Resin wave soldering fingers play a crucial role in the efficient transportation of PCB during wave soldering processes. Follow us to know the specifications, common issues, and effective maintenance tips. It is related to resin wave soldering fingers, ensuring optimal performance and longevity.

Specifications of Resin Wave Soldering Fingers

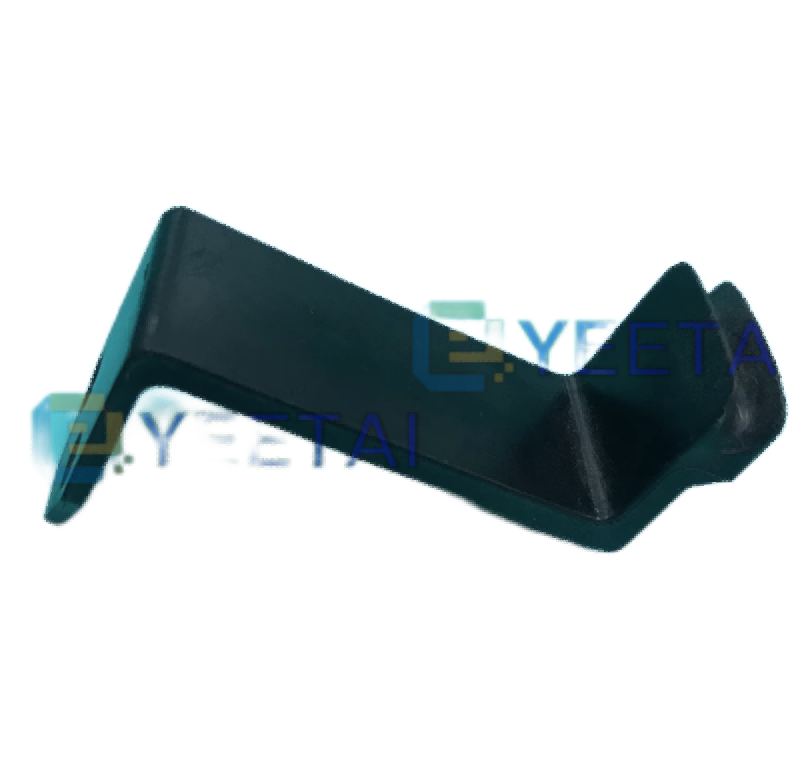

- Material: High-quality resin combined with stainless steel terminals.

- Application: Specifically designed for transporting circuit boards within wave soldering machines.

- Design: Clamping shape that ensures a secure grip on PCBs.

- Customization: Dimensions can be tailored according to customer requirements.

Key Features

- Durability: Constructed from premium resin, providing high hardness and exceptional impact resistance.

- Corrosion Resistance: The resin material effectively prevents rust and corrosion, significantly extending the lifespan of the soldering fingers.

- Ergonomic Design: Formed through multiple plastic processing stages, these soldering fingers offer a superior tactile feel and enhanced toughness.

Understanding Wave Soldering Finger Malfunctions

Despite their durability, resin wave soldering fingers can experience issues that may disrupt the soldering process. Here are common causes for jamming and ways to address them:

- Wear and Tear: Extended usage and uneven wear from replaced chain claws can lead to operational difficulties. Particularly as the number of replacements increases.

- Cloth Entanglement: Cleaning equipment can cause cloth to get caught in the chains. Thus this leads to deformation of the chain claws if excessive force is applied.

- Improper Alignment: Poor parallelism between guide rails can create inconsistent spacing. Causing the chain claws to bind in tighter areas and leading to wear on the rails.

- Incorrect PCB Placement: Misalignment when inserting PCBs can cause localized jamming and deformation of the chain claws.

- Adjustment Oversights: Failing to raise guide rails during wide spacing adjustments can result in chain claws catching on the solder pot.

- Insufficient Clearance: A small gap between chain claw bottoms and the handling table can cause the claws to snag on the table during adjustments, leading to deformation.

Solutions for Enhanced Performance

To mitigate the issues mentioned above and improve the functionality of resin wave soldering fingers, consider the following solutions:

- Segmented Floating Structure: Implement a transport system featuring segmented floating structures with robust supporting profiles to maintain guide rail integrity and prevent PCB drops.

- Reinforced Titanium Claws: Utilize professional-grade, lead-free titanium claws that resist solder adhesion, ensuring extended life and reduced wear. The use of 5mm brass flat strips minimizes friction and noise during operation.

- Automatic Cleaning Mechanism: Equip titanium claws with an automatic cleaning device featuring liquid extraction pumps and industrial brushes, facilitating easy and efficient maintenance.

Central Support System: Consider a stainless steel, arc-shaped support system with adjustable height and position settings to accommodate different board weights and prevent deformation.

How to Replace Fingers in Wave Soldering Systems

Proper maintenance is vital for ensuring the longevity of your resin wave soldering fingers. Follow these steps to replace malfunctioning fingers:

- Remove the Chain Cover: Start by removing the protective cover from the PCB transport device on the guiding rail. Activate the transport switch and wait for the chain claw requiring replacement to reach an accessible position before shutting off the switch.

- Detach the Chain Claw: Lift the pressure plate to disengage the hooks from the positioning holes in the chain claw, allowing for its removal.

- Install the New Chain Claw: Position the new chain claw, then lift the pressure plate to secure the hooks into the designation holes, ensuring a tight fit.

- Reattach the Protective Cover: Finally, reinstall the chain cover to complete the process.

Conclusion

Effective maintenance and timely replacement of resin wave soldering fingers are crucial for optimal wave soldering operations. By addressing common malfunctions and following preventive measures, manufacturers can enhance productivity and ensure the longevity of their equipment. For inquiries about customized solutions or more information on resin wave soldering fingers, feel free to reach out to us.