Introducing the ETE-AGV-H03, a lightweight and energy-efficient SMT AGV machine designed for the electronic manufacturing industry. Perfect for applications such as transporting wave soldering fixtures and delivering materials along production lines, this intelligent transport cart enhances efficiency in your manufacturing processes.

Key Features of the ETE-AGV-H03 SMT AGV Machine

- High Load Capacity: Supports up to 50 kg, making it ideal for handling various materials in your production line.

- Flexible Startup Options: Easily start the AGV with three methods: manual, timed, or remote control.

- Voice Alerts: The ETE-AGV-H03 features a voice reminder system that notifies users about:

- Obstacles in the path: “Obstacle ahead, please remove it promptly.”

- Arrival at stations: “AGV Robot has arrived at the station.”

- Derail alerts: “AGV Robot has derailed, please reset it.”

- Versatile Charging Methods:

- Manual charging for direct power supply.

- Battery replacement for quick swaps.

- Automatic charging station for hassle-free recharging.

- Intelligent Notifications: The AGV machine alerts users when the battery is low, ensuring smooth operation without interruptions.

- Robust Warranty: Enjoy peace of mind with a one-year warranty on the unit and a two-year warranty on the battery.

- Free Accessory Package: Each unit comes with a complimentary accessory pack to get you started.

- Extended Battery Life: Features a lithium battery providing up to 20 hours of continuous operation, with customizable runtime options available based on your needs.

Specification

| Model | ETE-AGV-H03 |

| Navigation | Magnetic strip navigation, two-way driving |

| Maximum load | 40KG |

| Operation mode | Single line operation, loop line operation branch line (customizable route) |

| Maximum speed | 20-40 meters/minute (adjustable speed) |

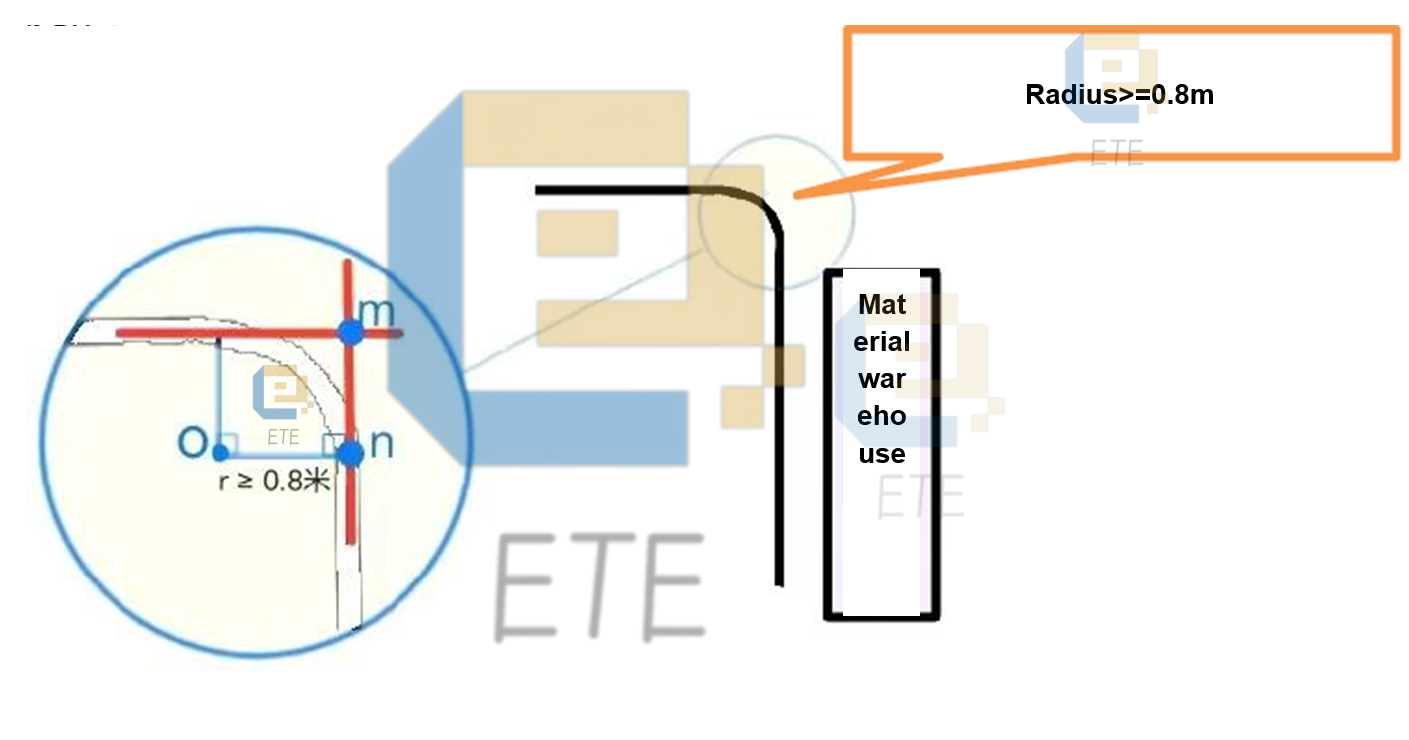

| Turning radius | 0.8M |

| Stopping accuracy | 2 cm |

| Battery Type | Lithium battery 24V20AH |

| Battery life | 20 hours (time can be customized) |

| Standby time | 200 hours |

| Charging time | 5 hours |

| Body size (mm) | Length 370X Width 430X Height 550 |

| Item placement table size (mm) | Length 370X Width 430X Height 50 |

| AGV weight | 26KG |

| operating instructions | Front and rear LED lights; running indicator light + flashing red light when there are obstacles |

| Drive mode | Brushless motor differential ratio |

| Obstacle detection method | Infrared sensor |

| Touch anti-collision switch strip | One at the front and one at the front |

| Human Interface | 4.3-inch high-definition touch screen |

| Automatic route planning | Can set automatic running routes |

| Start mode | Manual start + scheduled start + remote control start; wireless serial port communication can be added to support secondary development |

| Site selection | 10 sites choose RFID card identification |

| charging method | Manually charge the car directly\replace the battery |

| Power display | Automatic alarm for power shortage |

| Standard accessories | 20 meters magnetic navigation strip, 10 RFID site cards, 4 deceleration cards, 5A charger |

| Warranty time | 12 months |

Configuration of the ETE-AGV-H03

- Safety Infrared Sensors: Automatically stops the AGV machine upon detecting obstacles, preventing collisions and ensuring safety.

- Compact Turning Radius: Boasts a turning radius of 0.8 meters, allowing for maneuverability in small spaces.

- Programmable Routes: Easily set up automatic running routes to streamline operations on your production floor.

- Efficient Drive System: Equipped with a brushless motor and differential drive for smooth and reliable movement.

- User-Friendly Touch Screen: Features a 4.5-inch high-definition touch screen for intuitive operation.

- Comprehensive Remote Control: Includes a 15-key remote for precise control over navigation, capable of operating in various modes.

Operating Modes for the ETE-AGV-H03 SMT AGV Machine

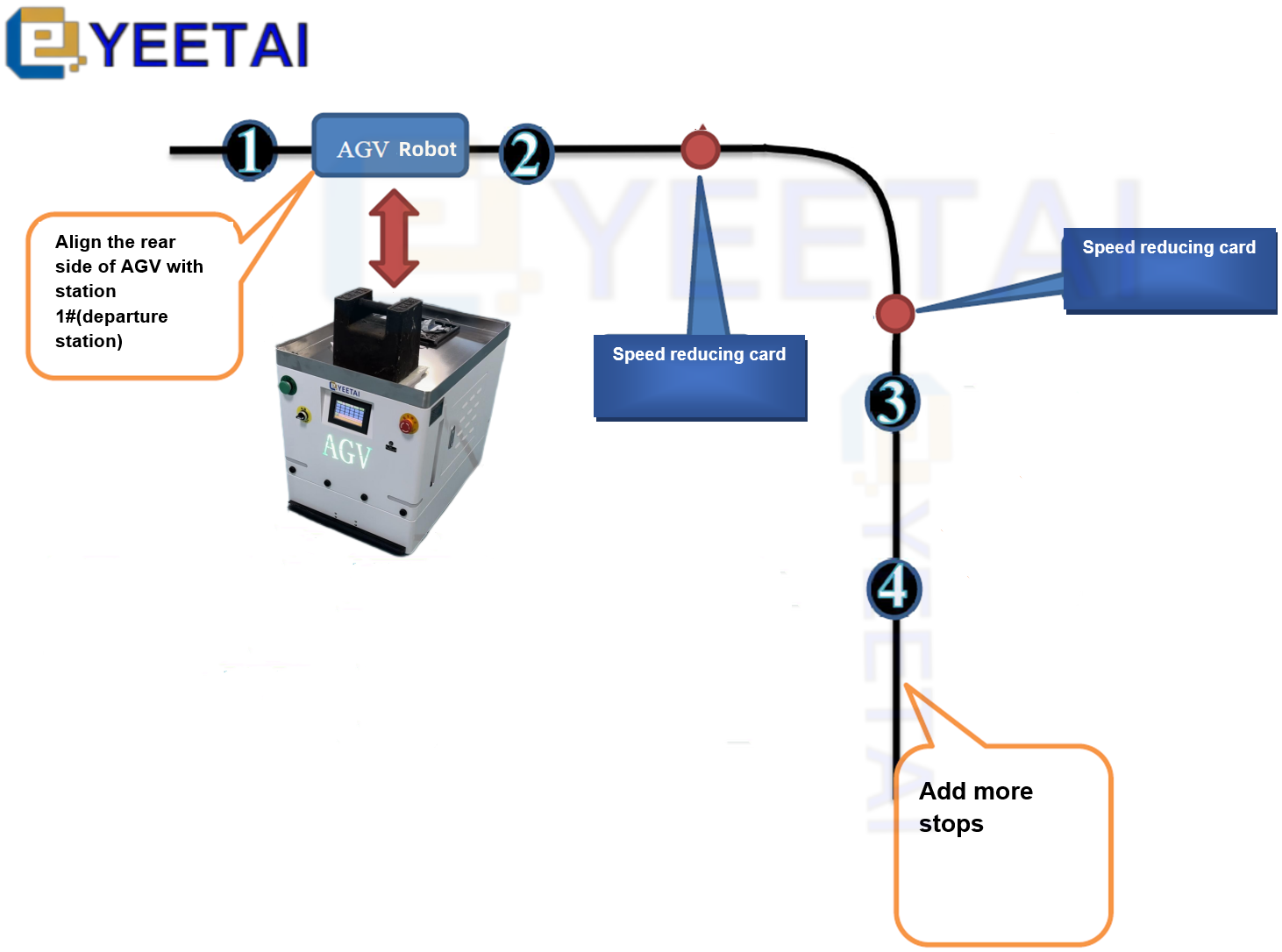

- Single Line Mode:

- Place stations in sequence with at least 1 meter of distance between them.

- Ensure the turning radius remains no less than 0.8 meters.

- For increased speeds (over 80%), utilize deceleration markers before completing turns to maintain stable navigation.

- Loop Mode:

- Configure a closed-loop magnetic strip for the AGV to run within.

- Place RFID station cards in ascending order along the magnetic strip, with a minimum distance of 1 meter between them.

- The AGV will automatically determine the most efficient route, deciding whether to move forward or backward.

- Branch Line Mode:

- Set directional preferences:

- Choose 1 for left turns upon reading a branch RFID card.

- Choose 2 for right turns.

- Set directional preferences:

- Remote Control Operation:

- Utilize remote control features for selecting stations 1-13.

- Control the AGV’s navigation both along the magnetic strip and off-track with keys 1-5.

How to tag magnetic navigation strips?

Paste the magnetic strip into a closed-loop circuit, the SMT AGV machine runs in the closed circuit. Put the RFID station card on the installation navigation magnetic strip. Place the site cards in order from low value to high value. The distance between the neighboring stations is not less than 1 meter. In the circle route, the AGV automatically calculates about what is the nearest station, and automatically judges that it is going forward go or go back.

Conclusion

The ETE-AGV-H03 is a highly efficient SMT AGV machine that enhances productivity and safety in electronic manufacturing environments. Contact us today for more information or to discuss how our various AGV models can meet your specific SMT factory needs, including:

- ETE-AGV-910A

- ETE-AGV30-C

- ETE-AGV100-T

- SMT Loader AGV for ESD Magazine Rack | ETE-AGV-LM01

- AGV Robot for Moving Wave Soldering Pallet | ETE-AGV100

- ETE-AGV30

Improve your production line efficiency with the ETE-AGV-H03 — the ultimate solution for all your material handling needs!