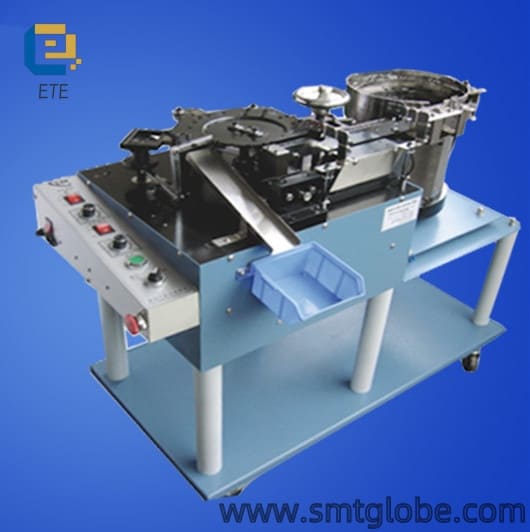

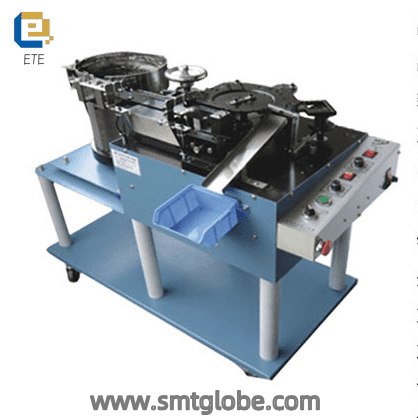

Radial Lead Forming Machine ETE-806: Precision Shaping and Cutting for Electronic Components

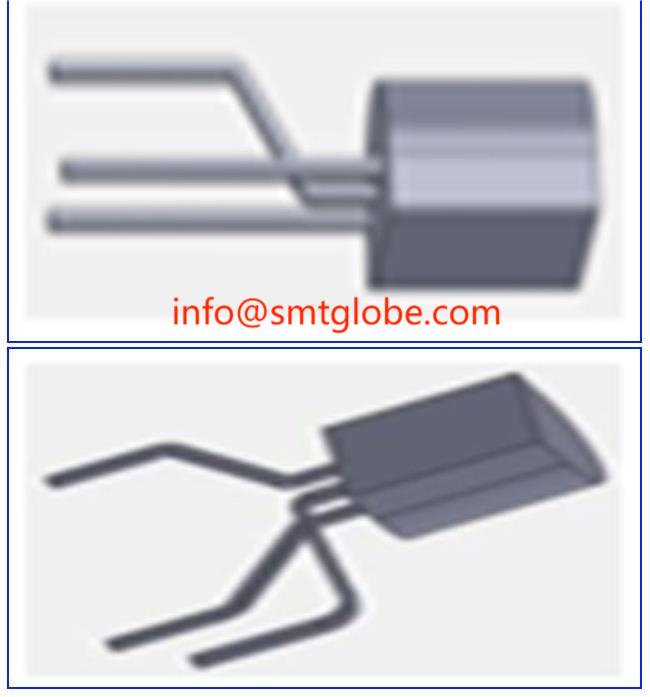

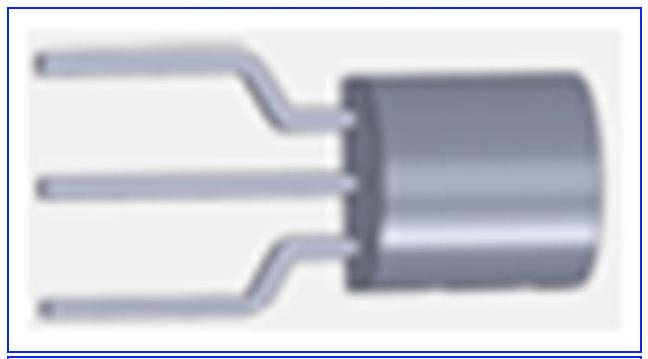

Our radial lead forming machine works for the efficient shaping and cutting of component pins. It provides a reliable solution for manufacturers in the electronics industry. With a compact PLC control system and a fully mechanical structure, this machine delivers precision and high processing efficiency of up to 5,400 pieces per hour. It is ideal for processing various radial lead components, including transistors, integrated circuits (ICs), diodes, and bridge stacks.

Machine Parameters

Product Name: radial lead forming machine

Model: ETE-806

Type: Component Lead Forming Machine

Tool Material: Japanese SKD11

Electrical Components: Omron/Mitsubishi

Power Supply: 220VAC/50HZ

Sheet Metal Process: High-temperature powder coating/surface anodizing/hard chrome

Dimensions: L950xW600xH850mm

Weight: 145Kg Processing Efficiency: 5400pcs/H

Equipment Application: Transistors, ICs, diodes, bridge stacks, and similar radial lead components

Power Supply Voltage: 220 (V)

Feeding Mode: Fully automatic

Lead Length: 3.6 (mm)

Processing Quantity: 4000

Dimensions: 950x600x850 (mm)

Weight: 145 (kg)

Lead forming speed: 5400pcs/H

Key Features of Radial Lead Forming Machine ETE-806

- Fully Mechanical Structure: Designed for durability and consistent performance, the ETE-806 operates with a motor-driven mechanism.

- Compact PLC Control System: The small PLC control system enhances operational efficiency and allows for easy programming and monitoring.

- Disc-Type Structure: The machine features a disc-type structure with precision cam divider positioning, ensuring accurate and reliable operation.

- Automatic Feeding: Equipped with a vibrating disk for automatic feeding, the machine facilitates direct vibration feeding and discharge, streamlining the processing workflow.

- Intelligent Control: Both the feeder and the main machine operation intelligently controlled for optimal performance.

- Quick Mold Replacement: The ETE-806 allows for rapid mold changes, making it a versatile solution for various shaping requirements in electronic component manufacturing.

Advantages of Radial Lead Forming Machine ETE-806

- High Processing Efficiency: Capable of processing up to 5,400 pieces per hour.

- User-Friendly Operation: Simple and easy to operate, suitable for various applications.

- Versatile Applications: Ideal for a wide range of radial lead components, including tube loading power crystals, IGBTs, MOSFETs, and triodes.

Operating Manual

I. Pre-Operation Checks

- Power Supply: Ensure the machine’s power cord is intact and check for any breaks.

- Grounding: Verify that you ground the machine properly for safety.

- Connection Check: Confirm that the power cord connected correctly and that the power supply meets the required voltage (220V).

- Static Electricity: Ensure that the main equipment’s static electricity line is properly connected.

II. Tooling Preparation

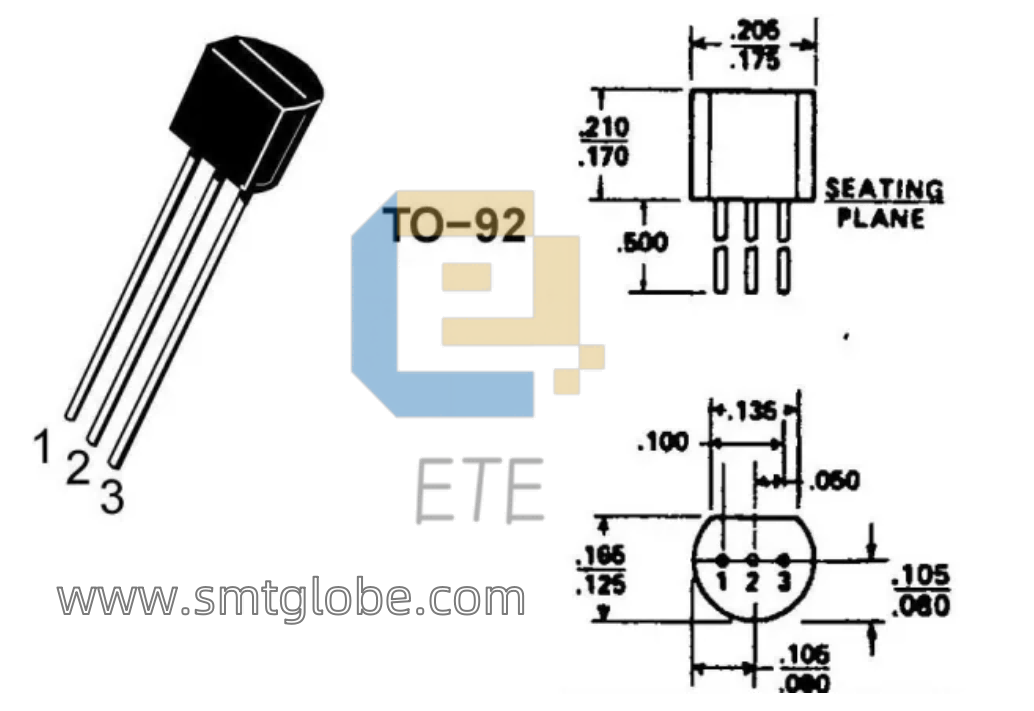

- Component Preparation: Refer to the BOM list for the specific transistor types required (e.g., TL431, S9014).

- Vibration Plate Setup: Adjust the feeding vibration plate’s guide and vibration frequency as needed.

- Feeding Guide Setup: Debug the feeding guide and vibration frequency to ensure optimal operation.

III. Processing Operations

- Start Feeding: Turn on the power switch for the feeding vibration disk to ensure it is operational and check for normal feeding.

- Activate Machine: Turn on the power switch of the radial lead forming machine and ensure that materials transfer smoothly from the vibrating plate to the guide. If not, re-commission as necessary.

- Manual Processing: When the transistor is conveyed to the processing disk, switch to manual mode, press the green start button, and manually process 10 pieces. Insert them into the PCB to check alignment and foot length. If adjustments are needed, notify the engineering department.

- Automatic Mode: Once the sample is verified as qualified, switch the processing mode to automatic for continuous operation.

IV. Shutdown Procedure

- Power Off: When the required quantity is reached, first turn off the vibrating plate power switch, then turn off the power switch of the radial lead forming machine.

- Clean Up: Collect processed triodes and clean the machine, especially any scattered components during processing.

V. Operating Precautions

- Emergency Stop: In case of an emergency, press the emergency stop button and notify engineering staff immediately.

- Machine Use: This equipment is designated for the automatic processing of triodes in a DIP workshop; do not use it for other items.

- Safety During Operation: Avoid placing limbs or body parts near the vibrating device during operation to prevent injury.

- Maintenance Protocol: Always ensure the machine is in a stopped state when changing materials, repairing, or cleaning.

- Electrical Safety: Never perform maintenance work while the machine is running.

- Fixed Modules: The cutting foot and spanning devices are fixed modules; do not attempt to debug or disassemble them unless you are an authorized engineer.

VI. Triode Processing Standards

- Length: 3.4 ± 0.3 mm

Conclusion

The Radial Lead Forming Machine ETE-806 is an essential tool for efficient and precise processing of radial lead components. Its advanced features, user-friendly operation, and high processing capabilities make it a valuable asset for any electronics manufacturing facility. Ensure optimal performance by following the operating manual and safety precautions outlined above.