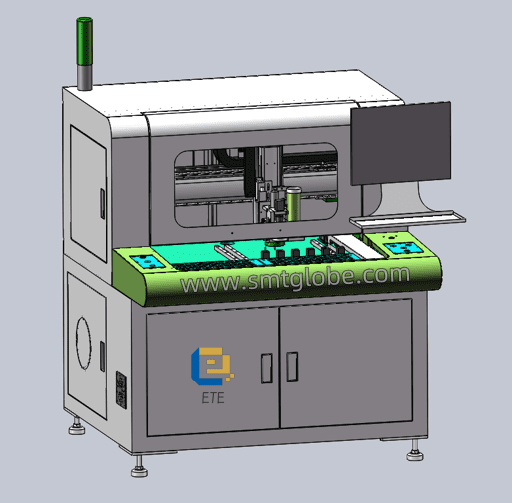

Our Router Depaneling machine is an efficient and precise equipment used to separate PCB panels into smaller units. This method improves production efficiency and enhances product quality. Below, we provide a detailed guide on the steps involved in using an automatic PCB Router Depaneling machine for separation.

Step 1: Position the PCB

Begin by placing the entire PCB panel on the machine’s worktable. The worktable typically features custom or universal fixtures designed to securely hold the PCB in place, ensuring stability during operation.

Step 2: Configure the Settings

Next, adjust the separation settings on the machine’s control interface. Input the dimensions of the PCB and specify the desired cutting length, width, depth, and speed. This customization is essential for achieving precise cuts.

Step 3: Start the Router Depaneling machine

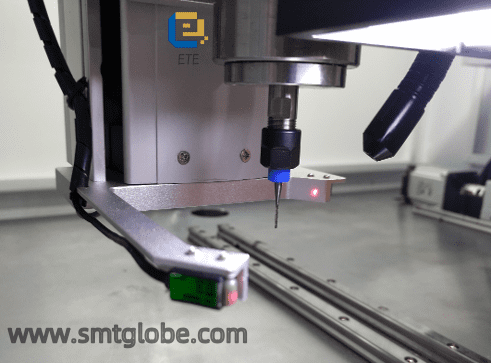

Once settings are configured, power on the Router Depaneling machine. The machine will automatically position the cutting tool at the predetermined starting point and initiate the separation process. It utilizes a high-speed rotating milling cutter to slice the PCB into smaller pieces.

Step 4: Perform the Cutting Process

During the cutting process, the machine follows a pre-set path to move the cutting tool. Equipped with high-precision rails and servo drive systems, the Router Depaneling machine ensures accurate positioning and cuts. The path can be straight, curved, or follow complex contours based on specific requirements.

Step 5: Automatic Tool Compensation

To maintain cutting precision, the Router Depaneling machine often features an intelligent tool compensation function. This adjusts the cutting depth based on the wear of the cutting tool, ensuring consistent quality throughout the operation.

Step 6: Manage Noise and Debris

Cutting generates noise and waste. The Router Depaneling machine is typically equipped with dust extraction systems and noise-reduction enclosures. These features protect operators and minimize environmental impact.

Step 7: Retrieve the Finished PCBs

Once the milling operation is complete, the machine will automatically stop and eject the separated PCB pieces. Operators can then easily remove the finished sections for further processing.

Conclusion

The process of using an offline PCB Router Depaneling machine for separation involves critical steps: positioning the PCB, configuring settings, starting the machine, cutting the board, managing debris, and retrieving the finished PCBs. Each step is designed to maximize efficiency, enhance precision, and improve production quality. By implementing these procedures, manufacturers can achieve a more effective and reliable PCB production process.

We are experienced at PCB depaneling. Know more PCB depaneling solutions in our website: www.smtglobe.com