High-Performance Selective Conformal Coating Machine for PCB Surface Coating

In today’s manufacturing landscape, getting a balance between production quantity, material costs, labor investment, and safety is essential. Additionally, ensuring compliance with industry regulations and addressing environmental concerns is important. Our Selective Conformal Coating Machine offers an ideal solution, delivering precise, high-speed, and safe surface coating with superior process control capabilities.

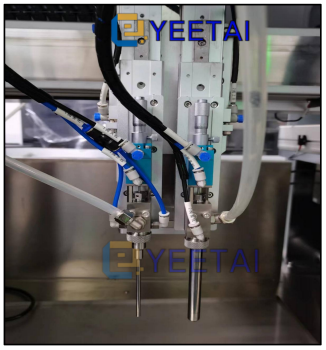

With various valve configurations, this machine meets diverse selective precision requirements, including edge clarity, coating thickness, and operational efficiency. Manufacturers can significantly reduce costs while enhancing production output and yield quality.

Key Features of Our Selective Conformal Coating Machine

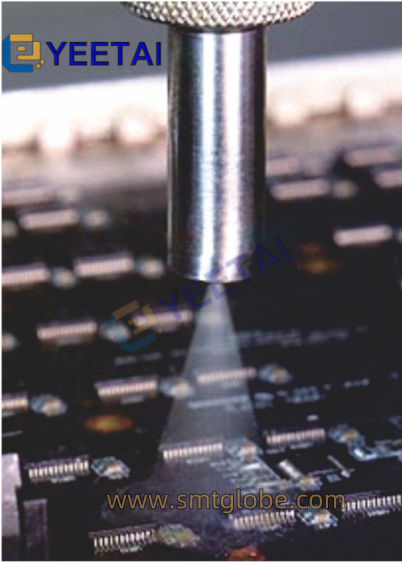

- High Precision: Operates with a repeatability accuracy of ±0.02mm, achieving coating thicknesses between 0.03mm and 0.2mm.

- High Quality: Delivers uniform coatings that are bubble-free and wave-free, ensuring a smooth finish.

- Non-Contact Application: Our non-contact coating technology protects delicate components effectively.

- Materials Savings: The machine features controllable flow, minimizing drips and reducing waste.

- User-Friendly Operation: Simple program editing means operators can typically master machine use within a day.

- Practical Performance: Coated surfaces meet ESD standards and offer reworkability advantages.

- Broad Application Compatibility: Capable of executing surface, point, line, and curve coatings, as well as various irregular trajectories.

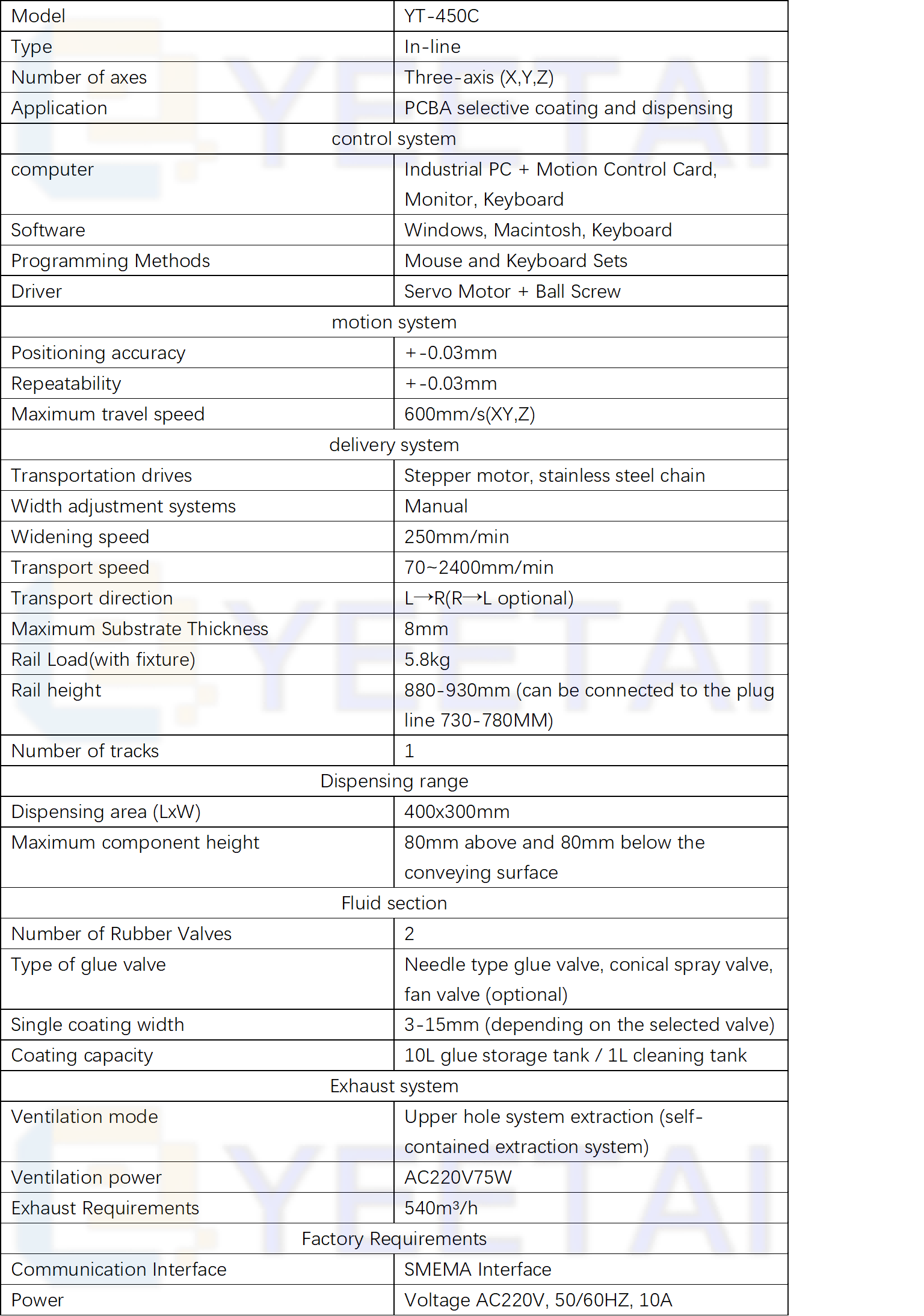

Specification

Industries Served

Our selective conformal coating machine is designed for a wide range of applications, including:

- PCB Integrated Circuit Boards

- Automotive Electronic Control Boards

- Aerospace Instrument Panels

- FPC Printed Circuit Boards

- Microcomputer Control Boards

- Semiconductor Crystal Line Protection

- Appliance Controllers

- LED Coating Processes

Advantages of Using Our Machine

- Consistent Quality: Ensures uniform application of protective coatings, contributing to high product consistency and reliable quality.

- Superior Precision: Achieves selective coating that surpasses manual methods in uniformity and accuracy.

- Cost Savings: Reduces labor and material costs, eliminating the need for protective tapes and significantly lowering production expenditure.

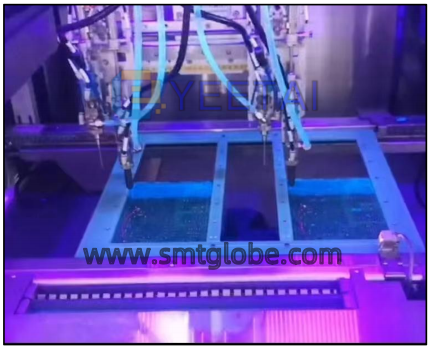

- Material Efficiency: Manual application often leads to inconsistent usage; our machine provides selective, atomized coating, saving over 50% in material.

- Eco-Friendly Design: The machine operates with low power consumption, featuring a fully enclosed structure with advanced waste gas recovery systems, ensuring a safe and healthy work environment.

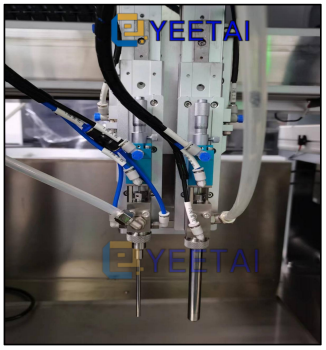

Advanced Machine Configuration

- Built-in Negative Pressure Exhaust System: Helps eliminate unpleasant odors and improves air quality in the workshop.

- High-Precision, Fully Enclosed Silent Module: Ensures quiet operation.

- Robust Fluid Equipment Motion Module: Reduces wear on components and simplifies maintenance.

- Durable One-Piece Metal Construction: Offers long-lasting performance.

- Integrated Industrial Control Computer: Simplifies programming and operation.

- Proprietary Coating System: Combines computer programming with advanced motion control.

- Three-Axis System Using Imported Japanese Servo Motors: Guarantees precision and reliability.

- Automatic Valve Cleaning and Fluid Soaking: Simplifies maintenance and ensures cleanliness.

- Flexible Axis Configuration: Choose between four-axis or five-axis based on specific spraying processes.

Conclusion

Our Selective Conformal Coating Machine is the perfect choice for manufacturers looking to enhance their production processes while maintaining high standards of quality, precision, and environmental responsibility. By investing in our state-of-the-art machinery, businesses can enjoy significant cost savings and improved operational efficiency.

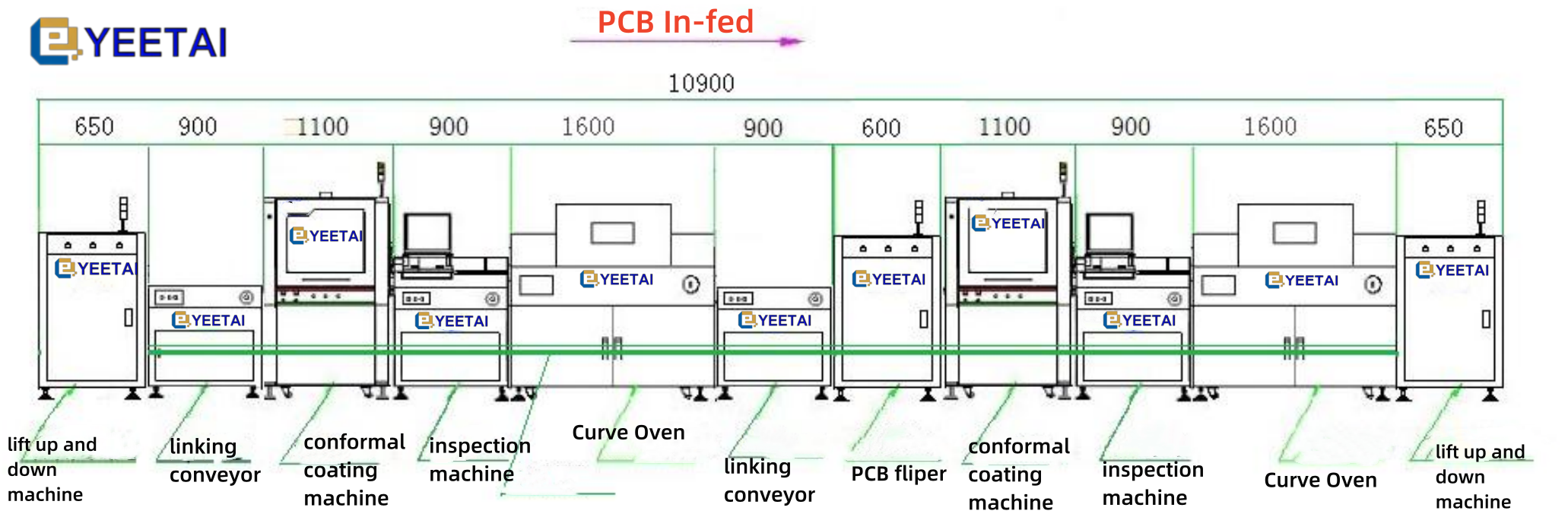

Conformal coating full line solution

We offer full line solutions of conformal coating process. You may read below pages.

Selective Conformal Coating Machine

Full conformal coating machine