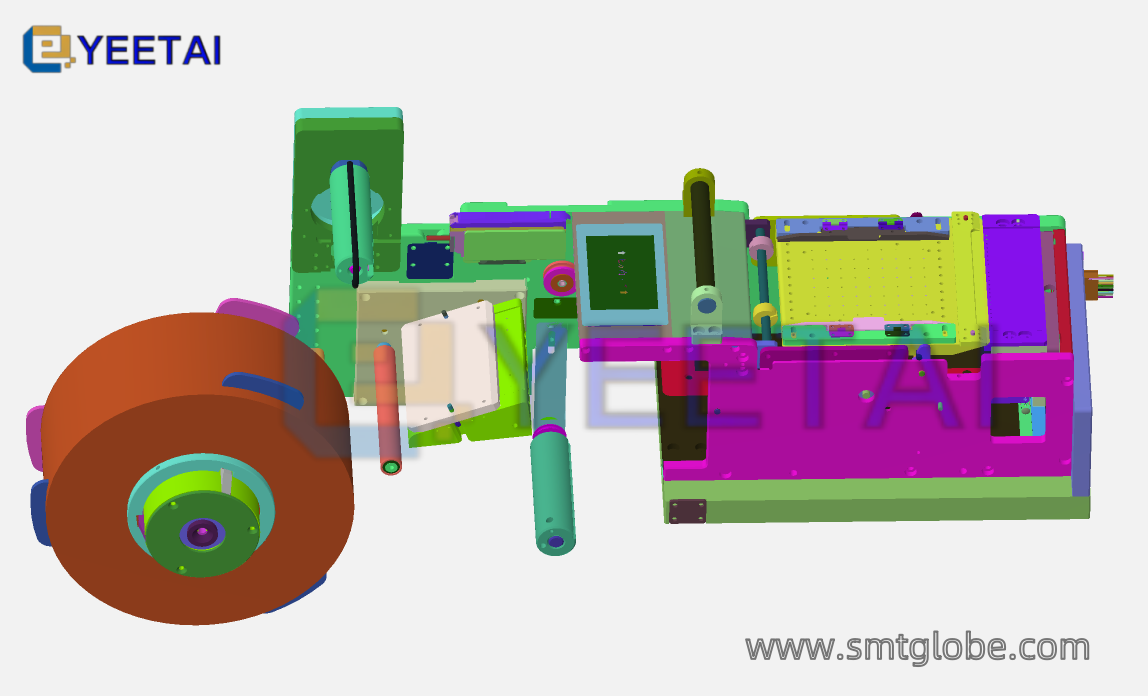

Compact SMT Label Feeder for Enhanced Production Efficiency

Our SMT Label Feeder is an innovative, compact, and cost-effective solution. It is designed for automated label feeding in surface mount technology (SMT) environments. It integrates effortlessly into existing SMT production lines and significantly improves traceability by using barcodes or QR codes.

Functions of SMT Label Feeder:

- Improved Traceability

- The feeder dispenses labels with QR code information, ensuring accurate attachment to PCB boards during assembly. This functionality supports Manufacturing Execution Systems (MES) for real-time SMT production management.

- Versatile Material Handling

- Our feeder accommodates a variety of materials. It handles not only labels but also roll-type supplies such as foam pads, double-sided adhesive tape, protective films, conductive adhesives, and more. It enhances high-speed, high-precision automated production lines, effectively replacing manual labor.

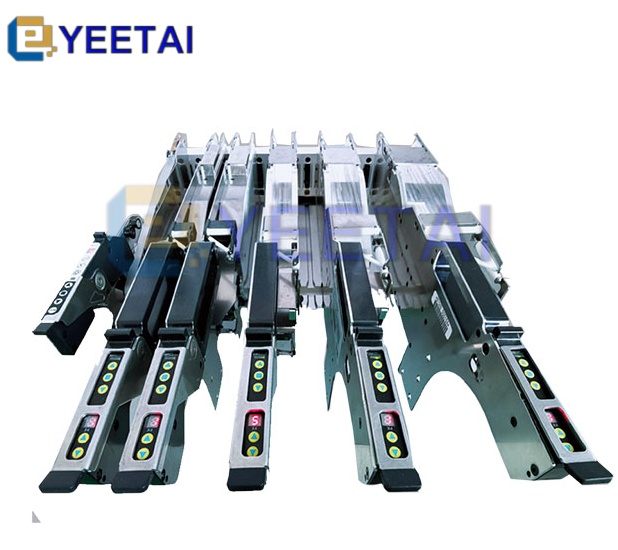

- Wide Machine Compatibility

- Our feeder can perfectly work with leading pick-and-place machine brands including Fuji, Juki, Panasonic, Yamaha, Samsung, and Siemens etc. It allows for seamless collaboration with robotic arms and other automation systems, streamlining your production processes.

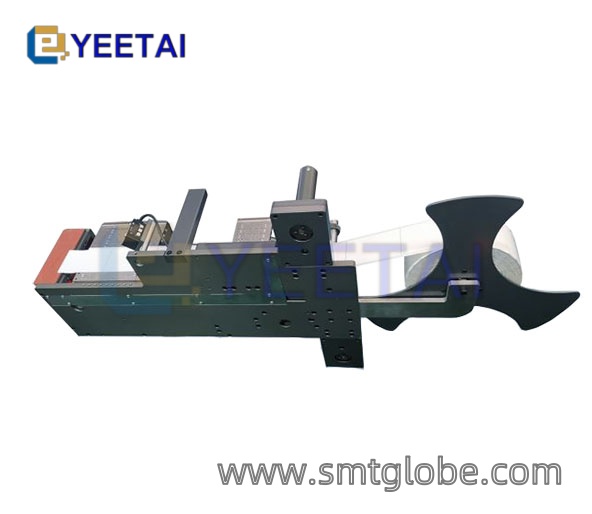

Features of SMT Label Feeder

- Accurate Label Delivery: Delivers labels to precise positions for easy recognition and pick-up by machines or robotic arms.

- Flexible Feeding System: Ensures that labels remain undamaged throughout the feeding process.

- Compact Design: Our feeder’s smaller footprint saves valuable space on feeder racks.

- Adaptability: Capable of accommodating various label sizes and specifications.

- Seamless Integration: Integrates with placement machines and supports MES for enhanced real-time management and production efficiency.

Specifications of SMT Label Feeder

| Model | SMT Label Feeder | ETE-LF01 |

| Dimensions | length x width x height | 650x165x320mm |

| weight | 7.5Kg | |

| Applicable materials | Label backing paper width | Compatible with bottom paper less than 60mm/80mm/100mm |

| Label backing paper thickness | 0.05mm-0.08mm | |

| Label backing paper material | PET plastic film or paper tape release paper | |

| Supported material | Coil packaging materials such as paper labels, protective films, foam, double-sided adhesive tape, conductive adhesive or copper foil and steel sheet | |

| Material(label) size | min>3mm, MAX<backing paper width | |

| Inner diameter of label reel holder | Standard 3-inch core, other specifications can be customized | |

| Material thickness | Customized on request | |

| Maximum load of label reel holder | <3Kg | |

| Structural part | Feeding method | Tape peel-off type |

| Receiving platform | High-density foamed cotton or polymer anti-sticking material | |

| Fiber Channel | Standard configuration “1 out of 1” to “1 out of 12” optional | |

| amplifier | Standard 1 set of independent amplifiers | |

| Material positioning method | Optical fiber sensing + software compensation | |

| Feeding method | Straight through feeding | |

| a fixed way | Positioning key + pressing block, supporting other fixed structures | |

| Cover film method | Support upper independent film extension | |

| Ending paper method | The bottom belt conveys the bottom paper as standard, and supports an independent motor for the bottom paper | |

| Backing paper tension adjustment | Standard discharge wheel mechanical tension, support independent motor independent discharge components | |

| The way of opening and closing the shaft of the hanging tray | Standard claw tensioning structure supports the tensioning of the air shaft | |

| Stripping knife size | Standard 0.3mm, can be customized according to the material | |

| Electrical part | Operating Voltage | 24V |

| Average Current/Peak Current | 1.5A/3A | |

| working pressure | 0.4-0.6Mpa | |

| Operation method | key operation | |

| Host computer connection | 8 core ø16mm aviation plug | |

| communication method | Support IO communication or self-control without communication | |

| software control | Based on ARM (STC32) | |

| drive mode | stepper motor | |

| Motor type | Type 42 | |

| motor speed | 600 rpm | |

| Feeding part | single feeding quantity | Single row and multiple columns, support multi-column extension |

| speed gear | Four gears adjustable | |

| Feeding position adjustment | Limit adjustment in X direction + software adjustment in Y direction + mechanical adjustment in Z direction | |

| Feeding accuracy | X direction ±0.2mm, Y direction ±0.2mm | |

| Throw rate | <0.5% | |

| Test record | Feed test | Achieve 500 times of continuous feeding without exception |

| Aging test | Continuous operation for 48 hours without exception | |

| service life | 5 years service life |

Conclusion

In conclusion, our SMT Label Feeder is an essential tool for modern PCB assembly. By enhancing traceability, supporting diverse materials, and providing versatile machine compatibility, it ensures an efficient and accurate manufacturing process. Upgrade your SMT production line today for streamlined operations and improved productivity.

If you have materials with special package and you want to save cost, feel free to contact us. Or find more feeders below.

If you need instructions on more feeders,kindly visit our website below. They may help you.

Usage and Maintenance of Fuji SMT Machine Feeders

Comprehensive Guide to JUKI Pick-and-Place Machines: Models and Operational Considerations

Maintenance and Care of SMT Feeders

Proper Loading Procedure for SMT Feeders in the SMT Industry