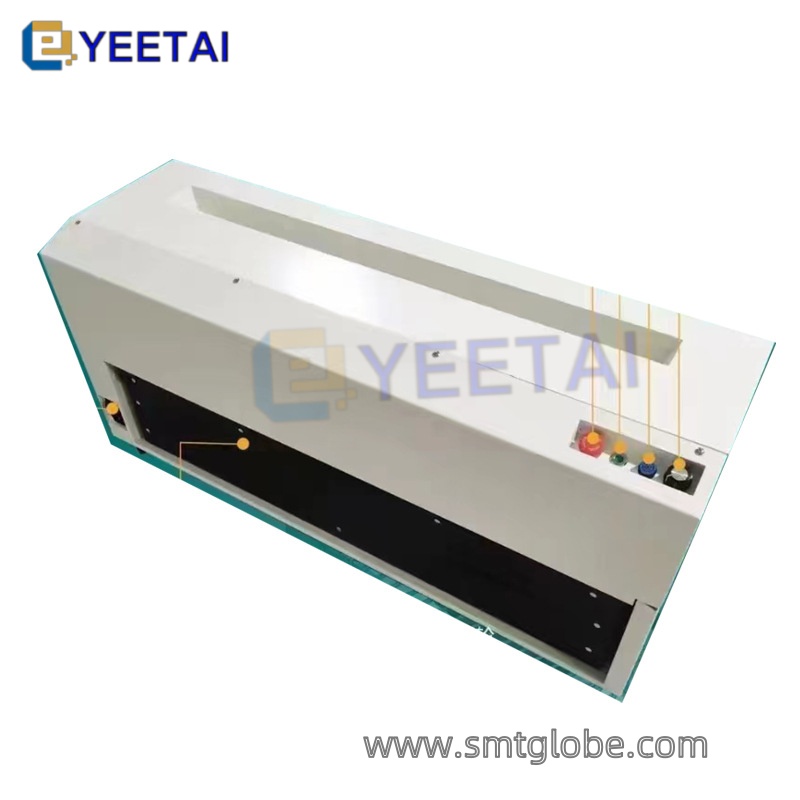

SMT Reel Tape Scrap Collector: Efficient Waste Management for SMT Production

The SMT Reel Tape Scrap Collector, or SMT Reel Tape Scrap Cutting Machine, is an innovative solution. It is for cutting SMT material tapes. Specifically addressing the need for efficient recycling of waste material at pick-and-place machine stations. In traditional setups, pick-and-place machines has no built-in recycling capabilities. Thus this requires manual disposal of waste tape using scissors, which can be both inefficient and time-consuming. Our SMT tape cutting and recycling machine completely automates this process. And it allows for the seamless cutting of both tape and film.

Key Features of the SMT Reel Tape Scrap Collector/ SMT Reel Tape Scrap Cutting Machine

- Versatile Cutting Capability

This cutting machine is suitable for various SMT tape types. Effortlessly cutting materials ranging from 0.05mm thin film to 1.5mm. - Compact and User-Friendly Design

The equipment boasts an aesthetically pleasing appearance and occupies minimal space. It is designed for easy operation and storage, with specific dimensions customizable to fit your pick-and-place machine models. - Durable Blade Material

The blades are from imported SKD-11 steel. And our blades come with a one-year warranty without the need for sharpening. Ensuring long-lasting performance.

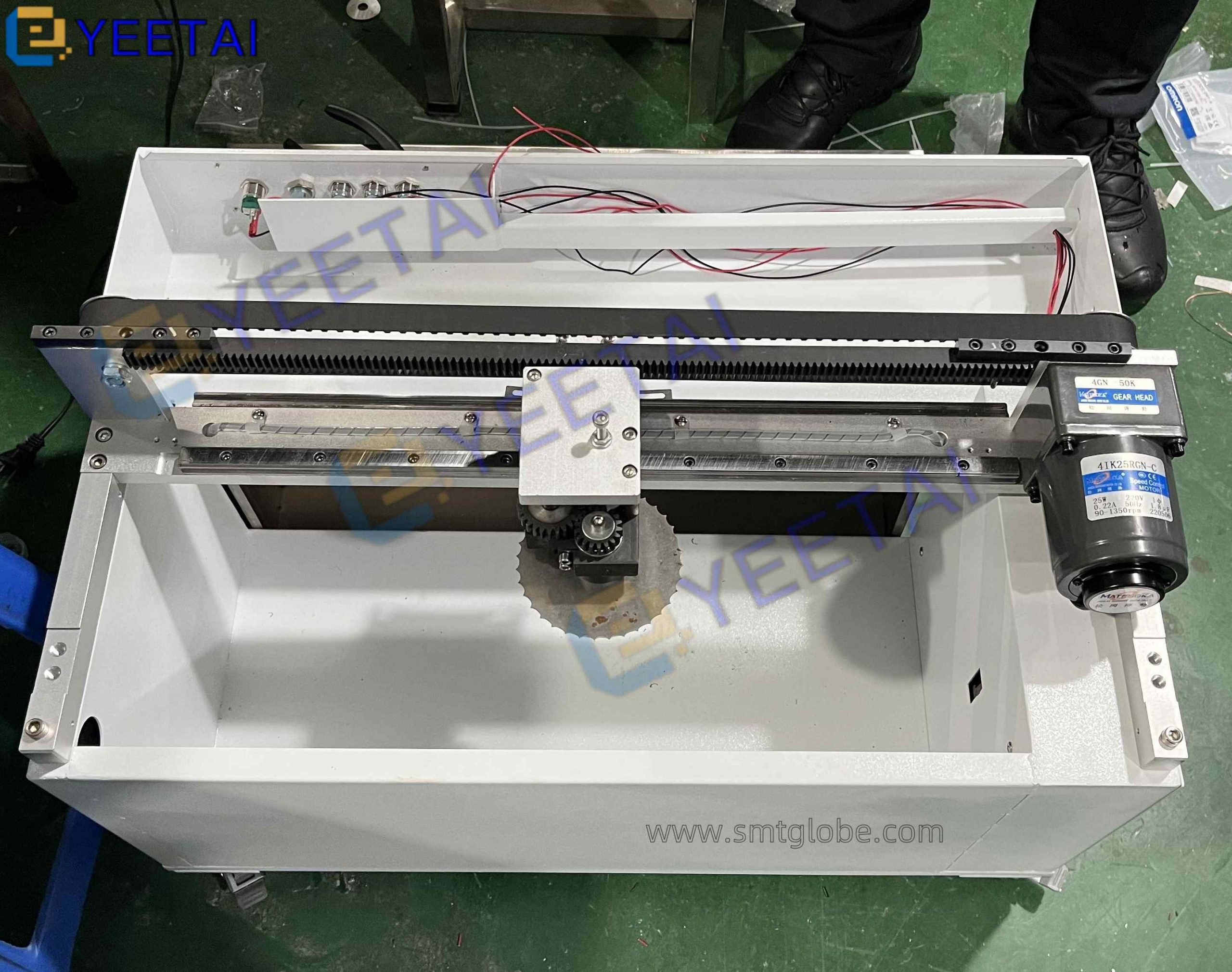

Advanced Cutting Mechanism

Our rolling cutting mechanism employs the tension of eight springs at the base of the toothed blade. This ensures optimal contact between the blade’s edge and the straight knife point during cutting. This innovative design significantly reduces the rapid wear commonly seen in conventional cutting machines. Our tape cutting machine includes a two-year warranty (including the blade). With the straight knife being usable on all four sides and the toothed blade capable of multiple sharpenings. This design effectively resolves frequent jamming issues associated with traditional tape cutters.

Intelligent Control System

Equipped with microcomputer intelligent control, users can easily set cutting time and length. With a simple one-button start/stop feature for enhanced user convenience.

Safety Features

The waste recovery area includes a safety sensor. The sensor automatically stops the machine when the waste tray is removed. Therefore, it prevents any risk of accidents while ensuring that all cut scraps fall into the recovery box.

Limit Switch Protection

The cutting stroke is fitted with limit switches at both ends. If the stroke exceeds the limit, the entire machine will shut down. This prevents potential damage and short-circuiting caused by the motor continuing to operate if the photoelectric switch fails.

Specification

| Overall Dimension | LxWxH=960x295x520mm |

| Transmission mode | Gear assembly |

| Feeding range | LxW=815x60mm |

| Weight | 35KG |

| Power supply | AC220V, 50-60HZ |

| Control program | PLC |

| Cutting method | Circular Knife Traveling Cutting |

| Drive type | Motor + Timing Belt |

| Cutting Range | LxW=745x25mm |

| Cutting speed | 4m/min |

| Safety | 1 A |

| Bin sensing | Photoinduction |

Conclusion

Our SMT Reel Tape Scrap Collector not only enhances operational efficiency but also contributes to a safer and cleaner working environment. By automating the tape cutting and recycling process, companies can improve their 5S management capabilities. As evidenced by positive client feedback during facility visits, especially regarding the pick-and-place machine stations.

For more information about our SMT tape cutting solutions or to request a quote, please contact us today!