Performance characteristics of pneumatic PCB separator are as below.

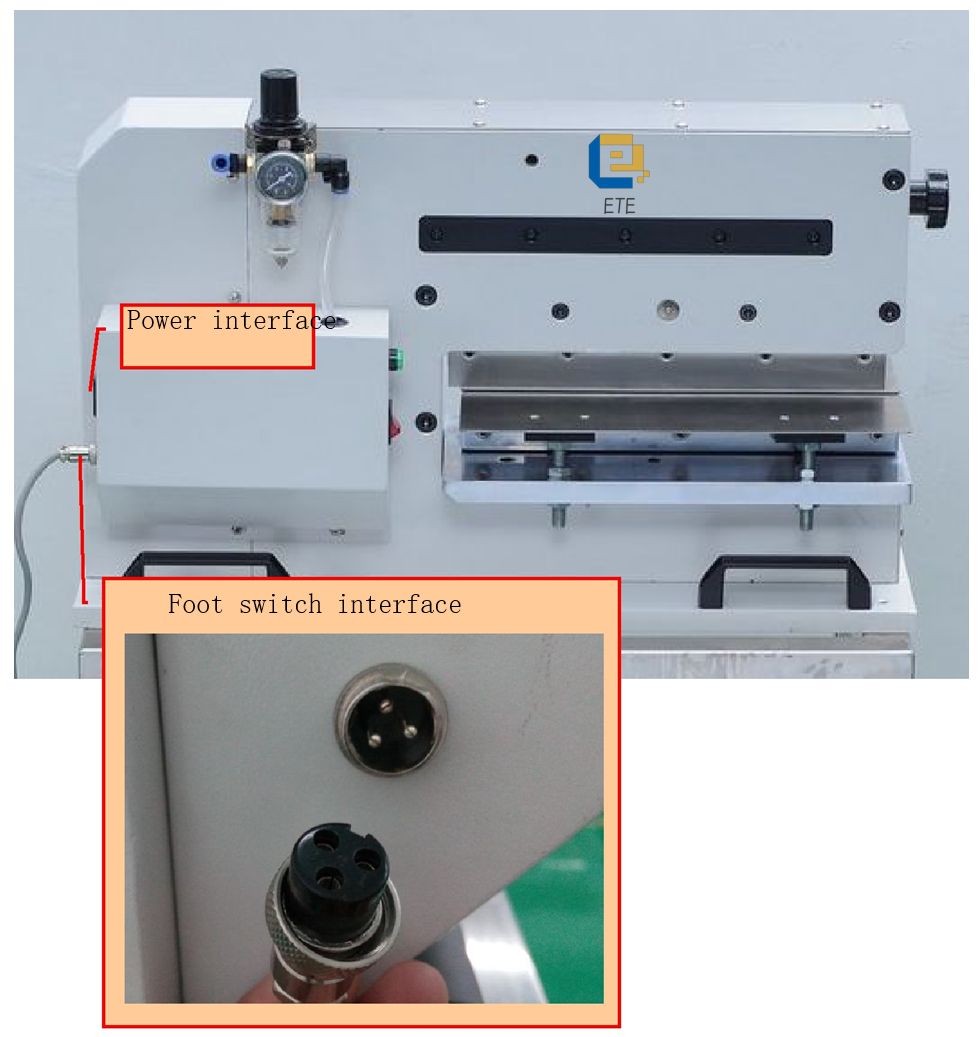

- Cutting rate is 1 second/1 division, controlled by a foot pedal pneumatic switch.

- The cutting blade group is passively started. This allows for safe control of the cutting line and position. With small cutting stress, PCB panel is not prone to cracking.

- Non-roller (wheel blade, walking blade) cutting, no dust, no motor drive, no carbon powder pollution.

- Non-frictional cutting, no residual metal from cutting tools.

- The blade can be used 200,000 times without power supply, hence no electrical product consumption, and no need for replacement.

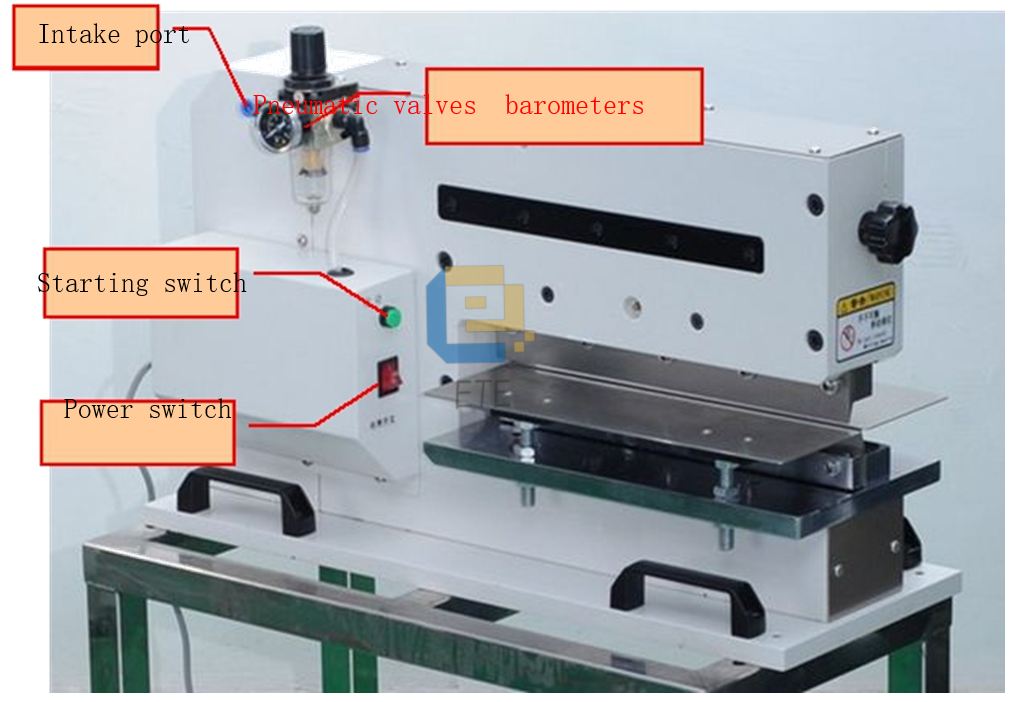

- Uses 4-5KG of air pressure, no specific cutting location required; the appearance can be wiped with rust maintenance oil.

Safety precautions when operating the pneumatic PCB separator

- Before operation, confirm that the machine is functioning properly. Before starting formal work, please make the machine run for about two minutes. This is to check the smooth movement of the cutting tools, circuits, and air paths.

- Strictly follow the operation manual. Non-standard operations will cause safety accidents. Thus,it is important to pay attention to the standard operation when using the pneumatic PCB separator.

- Strengthen safety awareness in industrial production.

- During processing, align the V-groove of the PCB board with the straight blade to minimize burrs and reduce tool wear. Thereby improving efficiency.

- Do not place fingers or other items between the two straight blades during operation. The straight blade is very sharp. Therefore,please keep fingers or other debris at a certain distance from the blade during processing.Safety first!