on the PCB, causing bridging or other defects.

Cause: Blockages in the stencil openings or print smudging can result from improper handling or machine operation.

9. Excessive Solder Paste Volume

A 3D solder paste inspection system effectively measures the actual paste volume, which helps prevent insufficient or excessive solder application.

Conclusion

Addressing solder paste printing defects is critical for ensuring the reliability of SMT processes. By understanding common issues and their root causes, manufacturers can implement effective corrective measures. This proactive approach will enhance overall production quality and improve yield rates, ultimately benefiting both manufacturers and consumers. Focusing on precision in solder paste application can lead to fewer defects and a more successful assembly process.

We can help to simplify and qualify your PTH PCB assembly process. We are also helpful at Through-hole process.

AI Spare parts

SMT AGV Robots

SMT cleaning solutions

solder paste process management