Optimize Your SMT Workshop with Our Advanced SMT Reel Tape Cutter

Are you struggling with excessive waste from carrier tape in your SMT (Surface Mount Technology) workshop? Is your production line cluttered and inefficient? Our SMT Reel Tape Cutter is designed to transform your SMT workspace, streamlining waste management and enhancing operational efficiency.

Common Challenges in SMT Production

- Inefficient Waste Management: Manual cutting and disposal of carrier tape can create a mess and disorganization.

- Risk of Damage: Uncut carrier tape can pose risks to machines and components during production.

- Cleanliness Issues: Excess clutter may lead to lost customer orders and tarnished reputations.

Our automatic intelligent tape cutter addresses these challenges effectively. By eliminating manual management of waste carrier tape, we help you maintain a clean and organized SMT workshop, enhancing productivity and safety.

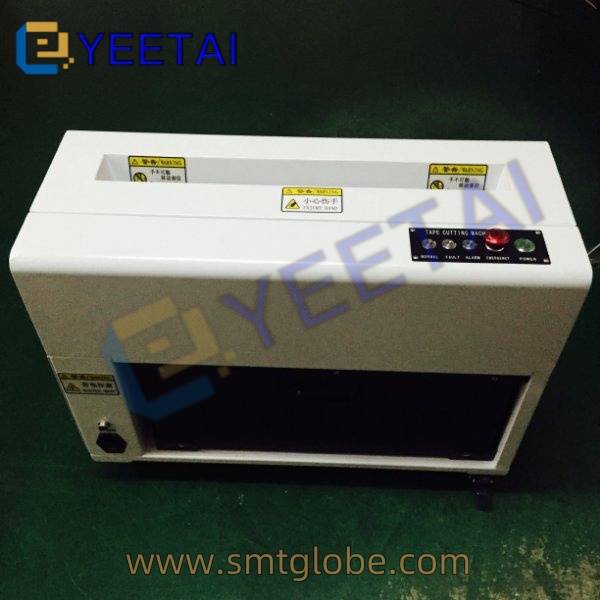

Key Features of Our SMT Reel Tape Cutter

1. Intelligent Microcomputer Control

Experience precise cutting control with our advanced microcontroller, featuring customizable cutting modes such as delay cutting and sensor activation.

2. Versatile Cutting Capability

Our cutting machine accommodates various tape types, from 0.04mm thin film to 1.5mm thick tape, ensuring versatility and efficiency in your production line.

3. Stable Performance

With high-quality imported high-speed steel blades, the cutter operates on a scissor-like principle. This design guarantees stable and durable performance, suitable for an effective cutting width of 680mm.

4. Compact and Mobile Design

Measuring just (L) 900 x (W) 260 x (H) 430 mm and weighing only 45 KG, our cutter is easy to move and store, saving valuable floor space.

5. Safety Features

- Anti-Static Material Box: The stainless steel frame enhances durability while maintaining an aesthetic appearance.

- Status Alarm System: The cutter will not operate if the material box is empty, ensuring safety during operation.

- Motor Jam Protection: If a jam occurs, the system triggers an alarm and stops power, preventing overheating and damage.

6. Standby and Error-Proofing Functions

The machine automatically enters standby mode if no boards are fed for an extended period. Additionally, an optional barcode scanner can be integrated for error-proofing during material changes.

7. Customizable Cutting Parameters

Adjust the stopping times at cutting points A and B to reduce blade wear and precisely control the length of the cut tape.

8. Advanced A+ Version

Our A+ version features a dual-direction transmission mechanism that solves issues related to belt length and motor transmission, ensuring consistent cutting force and extending the life of the belt.

Technical Specifications

- Operating Temperature and Humidity: 10±40°C, 20%-90% RH

- Compatible Tape Materials:

- 8M paper tape

- 8-44M plastic tape

- Optional: vinyl soft tape

- Cutting Cycle: 9 seconds (excluding delays)

- Effective Cutting Width: 680mm (customizable)

- Dimensions: (L) 900 x (W) 260 x (H) 430 mm; customizable to fit your pick-and-place machine

- Weight: 45 KG

- Power Consumption: 0.05 KW

Main Consumable Parts

- Main Blade (imported high-speed steel): Lifespan: 1-2 years

- Secondary Blade (imported high-speed steel): Lifespan: 1-2 years

- Drive Belt: Lifespan: 1-2 years

Why Choose Our SMT Reel Tape Cutter?

Investing in our SMT Reel Tape Cutter not only streamlines your waste management but also enhances safety, efficiency, and organization in your production environment. Don’t let carrier tape become a burden—choose our innovative solution to create a cleaner and more efficient SMT workshop.

For more information or to request a demo, contact us today!