Are you searching for a proper SMT ESD magazine rack for your PCB storage? You’ve come to the right place. We are an experienced ESD consumables manufacturer with over 16 years in the industry. Our magazine racks help you organize your PCBs quickly and easily.

Quality Materials for Best Performance

Our SMT ESD magazine rack is made of high-quality, anti-static plastic. We use a special injection-molding process for the frame, ensuring accuracy in size. Thus, this design allows for smooth adjustments without jamming, making it easier to work with your PCBs.

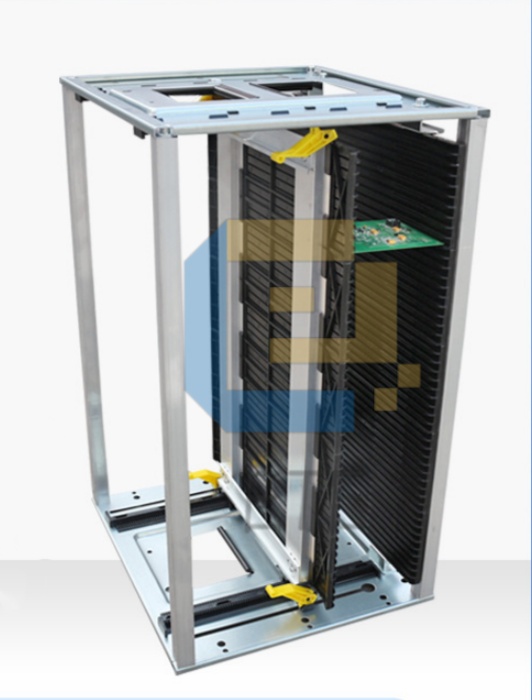

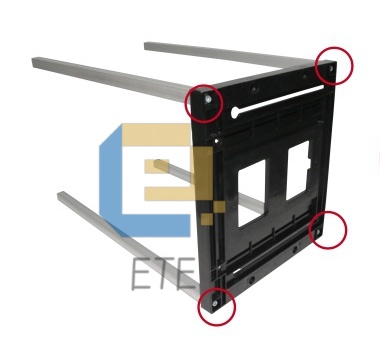

Structure of the SMT ESD Magazine Rack

The SMT ESD magazine rack has three main parts:

- Top and bottom panel

- Non-movable Side Panel

- Adjustable Side Panel

- Aluminum Alloy Vertical Columns

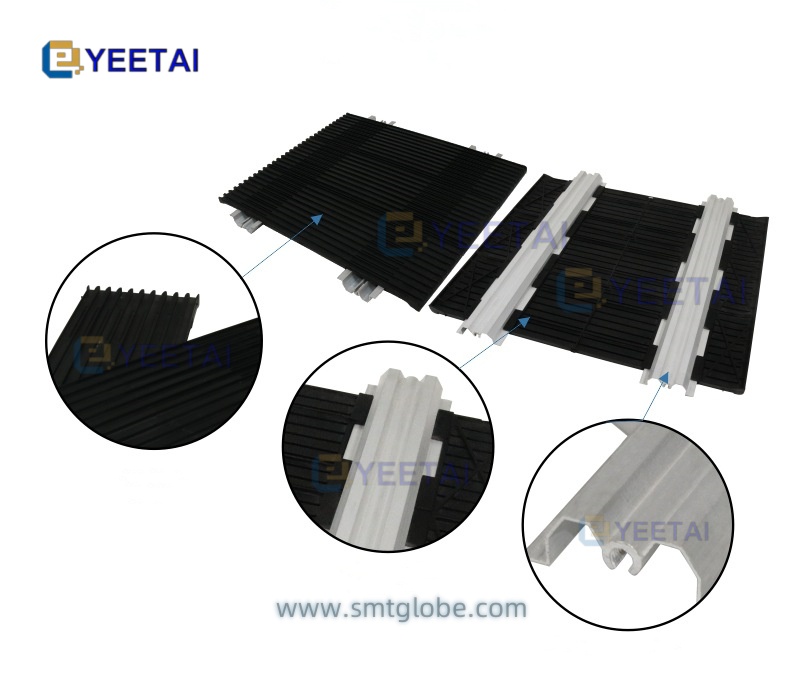

Top and bottom panel

Made from high-quality anti-static plastic, with injection-molded rails to ensure dimensional accuracy, allowing for smooth panel adjustments without any “getting stuck.”

Non-movable Side Panel

The non-movable panel is attached to the upper and lower boards with screws. The panel is made from three grooves and a back beam. We use strong aluminum alloy for this beam, which holds everything together securely. The edges are smooth, allowing for quick panel insertion.

Adjustable Side Panel

The adjustable panel fits into a groove and uses a snap-fit design. You can slide it to change the distance between the panels. This feature helps you store PCBs of different sizes easily.

Vertical Columns for Strength

The vertical columns are made through an aluminum extrusion process. Each column has a wall thickness of 2mm. This design keeps the structure strong while reducing the overall weight of the rack.

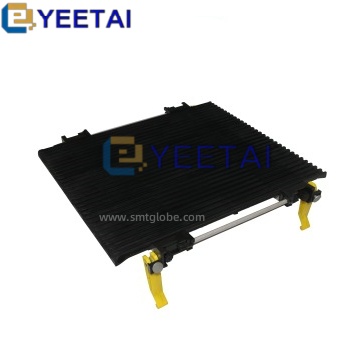

Specification

| Adjustment method | Screw adjustment | |

| Specifications | ●Outer dimensions: | 355*31 5*365mm |

| ●Reference position: | A: 34mm; B: 35.5mm | |

| ●Adjustable width: | 90-250mm | |

| ●Groove depth: | 3.5mm | |

| ●Slot width: | 7mm | |

| ●Pitch: | 10mm | |

| ●Number of slots: | 30 | |

| ●Weight: | 3.55Kg | |

| ●Carrying: | 12kg | |

| Product Description | ◆Baffle mechanism: spring lever | |

| ◆Static electricity index: 10e4-10e8 | ||

| ◆Side panel structure: full page | ||

| ◆Base plate material: plastic base plate | ||

| Temperature resistant | 口80°C | |

| Optional accessories | Poka-yoke labels | |

7 Steps to Assemble an SMT ESD Magazine Rack Correctly

Assembling our SMT ESD magazine rack is simple and saves time. Follow these steps for easy assembly:

1.Prepare the Top Panels

You will find two top panels. They look alike, but make sure to know which side is inner and outer. The columns attach to the inner side.

2. Install the Vertical Columns

Insert the columns into the inner sides of the top boards. Use the included Allen screws to secure them tightly.

Note: Always add washers under the screws.

3.Attach the Non-movable Panel

Align the holes of the non-movable panel with those on the bottom board. Secure it with Allen screws.

Note: Don’t forget to use washers.

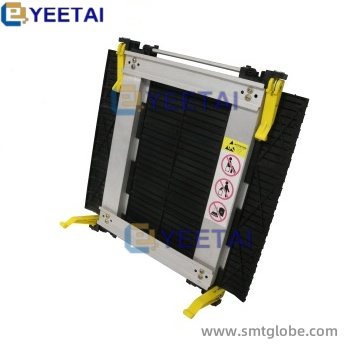

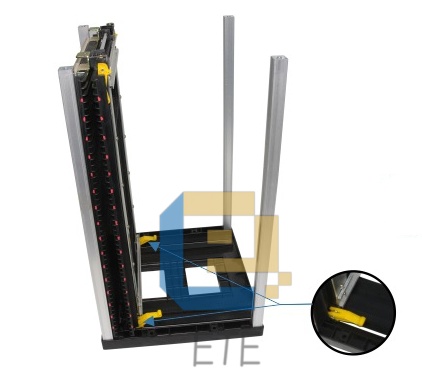

4.Install the Adjustable Panel

Aim the snap-fit mechanism of the adjustable panel at the groove. Insert the circular head into the groove for holding. Ensure the mechanism clicks into place.

5.Attach the Upper Top Panels

Place the upper board with the inner side facing inwards. Adjust all parts until they line up with the holes. Then, secure with Allen screws.

Note: Add washers here as well.

6.Adjust the Position of the Adjustable Panel

Open the four snap-fits on the adjustable panel. Press it down evenly into the sliding groove.

Note: Check all snap-fits to ensure they fit correctly; adjust by hand if needed.

7.Secure the Adjustable Panel

Move the adjustable panel to fit your PCB width. Press down all four snap-fits to lock the panel into place.

Conclusion

In conclusion, an SMT ESD magazine rack is essential for organized PCB storage. Its simple design allows for quick assembly and easy adjustments. By following the steps above, you can set up your rack with ease. If you have any questions, feel free to contact us for support!

Fine More SMT ESD Magazine Rack to suit your needs in below chart.

| Magazine Rack Dimension LxWxH (mm) | PCB Width(mm) | Slot Length(mm) | PCB Storage Qty(pcs) | Surface Resistance |

| 355x320x263 | 50-250 | 350 | 20 | Surface Resistance: 10^4-10^6 ohms System Resistance: <=10^9 ohms Test environment :25± RH: 55%±5% |

| 355x315x315 | 90-250 | 350 | 25 | |

| 355x315x365 | 90-250 | 350 | 30 | |

| 355x320x563 | 50-250 | 350 | 50 | |

| 355x320x565 | 50-240 | 350 | 50 | |

| 465x400x563 | 50-330 | 460 | 50 | |

| 535x460x570 | 50-390 | 530 | 50 | |

| 535x530x570 | 120-460 | 530 | 50 |

Other models as below list.

smt-esd-magazine-rack-355x320x263mm