The SMT reel tape splicer, model ET-804, revolutionizes material handling processes with its advanced automation features, enhancing efficiency and accuracy in various production environments. By focusing on automation and streamlining manual tasks, this machine offers a range of benefits that optimize workflow and improve overall productivity.

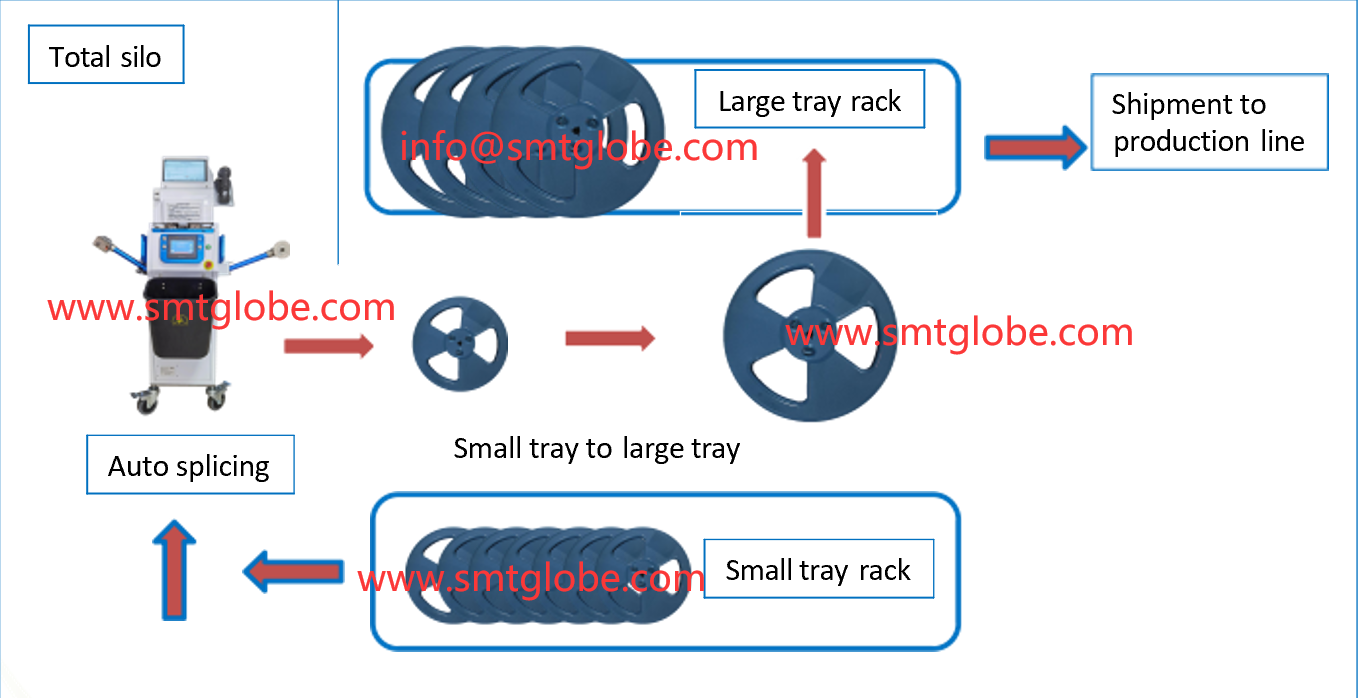

Automatic Material Receiving:

- The SMT reel tape splicer replaces manual material receiving with an automated process, significantly increasing the likelihood of successful transfers and enhancing equipment transfer rates.

Automatic Verification:

- With automatic verification capabilities, manual sampling and measurement are eliminated, ensuring foolproof and efficient operations. This feature enhances accuracy and reduces the risk of errors in material handling.

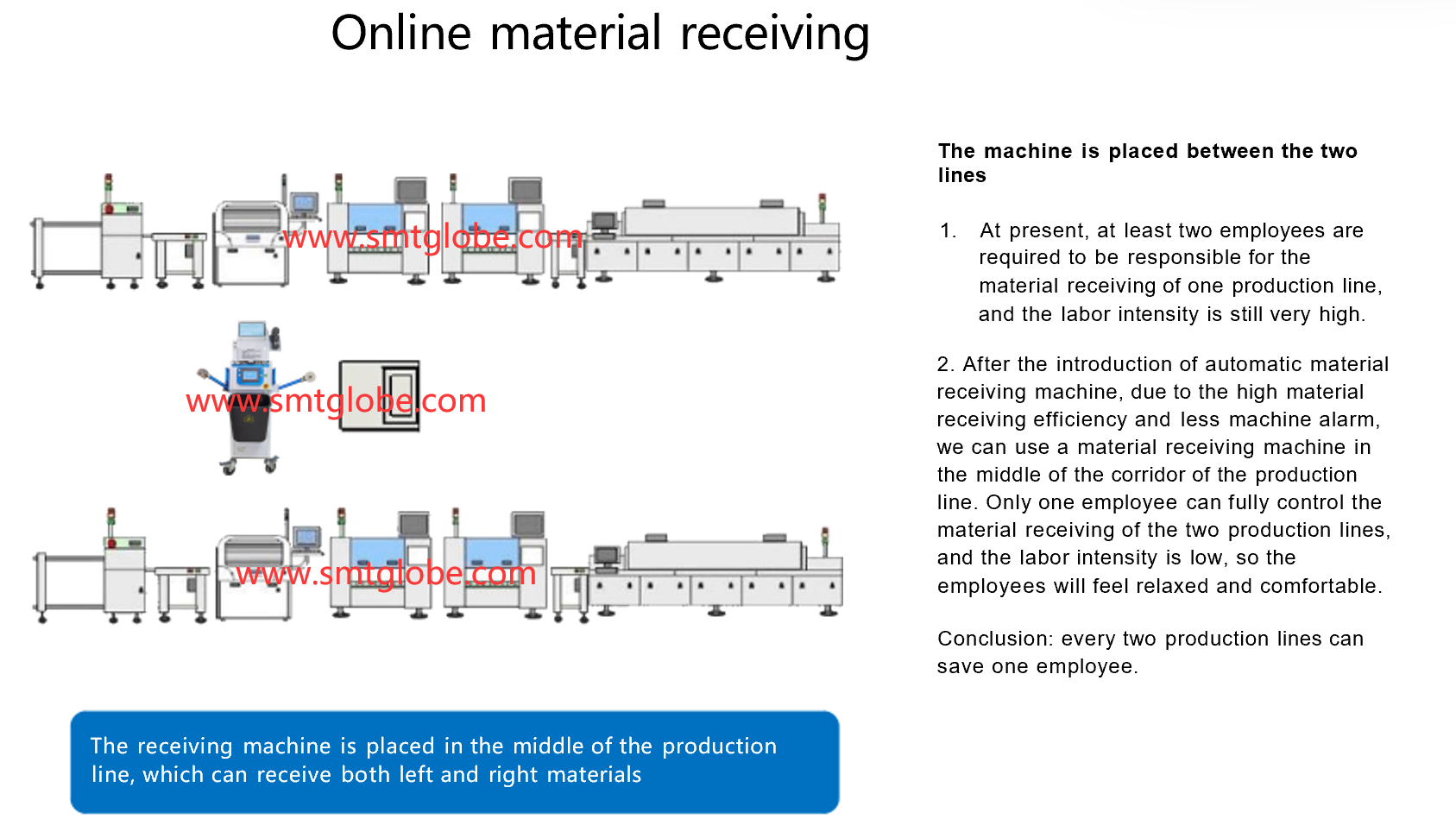

Labor Intensity Reduction:

- By reducing the labor intensity of employees and streamlining production processes, the machine boosts work efficiency and productivity. This leads to improved operational efficiency and a more streamlined workflow.

Management Cost Reduction:

- The machine helps in reducing management costs and staff turnover by increasing automation and decreasing reliance on manual labor. It ensures a unified material receiving status, minimizing discrepancies and enhancing operational consistency.

Advanced Material Support:

- The SMT reel tape splicer supports various material tapes, automatically adjusting the width to accommodate different materials. It can detect empty materials and handle components of at least 01005 specification, ensuring versatility and adaptability in material handling.

Automated Measurement and Identification:

- Offering automated measurement and identification capabilities for components of various specifications, the machine ensures accuracy and consistency in material handling processes.

Integration with MES System:

- By connecting seamlessly with customer MES systems, the machine closes the system loop to prevent wrong material handling. It can be utilized in incoming inspection, warehouse operations, and other stations, ensuring operational alignment and data consistency.

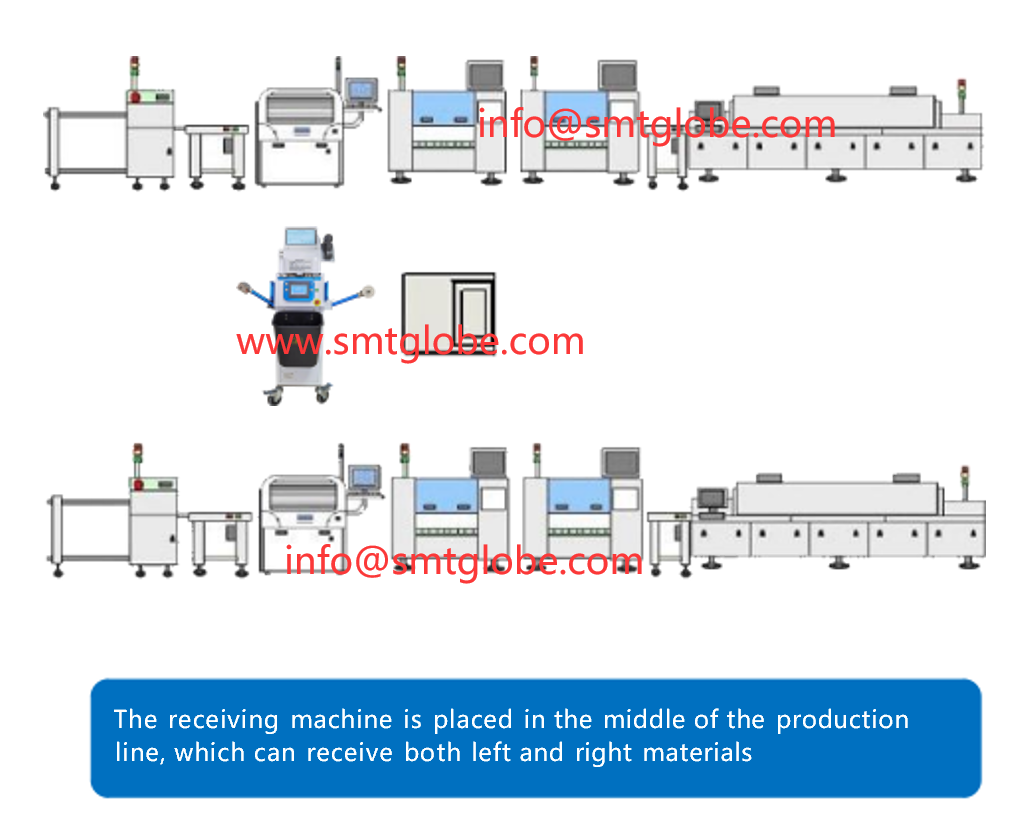

Time and Manpower Savings:

- Whether used for online material receiving or small inventory consolidation in warehouses, the automatic material receiving function of the SMT Reel Tape Splicer saves significant time and manpower, optimizing operational efficiency and resource utilization.

In conclusion, the SMT Reel Tape Splicer, model ET-804, stands out as a cutting-edge solution that enhances material handling processes through automation, accuracy, and efficiency. Its advanced features and capabilities make it a valuable asset in modern production environments, offering streamlined operations, improved productivity, and enhanced quality control.

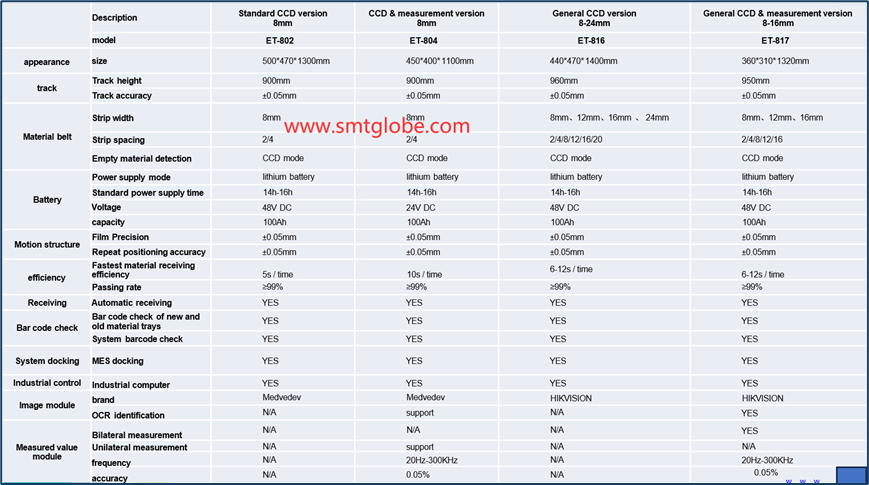

Specification

Overview of the SMT Reel Tape Splicer ET-804

The Surface-Mount Technology (SMT) Reel Tape Splicer ET-804 is an advanced piece of equipment designed to enhance the efficiency and accuracy of electronic manufacturing processes. This device boasts a versatile range of functions catered to handling various SMT material tapes and ensuring superior operational control. Here’s a deeper look at its key features:

- Multi-Material Support: The ET-804 is compatible with a variety of material tapes including paper, black, and transparent tape, making it suitable for diverse manufacturing requirements.

- Automatic Width Adjustment: This machine automatically adjusts tape width, supporting materials with a belt width of up to 8mm, which streamlines the splicing process.

- Precision Splicing Configuration: It provides precision in splicing with a standard 2/4 mm string alignment.

- Thickness Compatibility: The ET-804 can handle thickness strips ranging from 0.1mm to 1.5mm, thus accommodating a wide spectrum of tape sizes.

- Material Detection: It is equipped with sensors to support material detection capabilities, efficiently managing up to 01005 component sizes.

- Automated Quality Checks: The machine effectively checks resistive values, capacitance, and voltage, along with conducting a sensory evaluation for screen printing errors on conductive materials.

- Error Proofing through Scanning: It incorporates wireless scanning for barcode detection which aids in code checking and reduces error margins significantly.

- MES Integration: Interface with manufacturing execution systems (MES) enhances data transparency and operational efficiency across the manufacturing floor.

- User-Friendly Interface: Designed with simplicity in mind, the machine features a simple yet effective interface to facilitate ease of operation.

- Access to Online Features: An online machine-to-machine (M2M) feature enhances its capabilities and supports better management of the manufacturing process.

In summary, the SMT Reel Tape Splicer ET-804 is engineered to meet the challenges of modern electronic manufacturing, combining high-precision technology with user-friendly features to deliver outstanding performance and reliability. Its ability to support multiple types of materials and integration with advanced system management tools makes it an indispensable asset in the high-speed world of electronics production.