High-Performance Router Depaneling machine for precise PCB Separation.

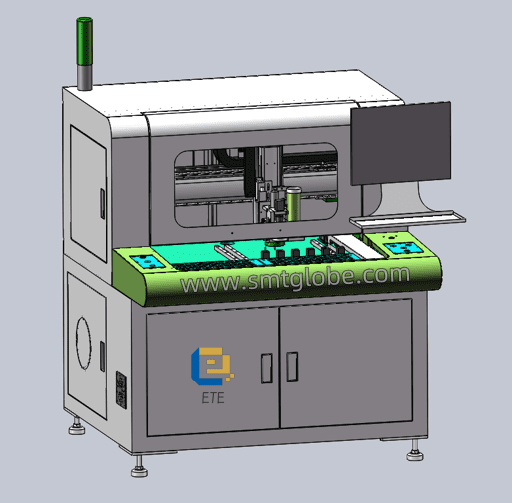

Discover our advanced router depaneling machine, designed for precise and low-stress separation of PCB panels. With dual worktables and high-speed rotating router technology, our depaneling machine offers efficient and cost-effective PCB separation while minimizing the risk of damage to electronic components. Suitable for various PCB materials and assembly methods, our router depaneling machine is ideal for consumer electronics, automotive electronics, and related industries. Experience seamless operation, enhanced production efficiency, and operator safety with our state-of-the-art PCB depaneling solution.

Features:

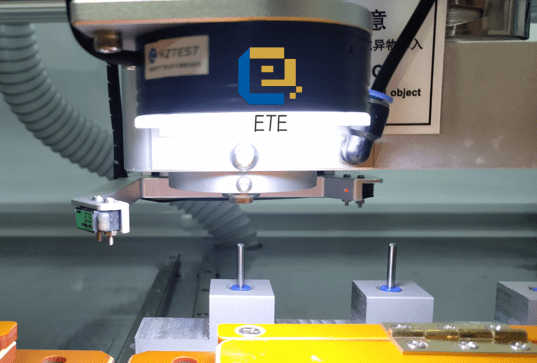

- These router depaneling machines are all offline, requiring manual placement of the PCB panel onto the machine’s worktable.

- They have two worktables, enhancing depaneling efficiency while saving costs and reducing floor space.

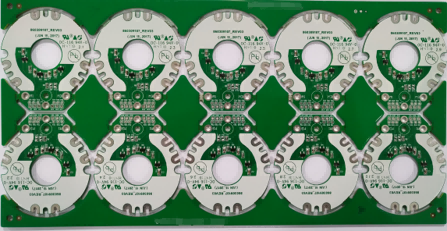

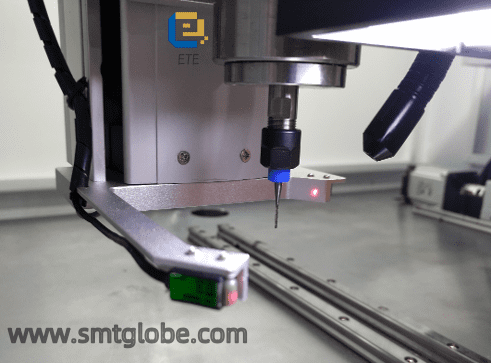

- Cutting method: High-speed rotating router for low-stress separation, preventing damage to PCBs and electronic components.

- Router Depaneling Machine is suitable for PCB panels with flat separation surfaces and various assembly methods, such as short straight lines, dots, arcs, circles, L-shaped, and via-hole connections.

- Router Depaneling equipment is compatible with PCB materials including PCBA fiberglass boards, FR4 boards, copper-based boards, and aluminum-based boards.

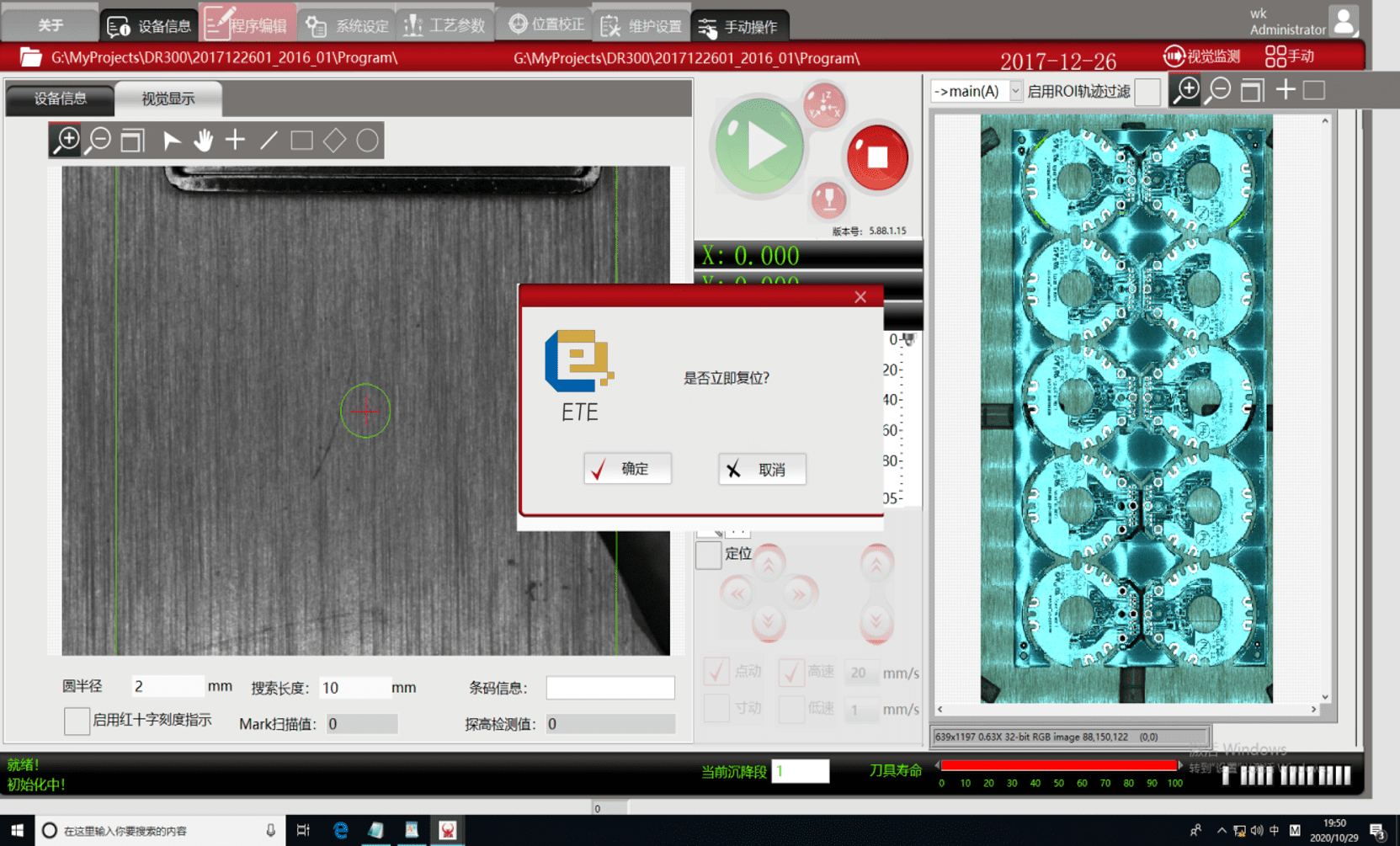

- The software interface offers both Chinese and English operating interfaces, making it user-friendly with a strong sense of hierarchy for easy operation and recognition.

The machine also incorporates advanced features:

- German Basler high-speed cameras enable full-board photo programming, allowing for remote control and debugging without human intervention.

- The programming mode is revolutionized with panoramic real-life image display, facilitating precise and rapid positioning of MARK points and cutting lines, eliminating the need to manually observe CCD and move XY axes to locate these points.

- Image teaching methods streamline programming by allowing users to simply determine start and end points in the picture, eliminating the need to confirm points one by one, thus making programming faster and more intelligent.

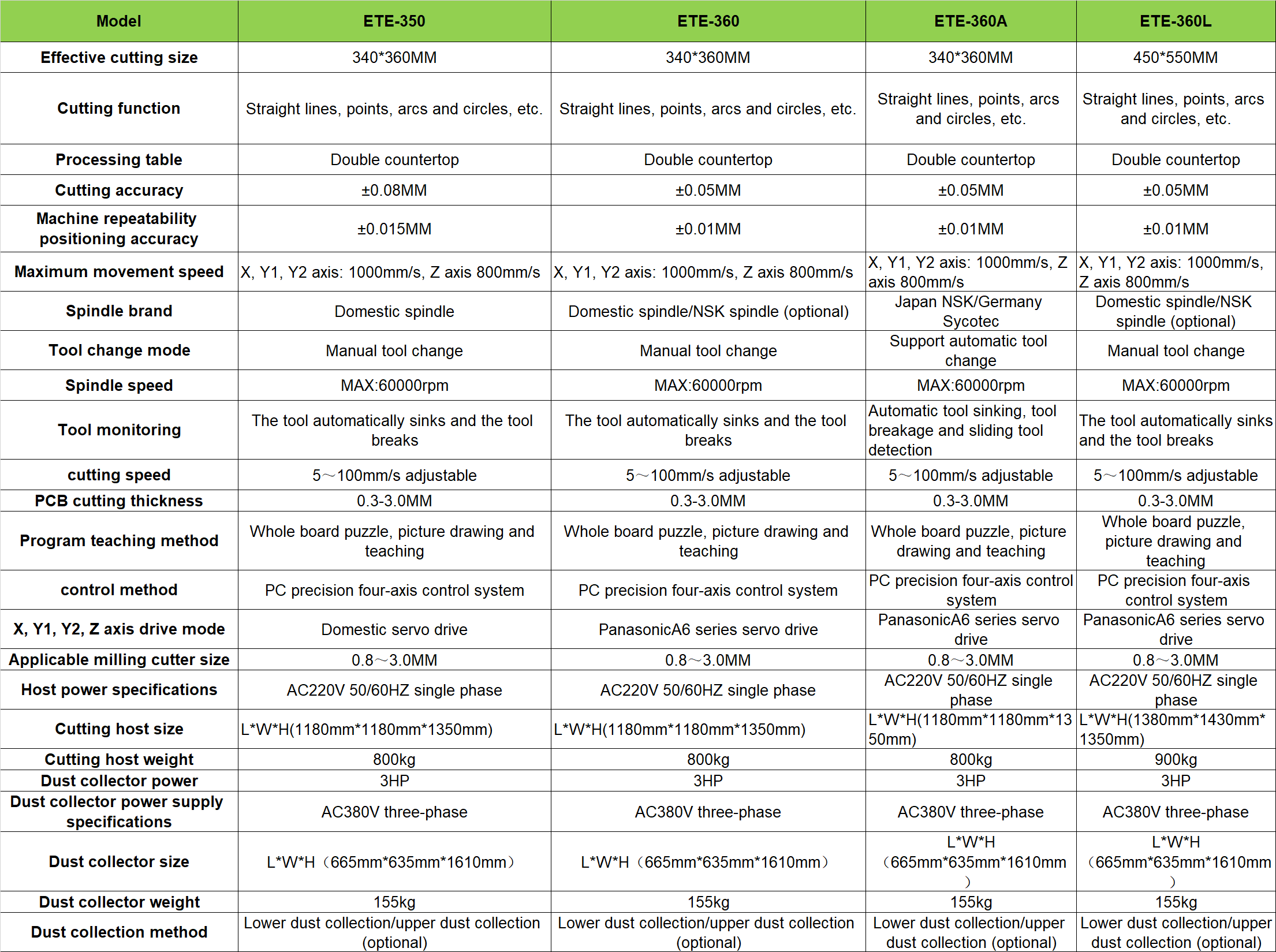

Equipment Specifications: