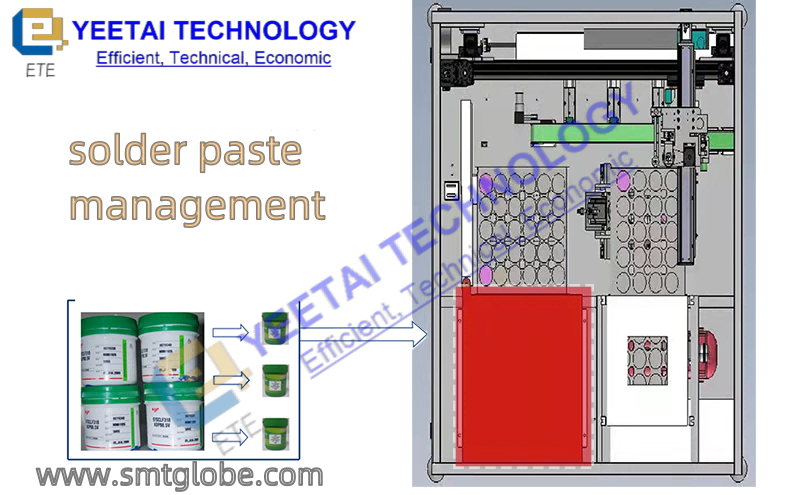

Solder Paste Storage Cabinet: Integrated Solutions for Efficient Solder Paste Management

Are you struggling with solder paste management? Do you want to enhance the traceability of your solder paste processes? Look no further than our Solder Paste Storage Cabinet.

In the fast-paced world of Surface Mount Technology (SMT) manufacturing, effective solder paste management is crucial for maintaining production efficiency and ensuring product quality. Our Solder Paste Storage Cabinet offers a comprehensive solution by integrating essential functions: solder paste storage, temperature control, mixing, and compatibility with Manufacturing Execution Systems (MES). This intelligent system streamlines the solder paste handling process. And it ensures optimal performance in SMT factories.

Specification

| Content | Specification | YTP-300 | YTP-600 | Remark |

| Cold storage | Cold storage capacity | 300 jars | 600 jars | Unlimited category, mixed with multiple varieties. Can be used for tubes. |

| Refrigerating temperature | 1~10℃ | +/-1.0℃ | ||

| Refrigeration method | Drawer layered design | Low loss of air conditioning and more uniform temperature | ||

| Temperature monitoring | Real-time digital display and graph display | Over temperature alarm | ||

| Refrigeration system | Industrial grade compressor | Automatic defrosting protection (anti-icing) | ||

| Temperature Return | Temperature return capacity | 79 jars | 149 jars | Unlimited category |

| Return temperature | 18 ~ 28 ℃ (room temperature) | Wind circulation control | ||

| Return temperature time | 0.1~99h | Can be set per requirement | ||

| Return temperature mode | Automatic/manual reservation/MES online instruction | Support MES work order binding | ||

| Error prevent of return the temperature | Automatically return to the refrigerated area if it is not collected after timeout | Priority for next use | ||

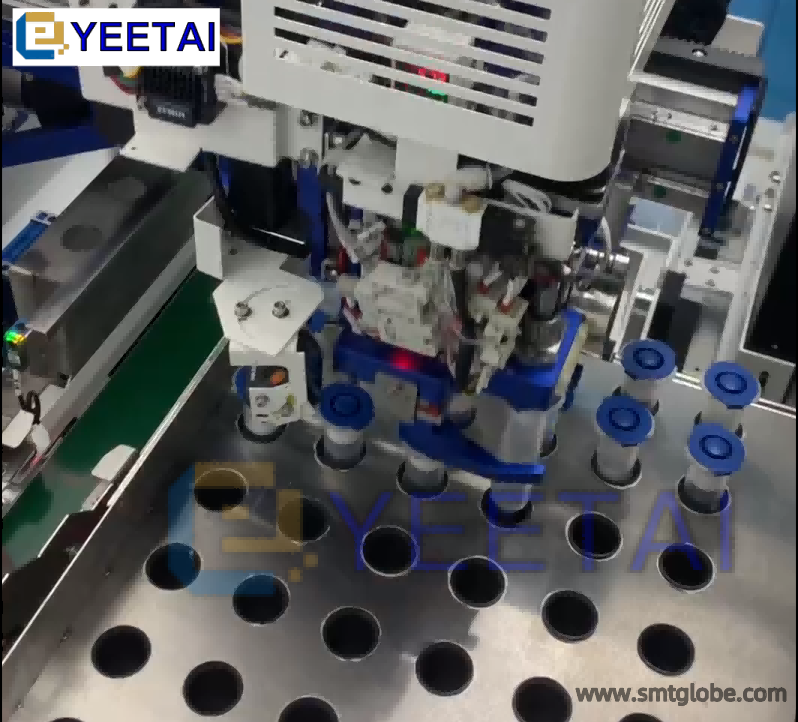

| Solder Paste Mixer | Mixing quantity | 1 or 2 bottles | Automatic weight distribution | |

| Mixing speed | 100-1000 rpm | |||

| Mixing time | 1-10 minutes | |||

| Material input and output | Loading mode | Continuous belt buffer type of loading | ||

| Single feeding quantity | 24 jars | 36 jars | Input and output time<3 seconds/bottle(jar) | |

| Code reading mode | Automatic code reading | Verify records and differentiate by category | ||

| Barcode type | One-dimensional/QR code | Bottle side/top reading code | ||

| Solder paste collection | Permission verification and on-demand collection | More variety, more quantity | ||

| Use up confirmation | Code elimination | Collection timeout warning. Time can be set | ||

| Solder paste back storage | Can be stored twice/three times, and priority use | The number of save backs can be set | ||

| Discharge principle | First In First Out | Loading time/production date | ||

| Machine operation | Permission to operate | Level 4 permission protection | ||

| Permission identification | Fingerprint + IC card + password | |||

| Abnormal alarm mode | Tri-color warning light + beep | |||

| Servo module | Bus-type design + absolute encoder | Stable and easy to maintain | ||

| Control mode | PC+PLC | |||

| Mode of operation | Touch PC operation | |||

| Data and MES | Information traceability | Scan the code for inquiry | Forward/reverse tracing | |

| Data report | Update of real time | Query, export, network share | ||

| Inventory alert | Safety stock alert, impending alert, overdue alert | Parameters can be set | ||

| MES system | MES compatible | |||

| Log | Log storage function | Running status and exceptions can be queried. | ||

| Others | Internal monitoring | Built-in real-time monitoring system | Support video playback | |

| Air supply demand | External air source 0.4-0.65 mpa; Self-provided standby air supply | No steam source. Can work normally during ‘off-work time’ | ||

| Power supply demand | Ac220v/50hz | |||

| Equipment power | 2000w | 2200w | ||

| Equipment weight | 1200kg | 1400kg | ||

| Size of equipment | 1500x1690x1950mm | 1630x2300x1950mm | L x w x h | |

| Optional accessories | UPS power supply | Standby for more than 8 hours | UPS energy-saving protection function | |

Intelligent Solder Paste Storage

The Solder Paste Storage Cabinet features an automated design that simplifies the entire solder paste management process. Key functionalities include:

- Automatic Material Entry Scanning: Streamlines the storage process.

- Efficient Cold Storage: Maintains a precise temperature range of 1 to 10°C.

- Real-time Monitoring: Digital displays and temperature curves allow for effective monitoring of storage conditions. Ensuring various types of solder paste stored together without contamination.

Controlled Temperature Return

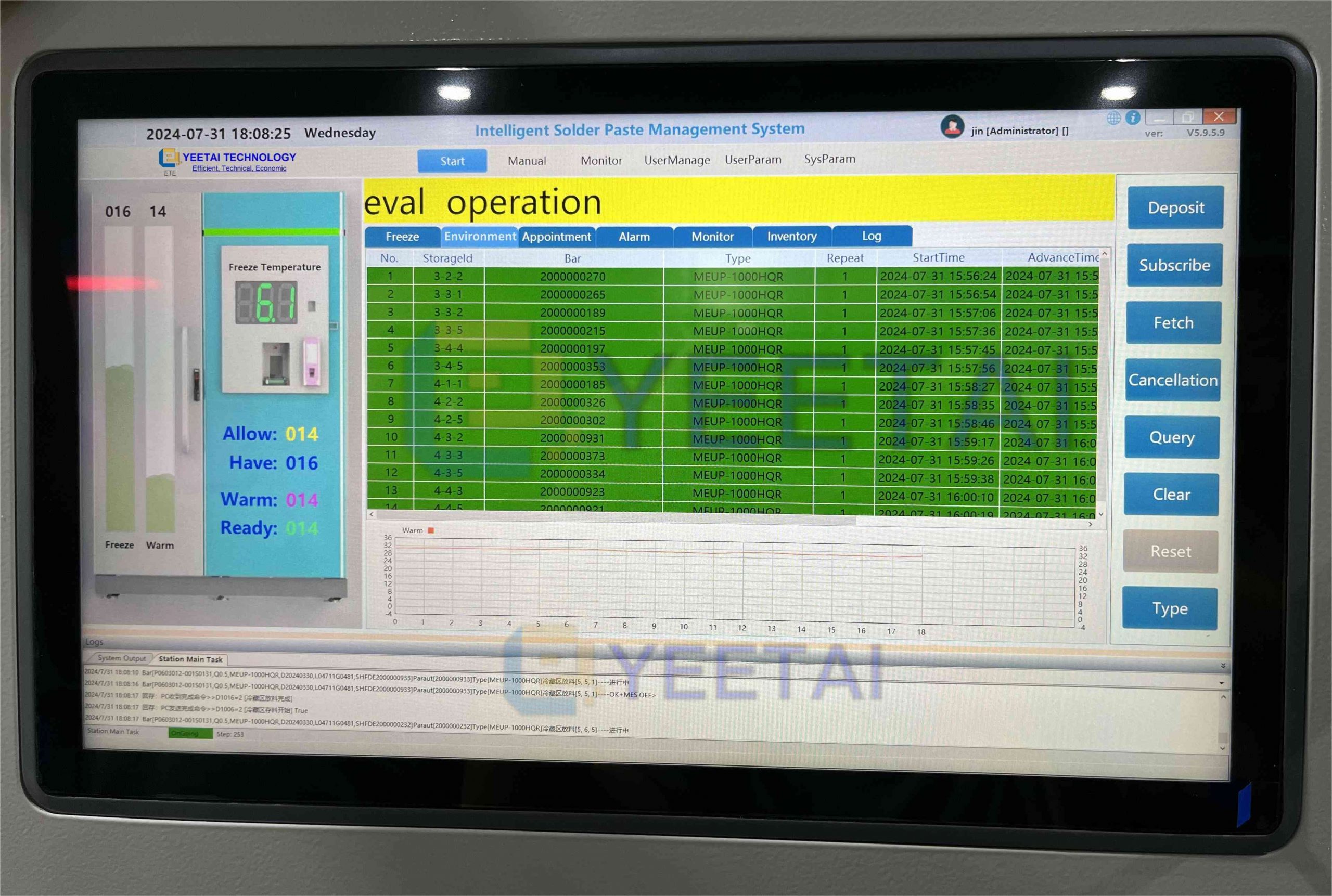

Temperature control is vital for maintaining solder paste quality. The Solder Paste Storage Cabinet allows users to schedule temperature returns based on specific categories and work orders. Users can easily set timing through manual input or MES online reservations, ensuring that solder paste is always at the optimal temperature before use. This feature enhances solder paste performance during the manufacturing process.

Efficient Solder Paste Mixing

Once the solder paste reaches the desired temperature, the cabinet automatically initiates the mixing process. This customizable function allows users to set mixing time and speed parameters according to their specific needs. The cabinet can handle one or two bottles at a time, ensuring thorough mixing for consistent application.

Advanced Dispensing with FIFO Principle

Our Solder Paste Storage Cabinet adheres to the First In, First Out (FIFO) principle during dispensing. This continuous single-bottle design guarantees solder paste used in the order. Minimizing waste and ensuring the freshest solder paste is always in use.

MES Compatibility for Enhanced Data Management

Integration with Manufacturing Execution Systems (MES) is a key feature of the Solder Paste Storage Cabinet. It supports personalized MES interfaces, facilitating real-time data exchange. You can back up and archive all data. It allows for easy access via local and network queries. This compatibility enhances overall production efficiency and provides valuable insights into the solder paste management process.

Traceability and Monitoring

Traceability is a significant advantage of the Solder Paste Storage Cabinet. You can track each bottle/jar of solder paste throughout its life cycle, with forward and backward traceability features. The built-in monitoring system allows for real-time observation of operations and playback of recorded footage, ensuring comprehensive oversight of the solder paste handling process.

Stability and User-Friendly Design

Designed for stability and ease of maintenance, the Solder Paste Storage Cabinet features a bus-type design that separates electrical wiring for independent control. Utilizing an absolute encoder servo module ensures reliable performance. Additionally, the cabinet comes with a self-contained air supply system. Guaranteeing uninterrupted operation even during holidays or when factory air sources are unavailable.

Conclusion

Our Solder Paste Storage Cabinet represents a significant advancement in solder paste management for SMT factories. By integrating solder paste storage, temperature control, mixing, and MES compatibility, it offers a robust solution that enhances efficiency, quality, and traceability. Investing in this intelligent system not only streamlines operations but also ensures your solder paste management meets the demands of modern manufacturing environments.

We also have other machines for solder paste storage management.