The PCBA component lead cutter is suitable for the post-soldering process of PCB components in various electronic industries where component leads are too long and need to be trimmed. This includes applications in PC power supplies, LED power supplies, industrial power supplies, chargers, control boards, and other PCBA assemblies that require lead trimming.

Key Features

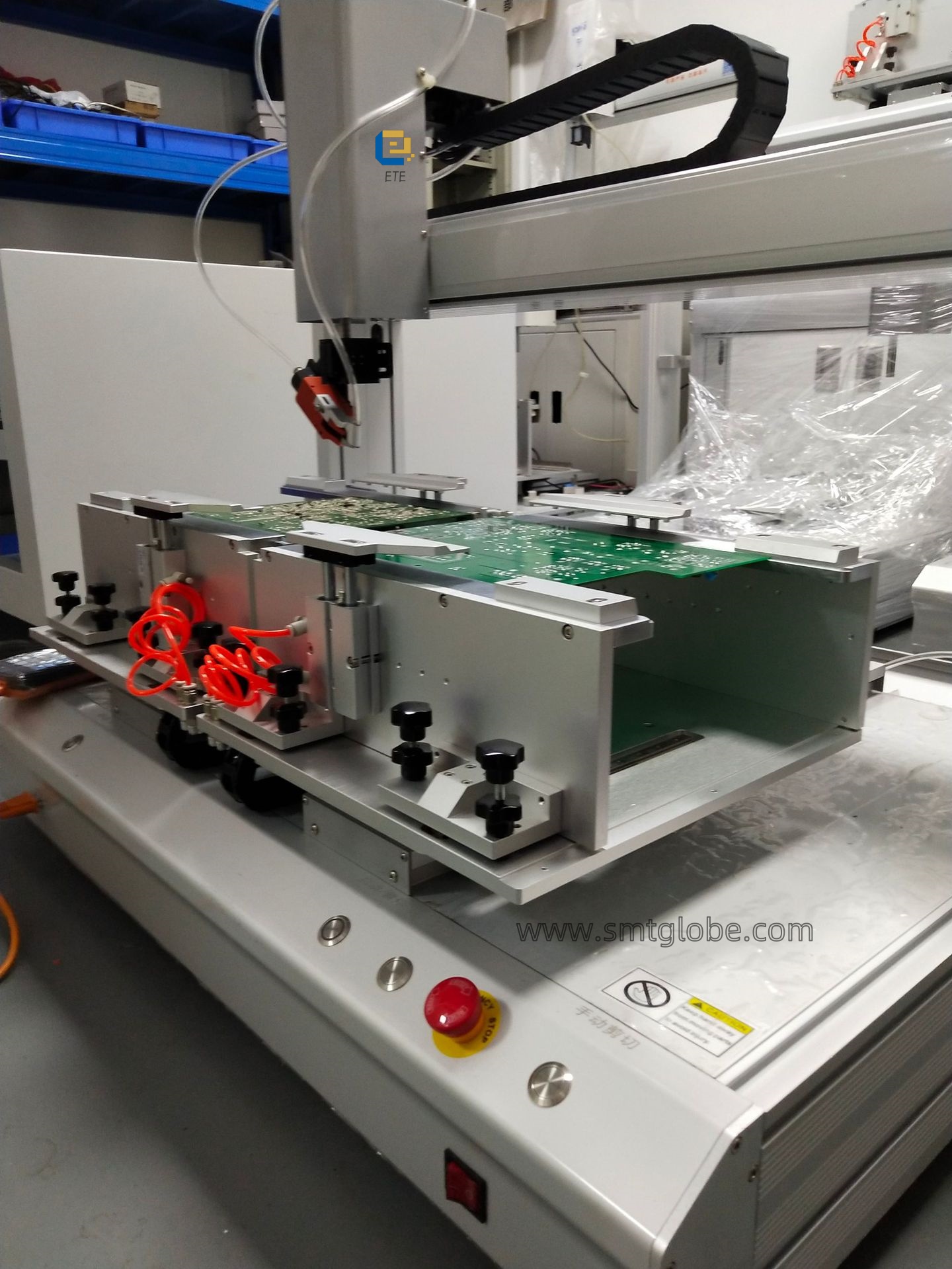

Dual Workstation Design

Our PCBA component lead cutter features two independent workstations, significantly enhancing operational efficiency. This dual design allows for simultaneous processing, greatly reducing production time and costs.

Advanced PCI Control System

Equipped with a user-friendly PCI control system, the lead cutter operates with an intuitive control panel, simplifying the setup and operations for users.

Extensive Document Storage

The handheld control box can store over a thousand processing documents, with each programming file accommodating up to 8,000 instructions. This feature enables operators to quickly access previously saved documents without the need for time-consuming reprogramming during lead trimming.

Effortless Operation

The machine allows for manual switching between left and right workstations, ensuring quick and convenient handling of PCBA boards. With a simple press of the “Start” button following fiber optic sensing, the cutter begins operation, streamlining the workflow.

Enhanced Labor Efficiency

By automating the lead trimming process, the PCBA component lead cutter reduces the pressure on employees, enhancing overall production line efficiency and tackling labor shortages in lead trimming positions.

Precision Cutting Capabilities

Controlled by a high-precision closed-loop motor, the cutter offers adjustable lead trimming speeds and customizable point cutting settings. It can precisely follow any cutting trajectory and trim leads at virtually any angle, catering to a variety of application requirements.

Independent Operation of Workstations

The independent control systems for the left and right workstations enable them to operate concurrently without interference, further boosting productivity and minimizing labor costs.

Specification

| Machine model | EF-630D | EF-A630DS | |

| Machine size | 1040x720x900mm | ||

| Machine movement Stroke | X-axis | 700 | |

| Y-axis | 320 | ||

| Z-axis | 100 | ||

| R-axis | 360° | ||

| U-axis | 90° (manual) | ||

| PCBA Size Range | 20x50mm~200x330mm(Optional 280x330mm) | ||

| PCBA parts and wire height | 110mm (other sizes optional) | ||

| origin direction | Left (optionally right) (Flow: left origin: right → left; right origin: left → right; | ||

| Repeat positioning accuracy (mm) | Synchronous belt drive: 0.02-0.04 | Screw drive: 0.01-0.02 | |

| Work load (table top bearing) | Left: 5kg, Right: 5kg | Left: 8kg, Right: 8kg | |

| Tool load (Z-bearing) | 3kg | 5kg | |

| Drive type | Synchronous belt + guide rail (imported) | Grinding screw + guide rail (imported) | |

| Motion platform camera | Closed-loop stepping motor + stepping drive | Servo motor + servo drive | |

| Power supply | 220V AC/50Hz (optional low voltage 110V power supply) | ||

| Air pressure | 0.6Mpa/6kg/cm2 | ||

| Rated power | 900W(max) | 2000W(max) | |

| Drive Voltage | Voltage: 24V SDC | Voltage: 220V AC | |

| Driving current | Current: 3.5A(Max)/Axis | Current: 6.5A(Max)/Axis | |

| Clamp type | pneumatic scissors | ||

| Cutting capacity | Copper wire diameter Φ0.3mm or less (different wire diameter change different cutter) | ||

| Cutting efficiency | 120 points/minute or more | Above 150 points per minute | |

| Method of extracting part pins | Negative pressure suction vessel | ||

| Safety encoder | Production safety aids (optional) | ||

| MES system | Connection to production line for data management (optional) | ||

| Machine weight | 185kg | 200kg | |

For more information on the PCBA component lead cutter and how it can optimize your manufacturing processes, please don’t hesitate to contact us. Let us help you enhance your production efficiency today!