Capacitor Lead Cutter Former: Automated Precision for Radial Capacitors

The Capacitor Lead Cutter Former is for automated lead cutting and forming specifically for radial capacitors. This advanced machine utilizes a main control board and features a vibrating bowl for automatic material feeding. It employs a robotic arm for various processes, including material handling, shaping, testing, directional sorting, defect sorting, lead cutting, and forming, all performed at designated workstations.

Key Features of Capacitor Lead Cutter Former

- Compact and Portable Design

The entire machine features a compact, integrated structure that is easy to transport. It utilizes a modular mold design for quick and convenient replacements. - User-Friendly Touch Screen Interface

The touch screen human-machine interface is intuitive and easy to navigate, allowing for straightforward parameter settings and operation. - Customizable Forming Options

We can tailor the machine to produce leads of various shapes and sizes according to customer specifications, including:- Long and short leads

- Straight leads

- K leads

- Inside bends

- Outside bends

- 90-degree bends

- Front and back Z shapes

- Wide Applicability

The machine is suitable for capacitors ranging from φ3 to φ10. For sizes larger than φ10, we can customize. - Durable Components

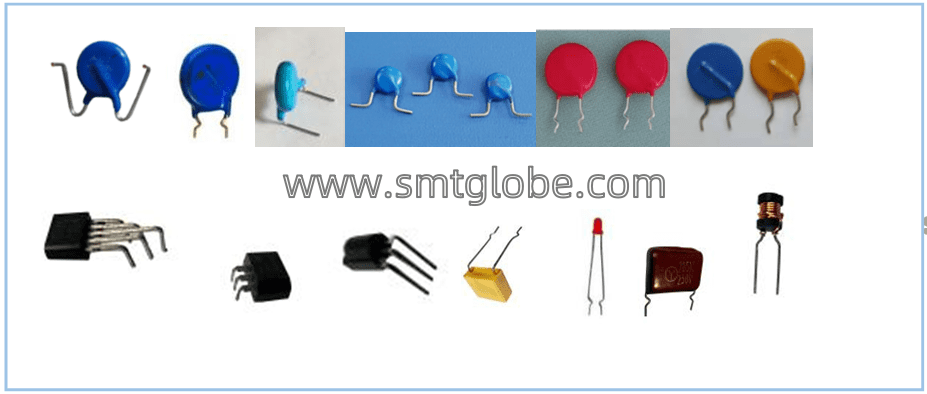

The machine comes with imported CKD cylinders and solenoid valves from Japan, ensuring long-lasting durability. The forming molds and cutting tools are from high-quality Japanese SKD-11 material for precision and longevity. - Versatile Product Compatibility

This machine is ideal for processing various electronic components, including:- Electrolytic capacitors

- Film capacitors

- Safety capacitors

- Inductors

- LED components

- Transistors

- Quartz crystals

Specification

| Cutting and forming Speed | 60-100PSC/Min |

| Power Supply | 220V/50HZ |

| Air Supply | 4—5Kg/cm2 |

| Forming Pitch | 2.5mm 5mm 7.5mm 10mm 15mm 20mm |

| Component Height | 18.5mm –20.5mm |

| Component Lead Length | L=5-17mm |

| Component Package Method | Loose/Bulk |

| Machine Dimension | L1200×W600×H1200 |

| Machine Weight | 350 Kg |

Additional Features of Capacitor Lead Cutter Former

- Automated Material Handling

The vibrating plate automatically supplies materials. Processed through clamping, lead cutting, polarity detection, steering, secondary testing, defect disposal, and forming—all in one continuous operation. - Flexible Customization

The machine can accommodate special requirements by adding corresponding processes as needed. - Quick Mold Replacement

The combined mold design allows for quick and easy replacements. We can adjust each mold group individually. - Stable Clamping Mechanism

The flexible rack and pinion clamps ensure stable material clamping without damaging the components. The design accommodates similar-sized parts without the need to change clamps.

Conclusion

The Capacitor Lead Cutter Former is an essential tool for manufacturers looking to enhance their efficiency and precision in processing radial capacitors and other electronic components. With its advanced automation, customizable options, and user-friendly interface. It meets the diverse needs of modern production environments.