SMT Nozzle Cleaning Machine: Efficient Cleaning for Optimal Performance

Our SMT Nozzle Cleaning Machine is a state-of-the-art solution for the efficient clenaing. It fully automated cleaning of up to 24 nozzles at the same time. Utilizing advanced multi-nozzle spray cleaning technology, this machine is specially designed to remove solder paste and other contaminants effectively. With dedicated trays compatible with various SMT machine nozzles, the ET-24NZ ensures reliable performance and compatibility across different models. After the cleaning process, a built-in compressed air system guarantees thorough drying. Thus it is a convenient investment for maintaining your SMT equipment.

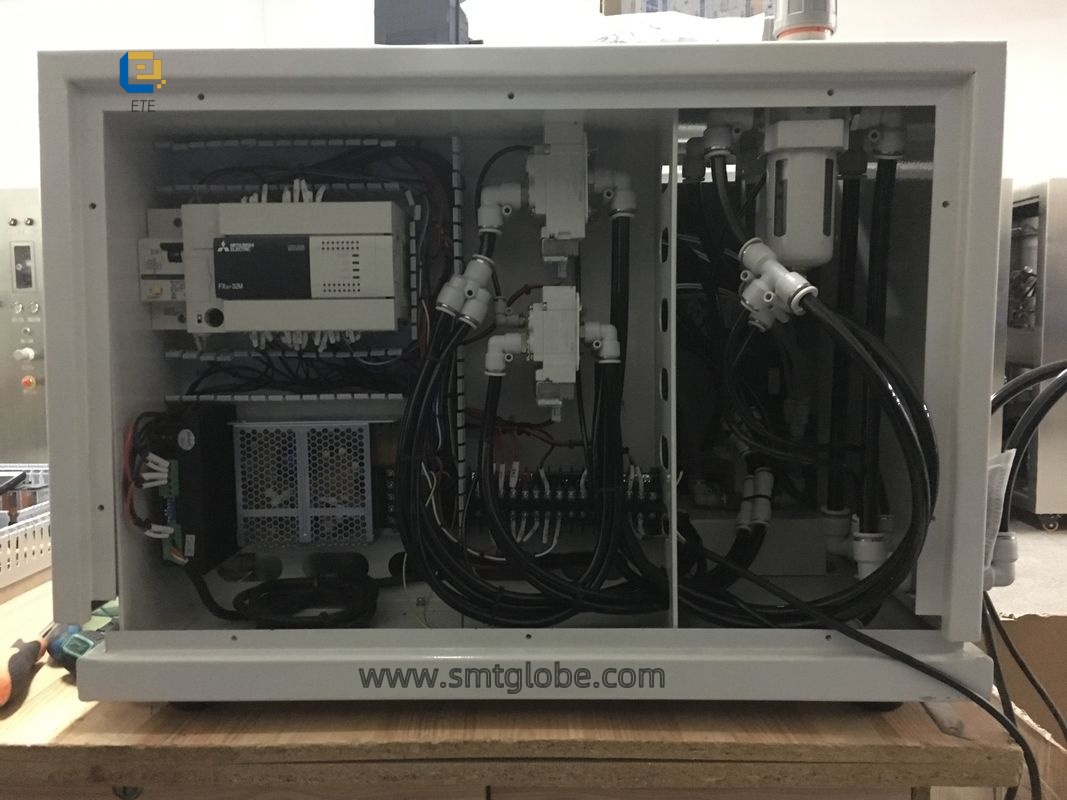

Key Features of the ET-24NZ SMT Nozzle Cleaning Machine

- High Efficiency: The ET-24NZ cleans up to 24 nozzles at once, significantly reducing cleaning times compared to traditional manual methods.

- Advanced Cleaning Technology: Employing ultrasonic water mist supersonic jet cleaning technology. The machine effectively removes dirt and impurities that are difficult to tackle with conventional ultrasonic cleaning. This minimizes the risk of component displacement during production.

- Comprehensive Cleaning: The nozzle cleaning machine excels at cleaning even the smallest nozzle apertures. Cleaning rate of over 99%. This thorough approach enhances the lifespan of the nozzles and ensures optimal performance.

- Protective Design: A specialized cover plate safeguards the surface coatings and reflector plates of the nozzles. Maintaining their integrity and performance over time.

- Eco-Friendly Operation: Designed to operate with pure or deionized water. The ET-24NZ eliminates the need for harsh cleaning agents. Promoting an environmentally friendly cleaning process.

- User-Friendly Interface: The machine is easy to operate and suitable for a variety of SMT pick-and-place machine nozzles. It is a convenient and efficient maintenance solution.

- Reliable Performance: The advanced cleaning technology and user-friendly design make this machine an asset for enhancing production efficiency. While ensuring the longevity of all SMT equipment.

Specification

| Name | ET-24NZ SMT Nozzle Cleaning Machine |

| Air Source | 0.5~0.7Mpa |

| Power source | AC220V,1A |

| Cleaning fluid | Pure water or DI water |

| Cleaning time | 3~6min |

| Blow-drying time | 2~3min |

| Spraying pressure | ≤0.55Mpa |

| Cleaning fluid consumption | ≤150cc/hour |

| Cleaning nozzle range | Minimum 01005~Maximum inner diameter ¢2.0mm |

| Fixture specifications | Small suction nozzle 24 holes / large suction nozzle 12 holes |

| Machine size | l665*w555*h475(mm) |

| Machine weight | 30KG |

Important Safety and Operation Guidelines- User Manual

Please read our user manual thoroughly before operating this equipment.

- Installation: Avoid installing the machine near sources of electromagnetic interference.

- Maintenance: Keep the user manual for reference to maintain the equipment according to specifications.

- Software and Hardware Settings: Do not modify software or hardware settings inside the control box. The connected computer is designated solely for control purposes.

- Electrical Requirements: Ensure compliance with IEC61000-3-4 and EN61000-3-11 standards for power system connection.

Packing List

The packing carton includes the following accessories (in addition to the main unit). If any items are missing, please contact us.

- Nozzle Tray (customized per the customer’s specification)

- Spare Parts and Tools (as per customer requirements)

- User Manual:1 copy- Special Requirements: Refer to the purchasing contract for any additional requirements.

Conclusion

Investing in the ET-24NZ SMT Nozzle Cleaning Machine is a smart choice for any facility. If you aim to enhance production efficiency and maintain the reliability of their SMT processes. With its innovative cleaning technology, user-friendly design, and eco-friendly operation. The ET-24NZ is designed to meet the demanding needs of modern manufacturing environments.

For more information or to place an order, contact us today!