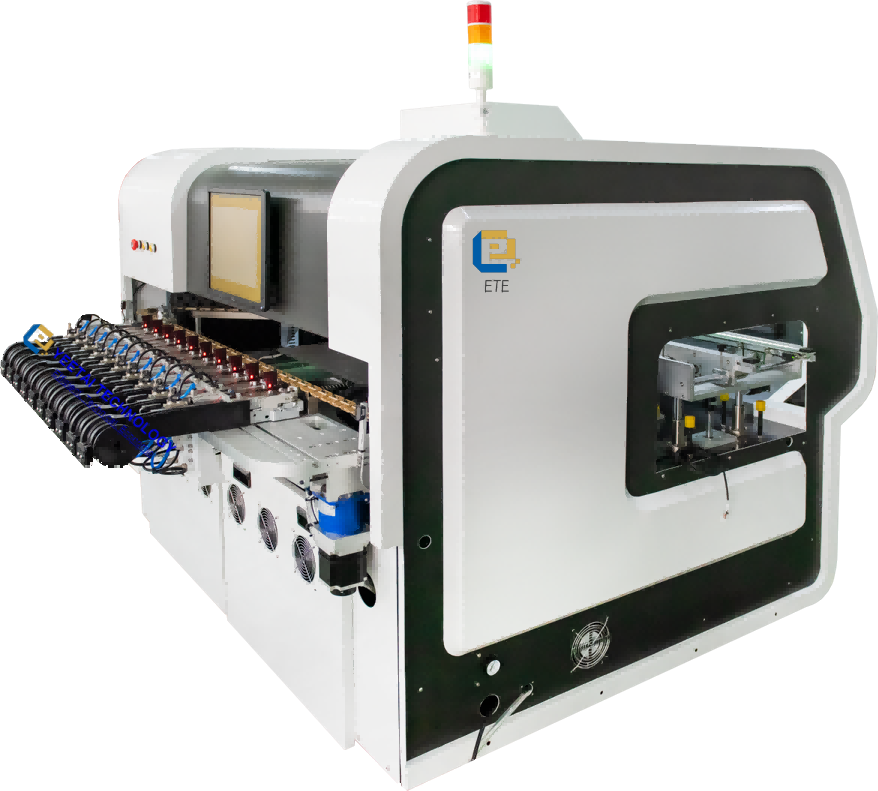

Our E800A is an inline radial component insertion machine that automatically insert tape-packed components onto the PCB. It provides automatic PCB transfer and automatically inserts components supplied on tape into printed circuit boards (PCBs).

Brief Introduction

Our radial component insertion machine features independent sets of servo control systems that ensure high stability in component insertion performance, achieving perfect results at high speeds and densities. Its application software is based on the Windows 10 system, with a simple and user-friendly interface that facilitates human-machine interaction. The machine enhances efficiency in component insertion and the quality of PCBA products.

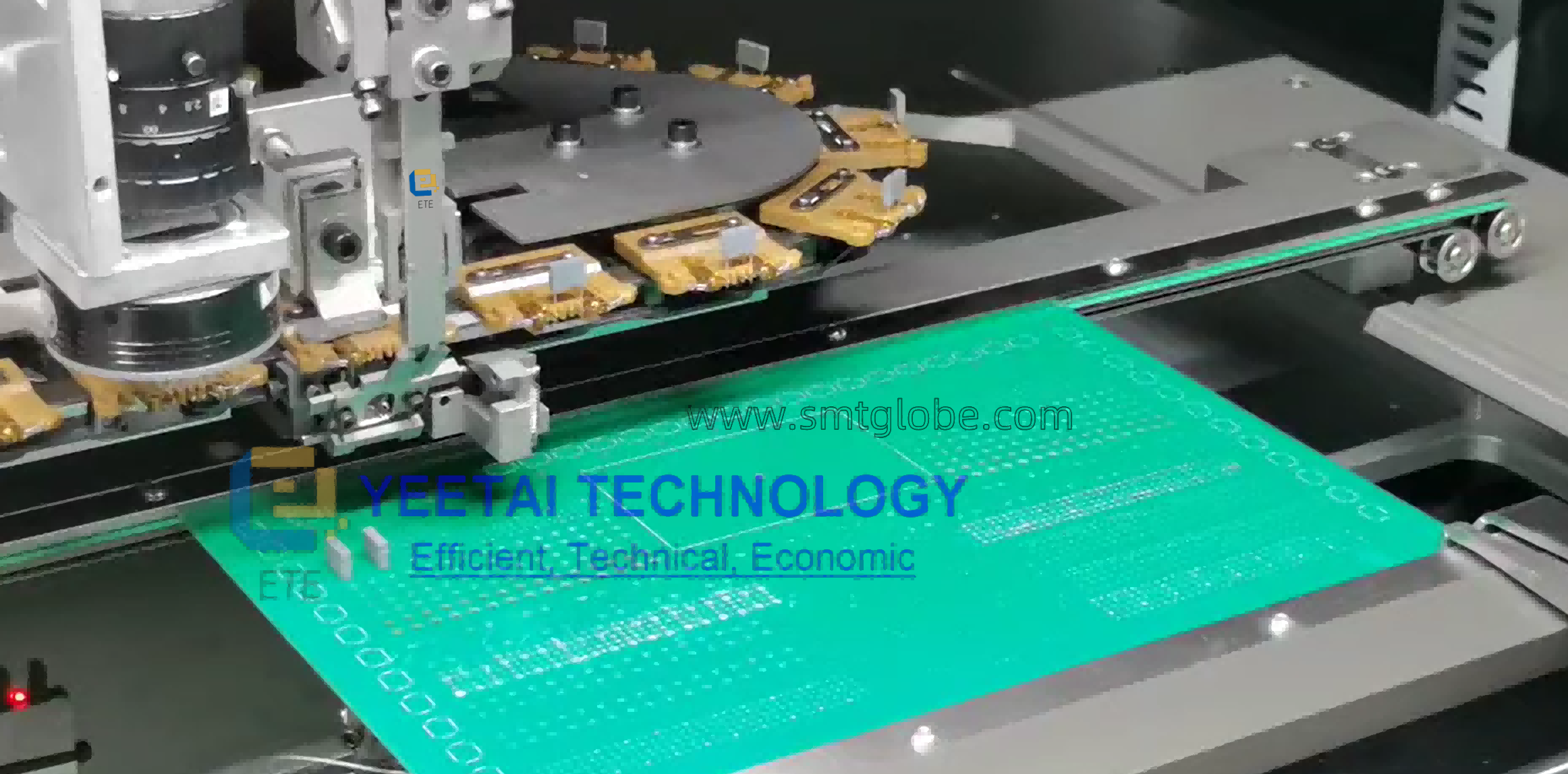

The radial component machine E800A brings a new level of productivity to radial component sequencing and insertion, offering consistently high throughput regardless of component type. It addresses a full range of radial component insertion, including capacitors, transistors, transistors, LEDs, key switches, resistors, connectors, coils, potentiometers, fuse holders, fused wires, etc. in radial tape package. Besides, it automates the insertion of tape-packaged radial components faster, with a CPH up to 24,000, and more reliably than manual processes.

Specification

| Machine model | Radial component insertion machine |

| Theoretical speed | 24,000 components/hour |

| Insertion direction | 0-360 degrees, 1-degree increment |

| Lead Span | Double pitch 2.5mm/5.0mm/7.5mm/3.0mm/3.5mm/10mm/15mm selectable |

| PCB Size | Minimum 50*50mm; Maximum 400*400mm |

| PCB Thickness | 0.79-2.36mm |

| Component body height | 22mm |

| Component body diameter | 12mm |

| Component type | capacitors, transistors, transistors, LEDs, key switches, resistors, connectors, coils, potentiometers, fuse holders, fused wires, etc. in radial tape package. |

| Component density | Component body distance not less than 1mm; SMD and through hole distance not less than 3mm |

| Component Lead Angle | 5-35 degrees (adjustable) |

| Feeder station | 10 / 20 stations (selectable) |

| Machine Dimension (L*W*H) | Main machine 1770mm*2078mm*1840mm ; feeding station 1200mm*1000mm*1410mm(20 stations) |

| Machine Weight | Weight of main machine 2100KG |

| Power Supply/Power Used | 220V,Ac(single-phase)50/60Hz,1.5KVA/1.6Kw(energy-saving type) |

| System protection | Built-in (USP) power failure protection power supply |

| Use of air pressure (air consumption) | 0.4-0.6Mpa/0.3 cubic meters/minute (dry gas) |

| Ambient Temperature | 5-25 degrees |

| Machine noise | 65dB |

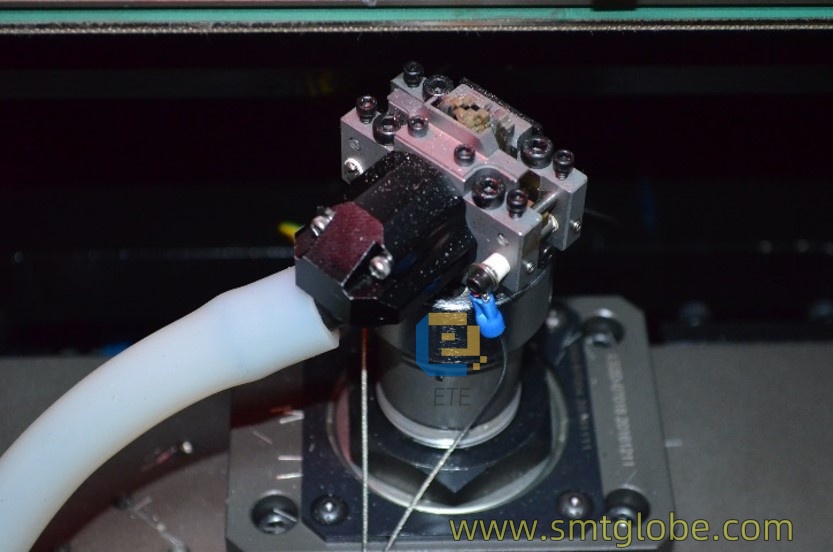

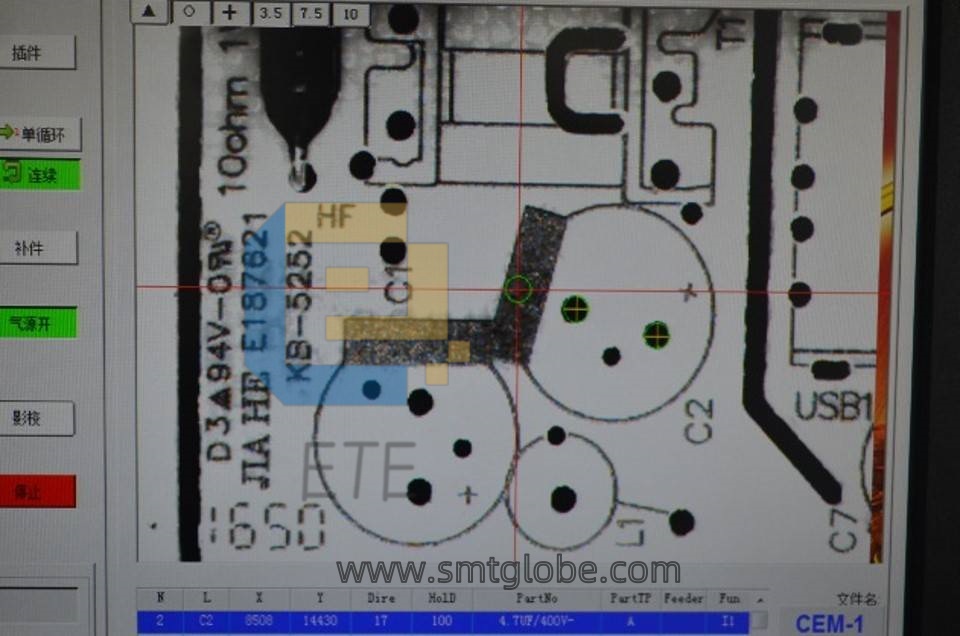

| Hole correction method | Machine vision system, multi-point MARK vision correction |

| Drive system | AC servo, AC motor |

| Data input method | USB interface input (EXCEL file format) |

| Control system | Chinese operation interface (WINDOWS XP system control platform) LCD monitor |

| Table operation method | Clockwise and counterclockwise |

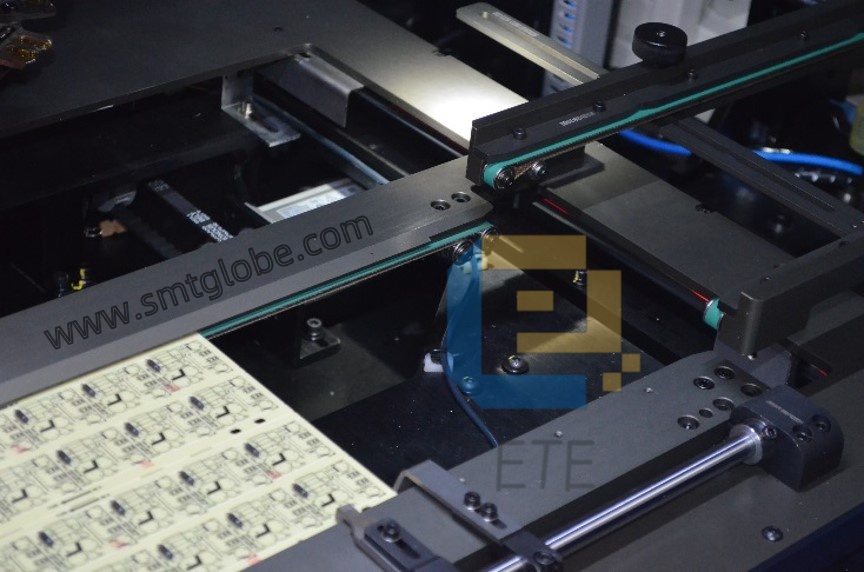

| PCB loading method | Automatic, from left to right or right to left |

| Monitor (computer) | Front and Rear |

Features

The radial component insertion machine boasts an integrated body design that not only enhances operational efficiency but also conserves space, making it a practical choice for various manufacturing environments. With its 360-degree rotation capability, this machine offers unparalleled flexibility in component insertion, allowing for precise positioning at any desired angle. Moreover, its user-friendly interface eliminates the need for intricate command codes, simplifying the operation process and increasing overall productivity.

Equipped with the industry’s highest actual throughput, the radial component insertion machine delivers exceptional performance that sets new standards for efficiency in component insertion processes. Its versatile clinch options, including programmable height settings to safeguard surface mount components, ensure reliable and damage-free operation. Additionally, the machine supports a wide range of insertion spans, from 2.5mm to 10.0mm, accommodating various component sizes with ease and precision.

Designed for optimal functionality, the radial component insertion machine features servo-driven insertion heads that guarantee swift and accurate component placement. Its automatic PCB load/unload mechanism reduces operator dependency in high-volume settings, streamlining production processes and enhancing efficiency. With programmable worktable options and customizable feeder quantities, this machine offers a tailored solution for diverse manufacturing needs, making it a valuable asset in modern production facilities.

If you need more other insertion machines, welcome to our website or click below.