SMD Component Counter for EMS SMT Factories

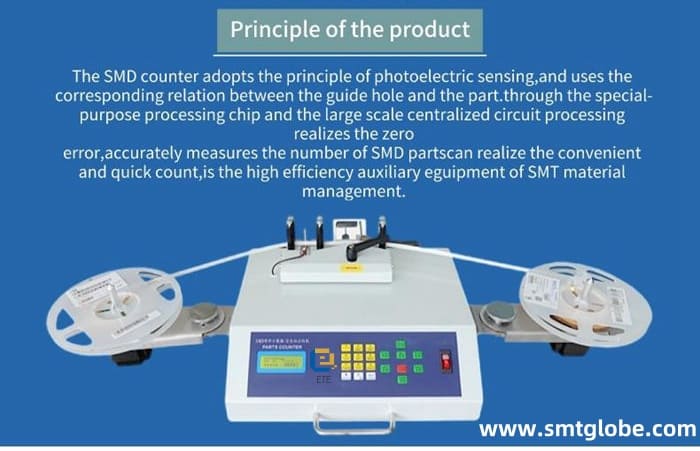

We offer a state-of-the-art SMD Component Counter designed specifically for EMS SMT factories. This innovative device uses photoelectric sensing technology to accurately measure SMD part quantities by analyzing the relationship between the guide hole and the component. With advanced processing chips and centralized circuit processing, our counter achieves zero errors, making it an essential tool for efficient SMT material management.

Key Benefits

- Automatic Counting: Streamlines the calculation of part quantities for easy material handling.

- User-Friendly Operations: Simplified material distribution, allowing for efficient workflow.

- Durability: Features a unique anti-fall design that minimizes damage to the material tape.

- Versatile Counting: Capable of counting in both forward and reverse directions, with preset quantity options for precise calculations.

- Accurate Measurement: Guarantees zero error in count, ensuring reliable material management.

- Enhanced Workflow Management: Optional scanning gun and barcode printer for effective tracking of components.

Specs

Model: E-801E

Voltage: AC220V/AC100V 50/60HZ

Counting Range: -99999_99999PCS

Machine Size: LxWxH=780x350x200mm

Machine Weight: 10-11kg

Component pitch: 1,2,4,8,10,12,16,24,32,44,56mm etc.

Fast and Efficient

The E-801E SMD Component Counter enhances productivity by enabling quick setup and changeover. It can process an entire reel of components in just 90 seconds, including a double-check feature to ensure counting accuracy. Advanced technology minimizes noise during operation, and the English LCD screen interface makes it straightforward for operators to read and manage.

User-Friendly Design

The E-801E design allows operators to closely monitor both the LCD screen and the components being counted, ensuring accuracy throughout the process. Key design elements include:

- Prevention of Tape Dropping: Protects the integrity of the tape and prevents damage during counting.

- Dual Counting Directions: Enables operators to double-check counts efficiently.

- Rewind Capability: Facilitates returning parts to their original reels, maintaining organization.

Setup Instructions

To set up the SMD Component Counter correctly, follow these steps:

- Positioning: Place the reel on the left side of the counter, and position a temporary reel on the right side. Manually guide the tape through the counting gears and rotate the temporary reel until the first component aligns with the press wheel.

- Adjusting Pitch: Set the pitch value according to the specified guidelines for accurate counting.

- Starting the Count: Press the START key to begin the counting process. The counter will increment or decrement based on motor movement or manual adjustments.

- Rewinding: After verifying the counting result, use the REWIND key to return the tape to its original reel.

Safety Precautions

Before using the SMD Component Counter, please observe the following precautions:

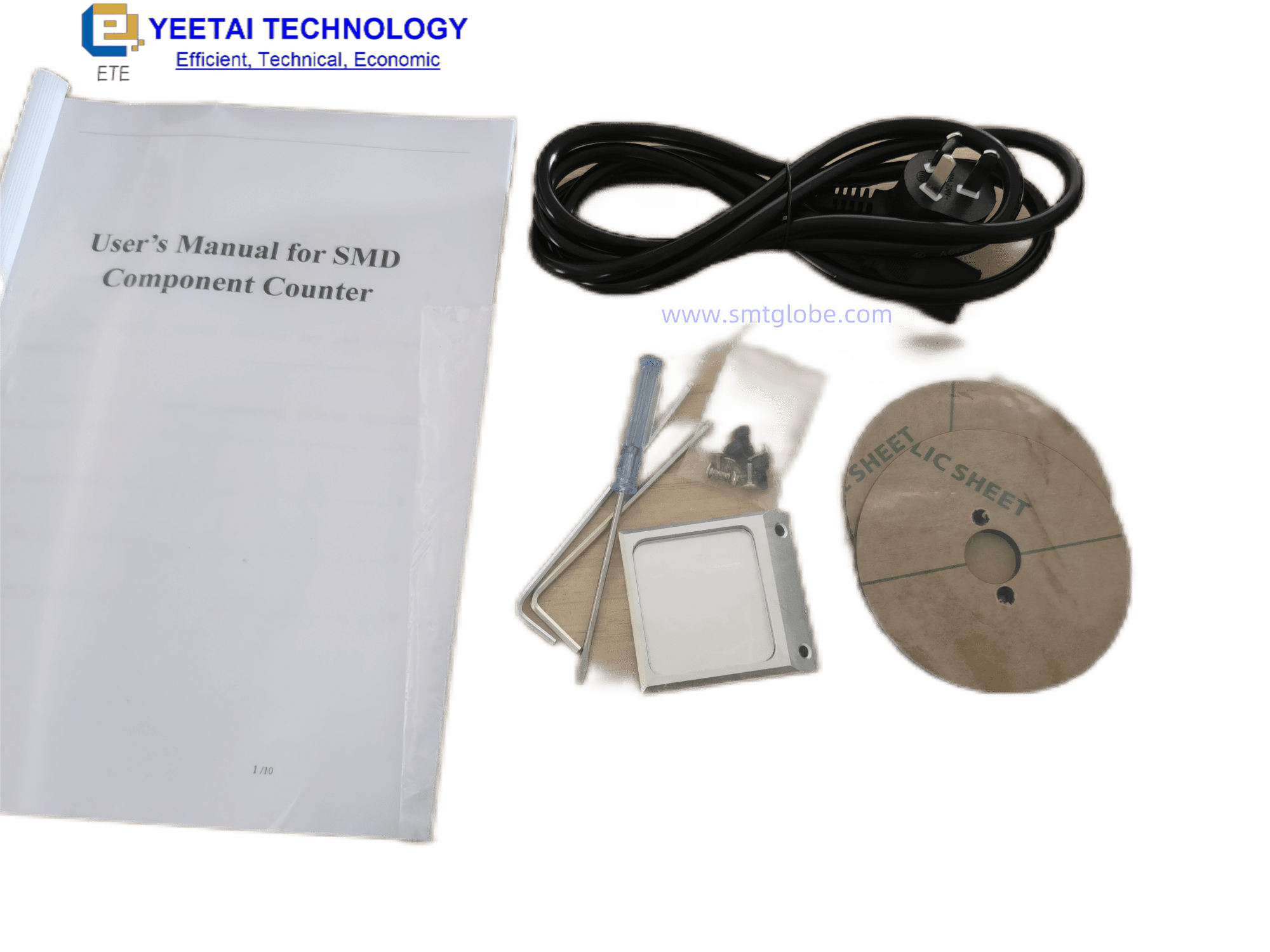

- Check Attachments: Upon unpacking, verify that all attachments are complete.

- Read Operational Manual: Carefully review the operation manual to ensure safe and effective usage.

- Voltage Verification: Confirm that the voltage specification matches the municipal power supply.

- Ground Connection: Ensure the ground wire is connected to safeguard both operators and equipment.

Installation Instructions

Tray Installation: Use two M4 hexagon screws to fix the rocket head onto the motor shaft. Maintain a height of 6-7mm between the bottom of the rocket head and the arm’s plane.

Frame Installation: Secure the frame to the two M4 holes located at the back of the machine using two M4 hexagon screws. Remember to remove the protective film from the lens before use.

If you need any more models, please visit our website or read below lists.