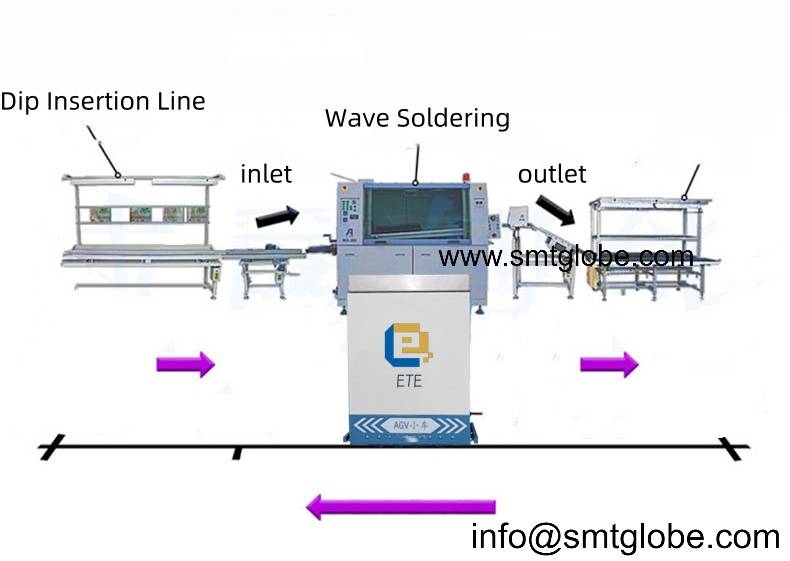

Our SMT AGV Equipment ETE-AGV30-C is for moving wave soldering pallet,PCB and PCB fixture.It offers automation for a SMT factory. It is also helpful to SMT material handling and SMT warehouse and logistic. Besides, the wave soldering pallet AGV’s self-guided driving offers cost-saving and efficient transport solutions for SMT production lines and PCB assembly. The SMT AGV robot‘s advanced lithium battery technology offers great convenience about power supply.Prevents machine downtime.

Key Features of SMT AGV Equipment for Moving Wave Soldering Pallets

1. High Load Capacity

- Supports Up to 30kg: The SMT AGV Equipment for Moving Wave Soldering Pallets efficiently handles heavy loads, ensuring safe transportation of materials within your factory.

2. Multiple Starting Options

- Manual and Delayed Start: Choose between manual and delayed startup options, allowing for flexible operation tailored to your workflow.

3. Efficient Charging Solutions

- Versatile Charging Methods: Charge the AGV manually or replace the battery for quick recharging. An optional wireless automatic charging station ensures contactless, safe charging while minimizing downtime.

4. Intelligent Alerts

- Low Battery Alarm: The SMT AGV Equipment for Moving Wave Soldering Pallets automatically alerts operators when battery levels are low, preventing potential disruptions in production.

5. Long-Lasting Performance

- Continuous Operation: Equipped with a specialized lithium battery, the AGV can run for up to 50 hours continuously. Custom battery runtime options are also available according to your needs.

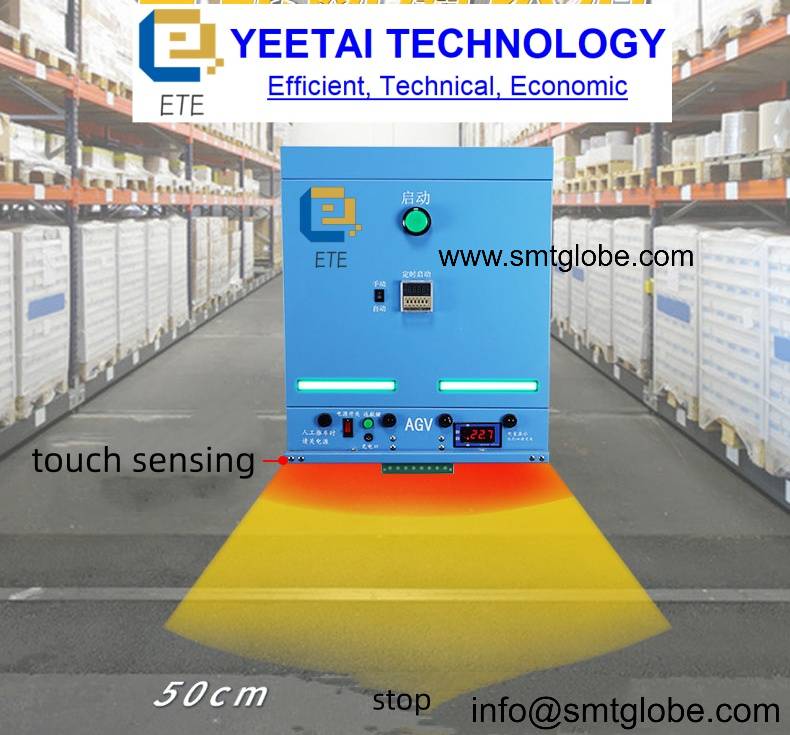

6. Advanced Safety Features

- Infrared Obstacle Sensors: The AGV includes infrared sensors that can detect obstacles within 50cm, ensuring it automatically stops to prevent collisions and accidents.

Specification

| Model | ETE-AGV30-C |

| Navigation | Magnetic strip navigation, two-way driving |

| Maximum load | 30KG |

| Operation mode | Single line operation |

| Maximum speed | 40m/min |

| Stopping accuracy | 5cm |

| Battery Type | lithium battery |

| Battery life | 20/50 hours |

| Standby time | 200 hours |

| Charging time | 5 hours |

| Body size (mm) | Length 370X Width 430X Height 520 |

| Item placement table size (mm) | Length 370X Width 430X Height 50 |

| Car’s own weight | 22KG |

| Obstacle detection method | Front and rear LED lights; running indicator light + flashing red light when there are obstacles; infrared sensor |

| Drive mode | differential drive |

| Touch anti-collision switch strip | One at the front and one at the front |

| Voltage display | digital voltmeter |

| Site selection | Multi-site operation |

| Start mode | Manual start + scheduled start |

| charging method | Manually charge the car directly\replace the battery |

| Power display | Automatic alarm for power shortage |

| Standard accessories | Magnetic navigation strip 20 meters, 3 stop lines, 5A charger |

| Warranty | 12 months |

Configuration of SMT AGV Equipment for Moving Wave Soldering Pallets

- Single Line Operation: The AGV operates on a single line for simple routing.

- Turning Radius of 1.5 Meters: Its compact design allows for smooth navigation in tight spaces.

- Custom Remote Control Option: Enhance control with a customizable remote.

- Deceleration Motor with Differential Drive: This feature ensures efficient and smooth movement.

- Multi-Station Purpose: The AGV can stop at multiple preset stations, improving productivity.

- Delay Start at Stations: Configure delayed start times for each station to optimize workflow.

Advantages of Using SMT AGV Equipment for Moving Wave Soldering Pallets

- Powerful Performance: Designed to excel in heavy-duty environments.

- Extended Work Hours: Continuous operation for up to 50 hours between charges.

- User-Friendly Operations: One-button start for easy engagement.

- Customizable Features: Adjustable start times to align with factory schedules.

How to install and use the SMT AGV Equipment?

5.1 Firstly let us know the AGV direction.

5.2 How to make AGV drive in a signal line?

Put the RFID site card on the installation navigation magnetic strip, and place the site card in sequence.

The distance between the site and the previous site is not less than 1 meter.

If you want the vehicle speed to be more than 80% or faster, it tends to drive out of the navigation strips when turning. Thus,a speed reducing card should be attached to the strip 0.5m in front of the turning(see drawing above). And the other speed reducing card should be attached to the strip after turning(also 0.5m).

Conclusion

Investing in SMT AGV Equipment for Moving Wave Soldering Pallets from YEETAI is a strategic move for SMT factories aiming to boost efficiency and reduce labor costs. The ETE-AGV30-C combines high load capacity, intelligent features, safety, and flexibility to support smooth operations in your manufacturing process.

For more information about our SMT AGV Equipment for Moving Wave Soldering Pallets and how it can enhance your production lines, please contact us today!

SMT loader AGV for ESD magazine rack | ETE-AGV-LM01