The E-PT440 Solder Paste Mixer is an advanced, user-friendly machine engineered for mixing a variety of materials, including solder paste, glue, slurry, and more. Its innovative features and exceptional performance make it an essential tool for industries that require precise and effective mixing processes.

Specification:

Model: E-PT440

Voltage: AC 220 v

Revolution: 1000/minute

Rotation: 900/minute

Installation dimensions: 440 * 440 * 550 mm

Time delay precision: set data delay error < 0.1% ;repeat delay error < 0.1%; no effect change between AC85-264v voltage

Reset method: power reset

Control methods: electricity latency

Repeat: The time interval is not less than 0.5 s

Output capacity: AC250V 3 A; DC24V 3A (resistance)

Insulation strength: 100 M Ω/ 500 DC

Dielectric strength: 2.5 KV/min

Power supply voltage: DC12V DC24V, -5 ~ + 10% ;AC85-264V AC24V AC12V

Mechanical life: 1﹡ 1000000

Electrical life: 5 ﹡100000

Power consumption: MAX300W

Using the environment temperature: – 23 ℃ to 60 ℃

Using the environment humidity: 35-80% RH

Key Features and Benefits:

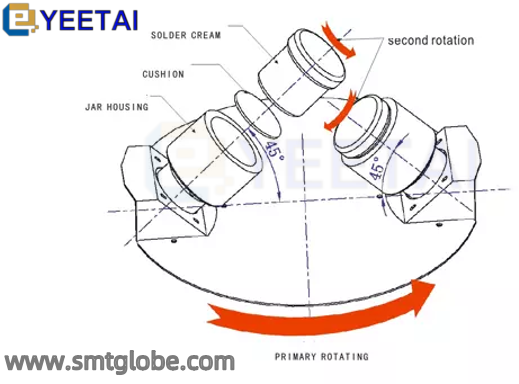

- Principle of Operation:

The E-PT440 utilizes a unique motor revolution and rotation mechanism that provides thorough blending of materials. This ensures a consistent mix every time, crucial for maintaining quality in production. - Rapid Temperature Control:

One of the standout advantages of the E-PT440 is its ability to bring solder paste to the optimal temperature quickly. There’s no need to remove paste from cold storage, allowing for immediate use post-mixing without sacrificing quality. - Time-saving Design:

With the capacity to mix 500g of solder paste and handle two cans simultaneously, the E-PT440 significantly enhances efficiency in your mixing process, saving valuable time in production cycles. - Seamless Mixing Process:

This mixer enables a seamless mixing experience without requiring the solder paste box to be opened, protecting the integrity and purity of materials and minimizing contamination risks. - Optimal Mixing Angle:

By positioning the solder paste at a 45-degree angle and rotating along the axis, the machine prevents adherence to the cover, ensuring a smooth and thorough mixing experience. - Robust Safety Measures:

The E-PT440 is equipped with double safety devices that prioritize user security during operation. This feature gives operators peace of mind while handling the machine. - Advanced Digital Control:

Featuring micro PC digital control, the mixer allows for straightforward operation and precise adjustments to mixing parameters, enhancing usability and control. - Versatile Applicability:

The E-PT440 is suitable for all brands of Tinol and various materials, making it a versatile solution tailored to meet diverse production needs. - Comprehensive Safety Protocols:

The machine incorporates multiple safety protections, further ensuring safe and reliable operation, boosting user confidence in performance.

Conclusion

The E-PT440 Solder Paste Mixer combines cutting-edge design with practical features, delivering high-quality and efficient mixing capabilities for a wide array of materials. With its user-friendly operation, time-saving design, and stringent safety features, it is a valuable asset for any industry focused on achieving optimal mixing results. Elevate your mixing processes with the E-PT440, where precision meets performance.

We also have other machines for solder paste storage management.