The ETE-ARM-810A Slam Laser AGV a lightweight, low-power, and high-endurance portable intelligent handling cart specifically designed for the SMT (Surface Mount Technology) industry. This innovative robot is perfect for efficiently transporting wave soldering pallets and enhancing productivity across various manufacturing processes, including DIP insertion lines and PCB assembly.

Wave Soldering Pallet AGV ETE-AGV60

Key Features of the ETE-ARM-810A Slam Laser AGV ARM for Wave Soldering Pallet

Advanced Navigation System

The ETE-ARM-810A Slam Laser AGV ARM employs cutting-edge laser navigation technology, eliminating the need for magnetic strips. This feature not only simplifies setup but also maintains a clean and organized workspace, which is essential in SMT production environments. The robot autonomously maps its surroundings, navigates optimally, and circumvents obstacles, ensuring uninterrupted operations.

Robust Design and Functionality

Built on a square chassis, the ARM robot serves as the core of indoor autonomous driving systems. It follows a precise sequence of “Mapping ➜ Point Marking ➜ Navigation,” allowing for both single-point and multi-point navigation capabilities. The robot also includes a virtual wall function to safeguard against obstacles during operation.

Versatile Applications

The ETE-ARM-810A is specifically designed for various applications within the SMT industry, enabling flexible movement of PCB fixtures and components between different workspaces. Its ability to seamlessly transport wave soldering pallets between multiple DIP insertion lines enhances efficiency and speeds up production timelines, making it a vital asset for any modern electronics manufacturer.

Enhanced Obstacle Avoidance

Equipped with a 30-meter radius DTOF laser radar and multiple sensors, this robot ensures real-time obstacle avoidance and accurate mapping of its environment. Such capabilities are crucial in high-density production areas, especially where movement between PCB fixtures and DIP insertion lines is frequent.

User-Friendly Interface

The ARM robot for wave soldering pallet comes with a user-friendly Android app that simplifies the initial mapping and navigation processes. This intuitive interface allows operators to quickly set up the robot, manage maps, mark points, and program automatic charging routines.

Multi-Map Functionality

The robot supports the creation and management of multiple maps, making it adaptable for environments with various layouts, including multiple floors. This function is particularly advantageous for facilities with intricate systems of wave soldering pallets and DIP insertion lines.

Operating Environment

Temperature Range: -10℃ to 40℃

Humidity: Less than 80% RH with no condensation or frost. Please avoid exposure to excessive dust or corrosive materials.

Best Practices for Use

To maximize the performance of the ETE-ARM-810A ARM Robot:

Ensure it operates on solid and even surfaces.

Avoid environments with soft flooring or excessive obstacles.

Use the virtual wall feature for hazardous areas, such as edges or glass.

Regularly maintain the robot and keep its sensors clean for optimal navigation performance.

Specification

| Model | ETE-ARM-810A |

| Navigation | When a target point is specified, the robot can drive there automatically |

| Maximum load | 100KG |

| Operation mode | Realize single-point and multi-point navigation functions for automatically planning paths |

| speed | 20-40 meters/minute/(adjustable speed) |

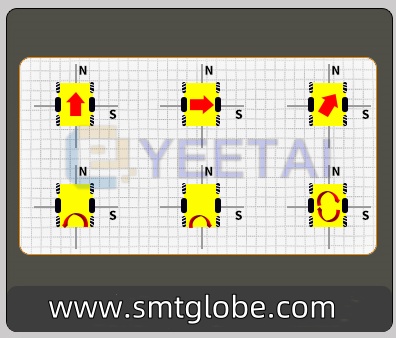

| Minimum turning radius | Can turn 360 degrees on the spot |

| Stopping accuracy | 2CM |

| Battery Type | Management battery 24V20AH |

| Battery life | 10h (time can be customized) |

| Standby time | 200 hours |

| Charging time | 5 hours |

| Body size (mm) | Length 500 Width 415 Height 500 |

| Car’s own weight | 60KG |

| lidar | 0m radius DTOF radar, measurement frequency >30KHZ |

| operating instructions | Front and rear LED lights: flash blue when running |

| Chassis structure | 6-wheel structure (2 driving wheels and 4 driven wheels), differential turning |

| Obstacle detection method | Standard configuration: 4 TOF depth cameras (maximum 8), 4 ultrasonic sensors |

| Virtual wall function | It can be divided through the virtual wall function, and the machine will automatically avoid these areas during navigation. |

| Human-machine page | CR1 comes standard with an 8-inch nuclear safety board and a 7-inch LCD display touch screen |

| Automatic route planning | The machine can create multiple maps, call the corresponding map when needed, and switch between multiple floors. |

| Remote control motion function | You can remotely control the machine by installing the developer ADD that comes with the Android board on your phone. |

| Mapping function | The machine uses its own laser radar to record the mapping system and perform navigation markings. |

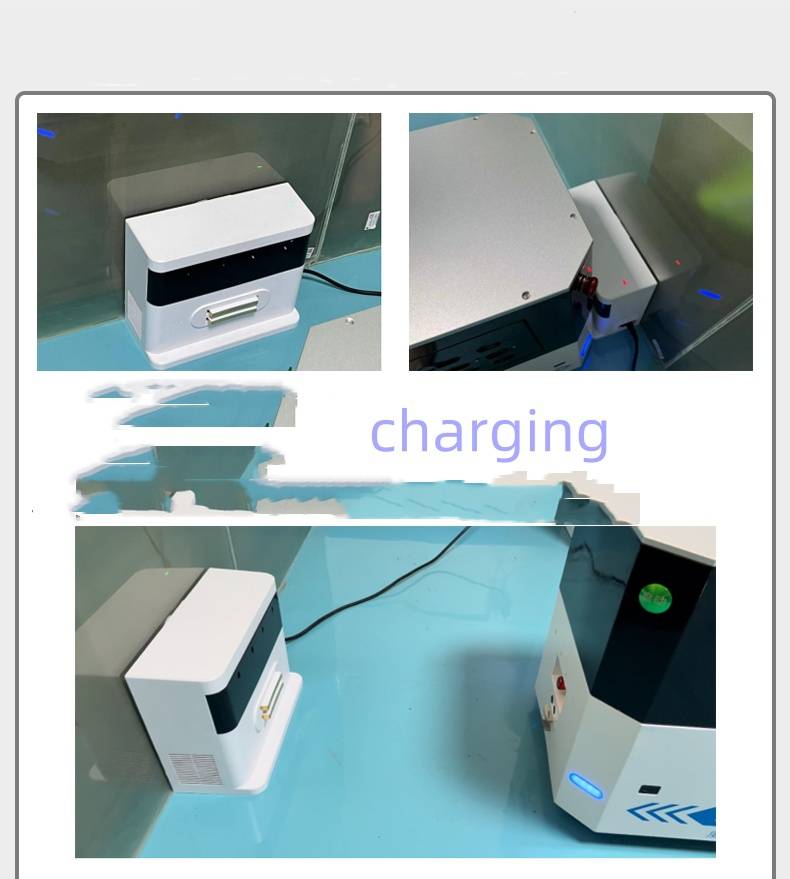

| charging method | The distribution charging pile can charge automatically and has a manual charging port. |

| Automatic charging function | Automatic charging can be set in various states, such as idle charging, low battery charging, one-button charging, etc. |

| Standard accessories | 20-meter magnetic navigation strip, 20 RFID site cards, 6 deceleration cards, 4 obstacle avoidance cards, 5A charger |

| warranty period | One year for the whole vehicle |

Product Dimensions: 504 * 415 * 282 mm; Weight: approximately 35 kg

Battery Capacity: 20 Ah (504 Wh) with standard voltage at 25.2 V

Charging Options: Automatic charging in 5 hours or manual emergency charging within 15 hours

Maximum Load Capacity: 100 kg, ideally suited for handling wave soldering pallets

Endurance: Around 13 hours of operation without load

Slam Laser AGV ARM Configuration

LED Smart Touch Display

Laser Radar Recognition for Automatic Obstacle Avoidance

Real-time Control via Mobile APP

Wireless Communication and Monitoring via Computer

Omnidirectional Movement with Six-Wheel Structure

Automatic Charging Station

Lithium Iron Phosphate Battery

Conclusion

The ETE-ARM-810A Slam Laser AGV ARM is a game-changer for the SMT industry, particularly for transporting wave soldering pallets and navigating DIP insertion lines. With its advanced navigation capabilities and robust design, it enhances efficiency in manufacturing processes while ensuring safety and reliability.

If you are looking to streamline your operations and improve the handling of PCB fixtures, consider integrating the ETE-ARM-810A into your workflow for a significant boost in productivity

We also have other AGV Robots.