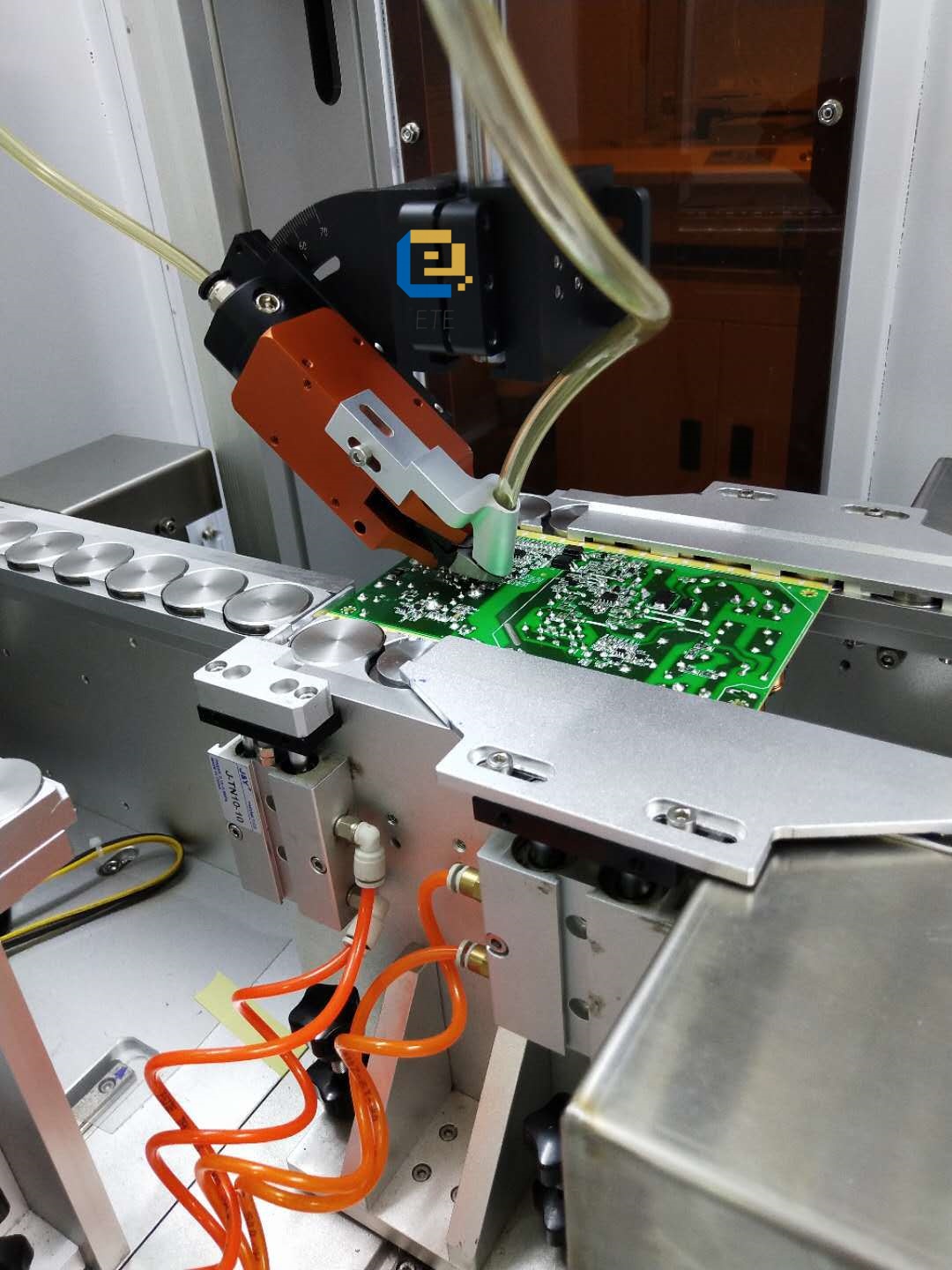

Our PCBA lead cutting machine EF-830A is an inline selective automatic lead cutting machine that effectively addresses lead cutting workstation issues.

Our PCBA lead cutting machine is specifically engineered for the selective trimming of component leads that cannot be easily controlled after soldering in electronic products. This innovative machine effectively cuts and vacuums the trimmed leads into a designated container, significantly enhancing lead cutting efficiency while safeguarding PCBs and electronic components from damage—an assurance that manual cutting cannot provide. By addressing the limitations of manual lead cutting—with its inherent lack of control over lead lengths—this advanced solution reduces labor costs, boosts productivity, and improves overall quality.

Key Features

High-Efficiency Operation

Operating at a power of 700W, the PCBA lead cutting machine is designed for optimal efficiency and precision in electronic manufacturing.

Automated Path Following and Waste Management

A standout feature of this machine is its ability to automatically follow a pre-programmed path, cutting and vacuuming each lead individually. The length of each cut can be controlled independently, while waste leads are collected automatically, eliminating the need for manual intervention.

Seamless Integration as an Inline Machine

This machine operates as an integral part of the production line, allowing for smooth communication with other machinery. It facilitates automatic PCB loading and unloading, ensuring a continuous workflow into the working area for autonomous lead cutting.

Customizable Cutting Settings

The PCBA lead cutting machine offers adjustable lead cutting speeds and individual point cutting settings, allowing customization to meet specific production needs. Utilizing advanced fiber optic sensors for precise positioning, it achieves an accuracy of up to ±0.01mm, ensuring consistent and accurate results.

Precision Control with Stepper Motors

Featuring high-precision stepper motors, this machine delivers precise lead cutting trajectories, adhering to the highest quality standards in the industry. Its track is equipped with universal fixtures, eliminating the need for separate fixture development and simplifying line changes for different products.

Versatile Cutting Capabilities

The machine is capable of cutting leads in various shapes, including spatial points, lines, arcs, and more. Its adjustable cutting head can operate at any angle and direction, providing the flexibility necessary for a diverse range of cutting requirements.

Specification

Applicable PCBA

PCBA MAX:X=250MM,Y=360MM Process edge size MIN:D=3MM

(If there is no process edge must be added jig) PCB board thickness: B = 0.8 ~ 2.5MM

Parts foot length: A <6MM (not cut feet before) parts body height: C <110MM

Cut the foot length of the shortest 0.5MM parts foot diameter <1.6MM

| Model | PCBA lead cutting machine EF-830A |

| Rack size L*w*H | 1250*800*1700mm |

| Equipment platform | T20 mm steel plate ground flat chrome plated |

| Machine travel X-axis | 400 |

| Y-axis of machine travel | 280 |

| Z-axis of machine travel | 100 |

| R-axis of machine travel | 360° |

| U-axis of machine travel | 90° (manual) |

| Guide rail travel | 1250mm |

| PCBA Size Range | 20*50mm~200*360mm |

| PCBA part and wire height | Max.110mm |

| Home direction | Left (Flow direction: Left origin: Right a left) |

| Repeatability | 0.02mm |

| Table load | 5kg |

| Z-bearing load | 3kg |

| Motion stage motor | Closed-loop motor + stepping drive |

| Equipment power supply | AC220V 50HZ |

| Equipment air source | 0.6Mpa/6kg/cm2 |

| Rated power | 750W |

| Drive power | Voltage: 24V SDC Current: 3.5A(MAX)/Axis |

| Cutting capacity | Copper wire, diameter 3mm or less |

| Shear efficiency | 120 points/minute |

| Part foot collection method | Negative pressure suction vessel |

| Safety encoder | Production safety aids (optional) |

| MES system | Connection to production line for data management (optional) |

| Machine weight | 300kg |

In summary, the PCBA lead cutting machine sets a new benchmark in lead cutting technology. By combining efficiency, precision, and versatility, it optimizes the production process and ensures top-notch results in electronic manufacturing. For more information on how this cutting-edge solution can enhance your manufacturing capabilities, please contact us today!