Customize Your SMT ESD PCB Trolley

Contact us to customize a suitable SMT ESD PCB trolley for your SMT factory! If you have special requirements, we are the right manufacturer for you.

Factory Direct Sales

We offer factory direct sales with a quality assurance guarantee. Our trolleys are made using custom processing to meet your specific needs.

SMT ESD PCB Trolley Advantages

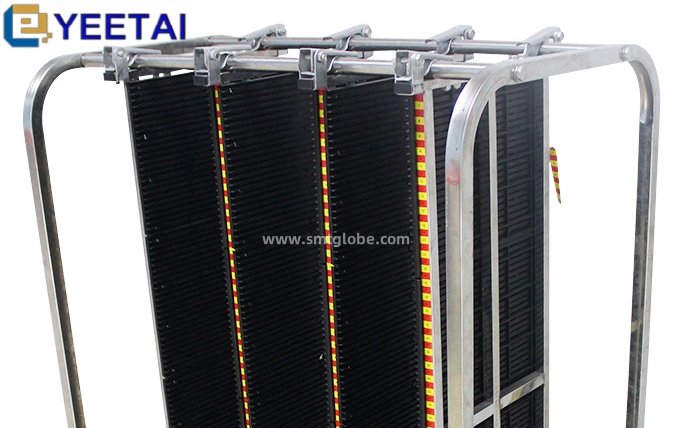

- Convenient and Attractive: Our trolleys are not only functional but also look good.

- Large Storage Capacity: You can store many PCBs efficiently.

- High-Quality Materials: We use premium stainless steel. Our skilled welders ensure high-quality craftsmanship.

- Adjustable Design: The trolley features an adjustable distance with a snap fastener design. The stainless steel frame is rust-resistant and reinforced.

- Trusted Manufacturer: We carefully select materials and guarantee quality. We never cut corners.

Custom Options

We can customize the specifications and sizes of your trolley. This includes surface assembly technology carts and material turnover carts. Tell us your needs, and we will make it happen!

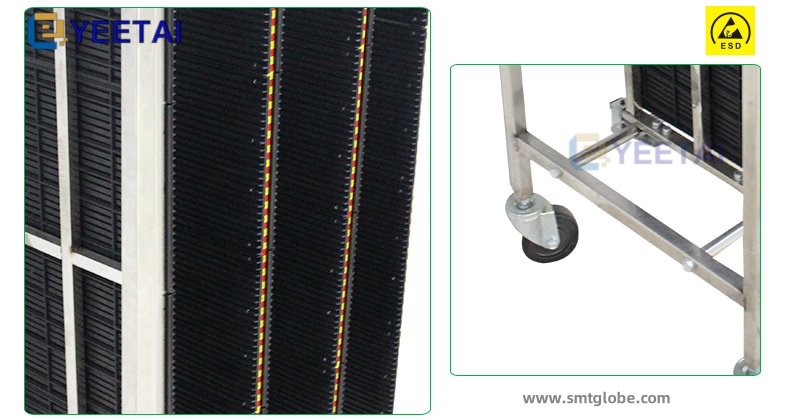

SMT ESD PCB Trolley Panels

The slot panels come in two types: side panels and middle panels.

- Side Panel: This is a single-sided slot board.

- Middle Panel: This is a double-sided slot board. Each side has ten small panels, and each panel contains ten slots.

PCB Insertion Direction

The PCBs insert horizontally. This design allows for easy access and organization.

Improved Quick Clamps

The upper and lower ends of the slot panels have improved quick clamps. This makes them easier to use and adjust.

Swivel Wheels for Easy Mobility

We equip our trolley with four-inch conductive swivel wheels. Two of these wheels also have brakes. This design ensures the trolley moves smoothly while providing stability.

Grounding Chain Installation

A metal grounding chain is installed at the bottom of the trolley. If dirt affects the static discharge of the wheels, the static can still be released through the grounding chain. This keeps your PCBs safe from static damage.

Conclusion

In conclusion, our SMT ESD PCB trolleys are perfect for your factory. They are customizable, durable, and designed to meet your needs. Contact us today to get started on customizing your trolley!

Specification

| Overall Size (L*W*H) mm | Slot Length (mm) | PCB Storage Qty |

| 900*550*1300 | 350mm | 200pcs |

| 300pcs | ||

| 400pcs | ||

| 500pcs | ||

| 600pcs | ||

| 900*600*1280 | 460mm | 200pcs |

| 300pcs | ||

| 400pcs | ||

| 500pcs | ||

| 600pcs | ||

| 900*650*1280 | 530mm | 200pcs |

| 300pcs | ||

| 400pcs | ||

| 500pcs | ||

| 600pcs | ||

| 900*700*1280 | 630mm | 200pcs |

| 300pcs | ||

| 400pcs | ||

| 500pcs | ||

| 600pcs |