The SMD Counter offers a unique voice notice when finishing the last component. It also features Missing Part Detection which goes beyond simply counting slot holes. SMD Counter verifies the presence of components in each slot, stopping the machine and alerting the operator if any parts are missing. The digital readout continuously updates the true part count by subtracting any missing components. Additionally, the missing part detection feature prevents the inconvenience of spinning tape whiplash by stopping at the end of new reels.

Features

The SMD Counter enables quick setup and changeover. Whether counting out a full reel or a specific quantity of parts, the double-check feature ensures accuracy. Additionally, the E-882V is fast, capable of processing an entire reel of components in just ninety seconds, including double-checking the count. With its missing part detection capability, the Smart SMD counting machine is well suitable for SMT material inventory management, stock checks, intake counts, pre-kitting, and various other applications.

Specification

Model: E-882V

Voltage: AC220V/AC100V 50/60HZ

Rated power: 80W

Counting Range: -16777216_16777216PCS

Machine Size: LxWxH=730x230x270mm

Machine Weight: 10-11kg

Component pitch: 1,2,4,8,10,12,16,24,32,44,56mm etc.

Easy to use

The design of the E-882V allows operators to monitor both the LCD screen and the parts under counting, ensuring accuracy. Additionally, the counter prevents tape dropping and protect tapes from damage during the counting process. It can count in both forward and reverse directions for double-checking purposes, and parts can be efficiently spooled back to their original reel.

Operation Process

Set the decimal mode operation

1) Connect the power cord to the host and connect the AC220V power supply.

2) Turn on the POWER switch of the machine panel, and the LCD panel will

shine .

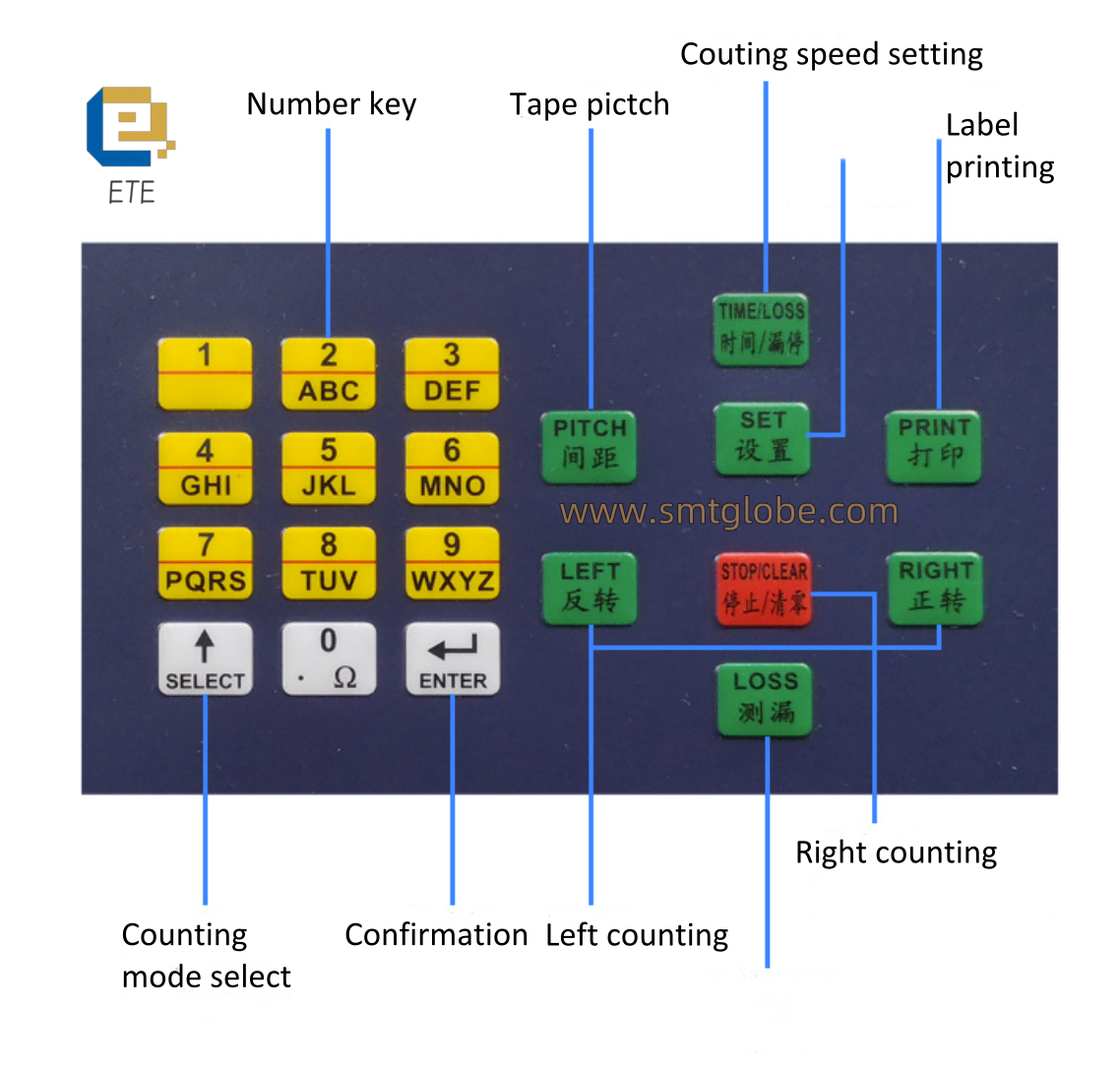

3) Press PITCH to set the spacing of parts to be counted and press “ENTER”.

Place the parts to count on the left side tray.

4) Manually pull out the material belt between the stop sheet and the

counting gear (as shown in Figure 1 below), and align the middle of the

first part and space with the middle line of the stop sheet (as shown in

Figure 2 below).

5) Press the “stop/reset” button for 2 seconds to return the number to

zero. Note: when pulling the material belt, the counting gear will rotate

and count.

6) Press the “Set key” to switch to select set decimal material mode (00000

is displayed in the lower left corner). When selecting set decimal

material mode, you must enter the desired quantity, otherwise the motor

will not rotate according to “positive rotation”.

7) Pull the material belt by hand and wind it to the empty material plate.

Press “forward /RIGHT” to count.

8) The motor will stop when the quantity arrives. Due to the inertia

principle, the number of counts may be more or less than the set value

of about 1, which can be manually rotated to the LCD display set valuein the direction of the material disk, that is, the number of parts. (as

shown in Figure 3 below)

9) After counting, press “reverse /LEFT” tape and then roll it back to

the original LEFT panel, and then stop rotating.