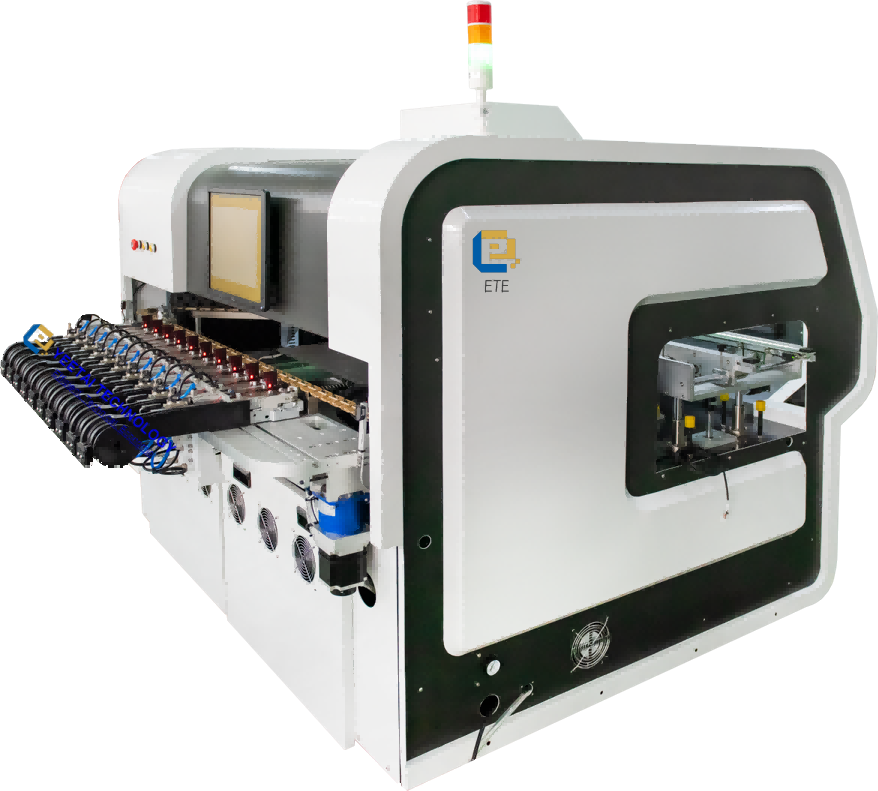

E800A Radial Insertion Machine: High-Speed, High-Precision PCB Assembly

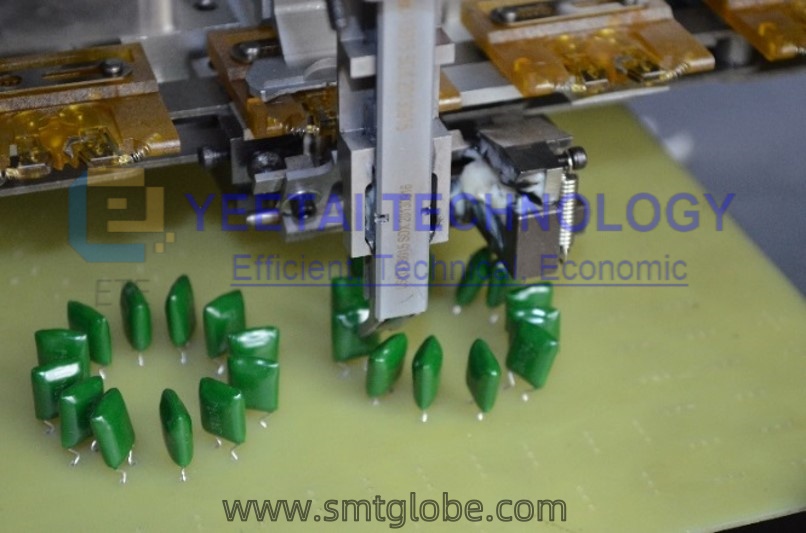

Our E800A Radial Insertion Machine is a cutting-edge, high-speed, high-precision piece of equipment designed for efficient PCB assembly. Developed and produced by our company, this new generation of vertical combined machinery seamlessly integrates automatic loading and unloading systems with radial auto insertion capabilities. The E800A is engineered to arrange various types of radial components (e.g., carbon film resistors, diodes, cylindrical capacitors) in a predefined sequence for precise insertion onto PCBs.

Key Features

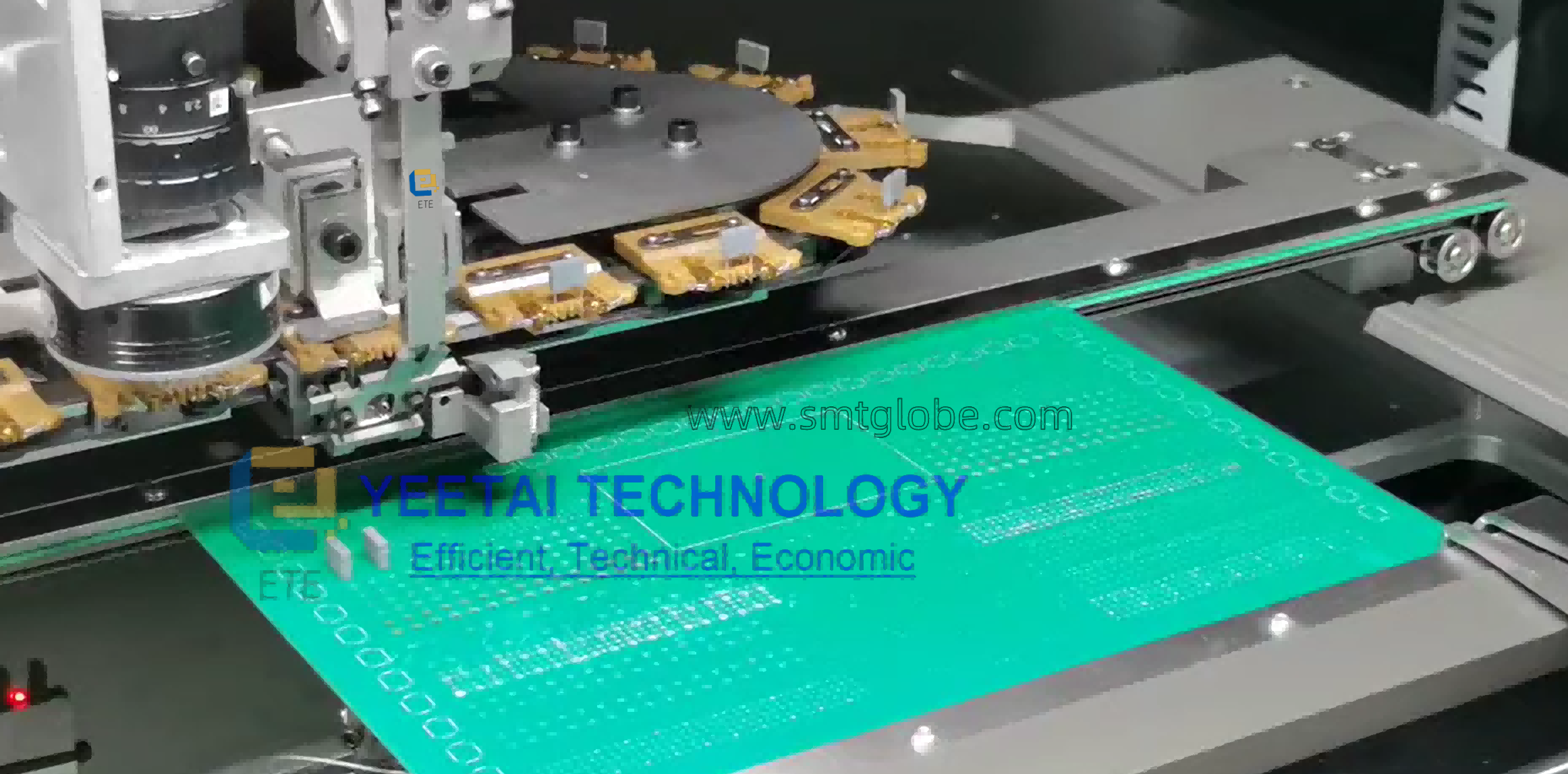

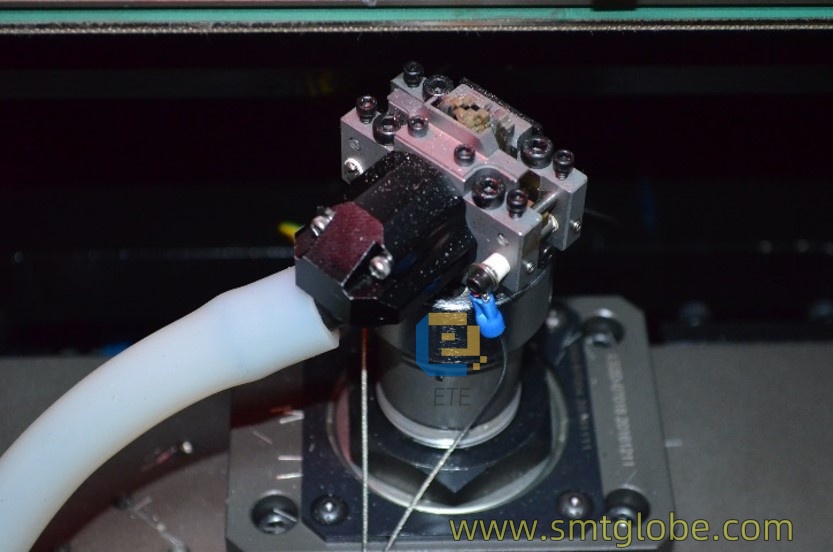

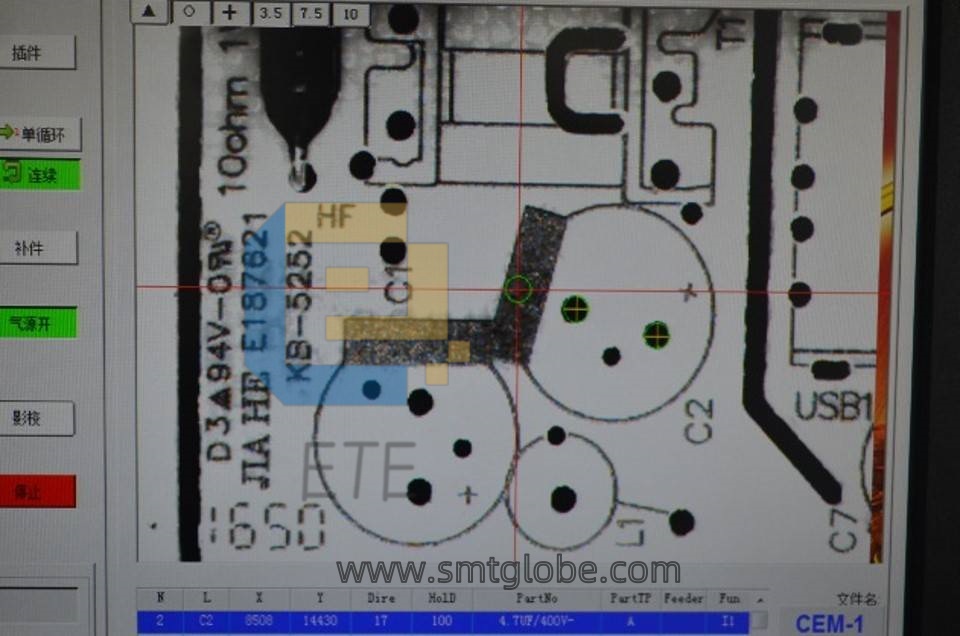

- Precision Auto Insertion: The E800A features a horizontally fixed auto insertion head that leverages X and Y axis movements to achieve accurate placements on the PCB. The angle of insertion is dynamically adjusted through the rotation of the turntable, ensuring optimal component alignment.

- High Throughput: Capable of inserting tape-packaged components at a rate of up to 24,000 components per hour (CPH), the E800A significantly boosts production efficiency compared to manual insertion methods. It handles a diverse array of radial components, including:

- Capacitors

- Transistors

- LEDs

- Key switches

- Resistors

- Connectors

- Coils

- Potentiometers

- Fuse holders

- 360-degree insertion: With a compact, integrated design, the E800A conserves valuable manufacturing space while enhancing operational efficiency. Its 360-degree rotation capability provides flexibility in component insertion, allowing for precise positioning at any angle.

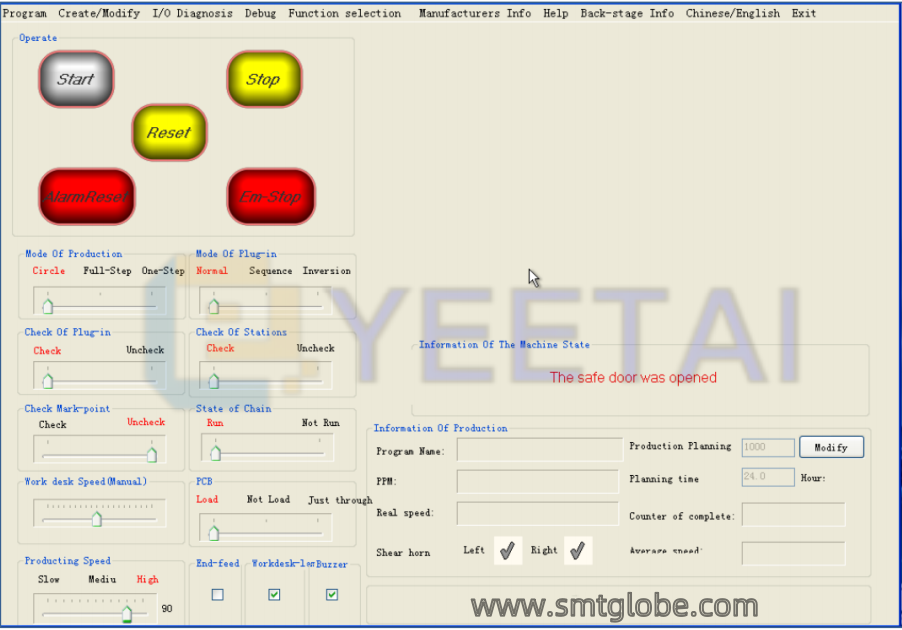

- User-Friendly Interface: The E800A features an intuitive interface based on Windows 10, making it easy for operators to manage insertion processes without the need for complex command codes. This simplicity boosts overall productivity.

- Advanced Servo Control: The machine is equipped with independent servo control systems that guarantee high stability in component insertion performance, achieving excellent results even at high speeds and densities.

- Customizable Operations: The E800A supports programmable height settings for clinching, ensuring that surface mount components are handled reliably and without damage. It accommodates various component sizes with insertion spans ranging from 2.5mm to 10.0mm.

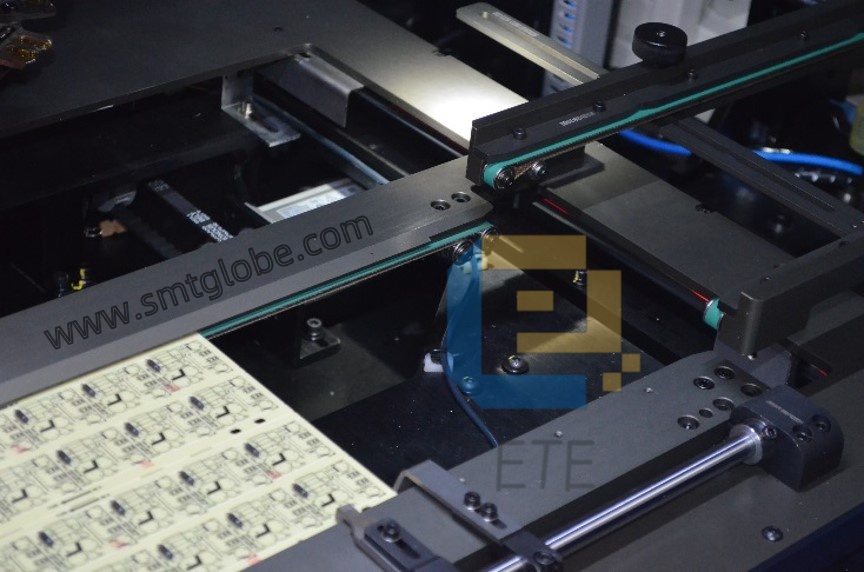

- Automatic PCB Load/Unload: The integrated automatic PCB loading and unloading mechanisms reduce operator dependency, streamlining production in high-volume environments. Customizable feeder quantities and programmable worktable options make it adaptable to varying manufacturing needs.

- Auto-calibration function: The E800A comes equipped with an auto-calibration function. Save time and ensures high precision.

- Production data backup: Reliability and facilitating seamless operation.

Specification

| Machine model | Radial insertion machine E800A |

| Theoretical speed | 24,000 components/hour |

| Insertion direction | 0-360 degrees, 1-degree increment |

| Lead Span | Double pitch 2.5mm/5.0mm/7.5mm/3.0mm/3.5mm/10mm/15mm selectable |

| PCB Size | Minimum 50*50mm; Maximum 400*400mm |

| PCB Thickness | 0.79-2.36mm |

| Component body height | 22mm |

| Component body diameter | 12mm |

| Component type | capacitors, transistors, transistors, LEDs, key switches, resistors, connectors, coils, potentiometers, fuse holders, fused wires, etc. in radial tape package. |

| Component density | Component body distance not less than 1mm; SMD and through hole distance not less than 3mm |

| Component Lead Angle | 5-35 degrees (adjustable) |

| Feeder station | 10 / 20 stations (selectable) |

| Machine Dimension (L*W*H) | Main machine 1770mm*2078mm*1840mm ; feeding station 1200mm*1000mm*1410mm(20 stations) |

| Machine Weight | Weight of main machine 2100KG |

| Power Supply/Power Used | 220V,Ac(single-phase)50/60Hz,1.5KVA/1.6Kw(energy-saving type) |

| System protection | Built-in (USP) power failure protection power supply |

| Use of air pressure (air consumption) | 0.4-0.6Mpa/0.3 cubic meters/minute (dry gas) |

| Ambient Temperature | 5-25 degrees |

| Machine noise | 65dB |

| Hole correction method | Machine vision system, multi-point MARK vision correction |

| Drive system | AC servo, AC motor |

| Data input method | USB interface input (EXCEL file format) |

| Control system | Chinese operation interface (WINDOWS XP system control platform) LCD monitor |

| Table operation method | Clockwise and counterclockwise |

| PCB loading method | Automatic, from left to right or right to left |

| Monitor (computer) | Front and Rear |

Operation Interface

The operation interface allows easy control of the machine’s functions. Key buttons include:

- Start: Begin the automatic insertion task.

- Stop: Halt all machine operations and enter standby mode.

- Return to Zero: Reset the worktable and turntable to their starting positions—an essential step before operation.

- Alarm Reset: In the event of an automatic insertion error, this function will stop the machine and display relevant error messages. Once resolved, click this button to resume production.

Safety Checks Before Operation

Before operating the E800A, particularly after installation or extended periods of inactivity, conduct the following safety inspections:

- Confirm the power supply meets the specified rated voltage.

- Ensure that the main power supply is connected, fuses are intact, and the circuit breaker is operational.

- Verify proper grounding of the equipment.

- Check for foreign objects in the electric control box and on movable parts.

- Inspect the conveyor and timing belts for secure attachment.

- Ensure that heavy-duty mechanisms (screw rods, slide rails, auto insertion shafts) are connected.

- Manually check the movement of X, Y, H, W, L, and J mechanisms for smooth operation.

- Confirm that limit detection and limit mechanisms are correctly positioned.

- Verify the status of the emergency switch, ensuring it is not depressed, and that the main air source and power switch are in the OFF position.

- Check all wiring plugs and air pipes between the computer, the electric control box, and main and auxiliary units for secure connections.

For more information or to request a user manual, please contact us or refer to the additional articles below.

If you need more other insertion machines, welcome to our website or click below.