Offline PCBA Cleaning Machine: Advanced Cleaning Solution for Flux Residues

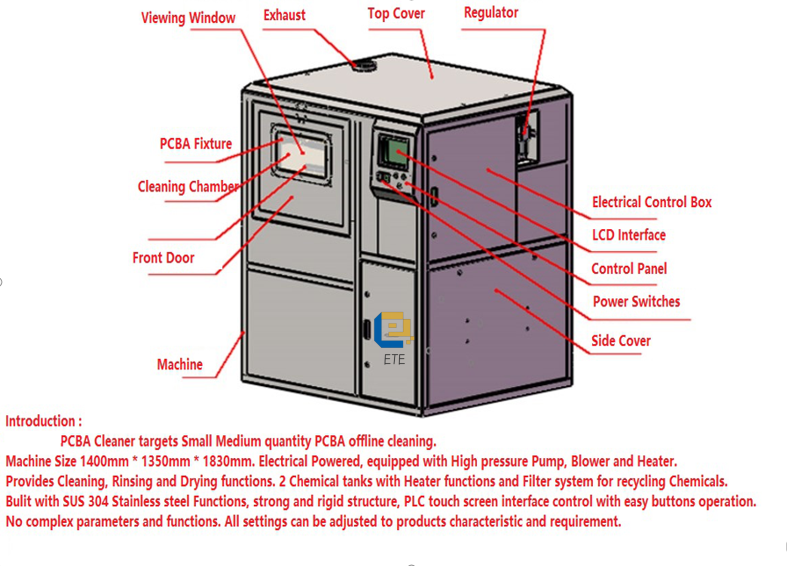

Our Offline PCBA Cleaning Machine is an innovative and efficient cleaning solution designed specifically to tackle flux residues on printed circuit board assemblies (PCBA). This advanced machine is ideal for small to medium production capacities, providing a thorough batch cleaning process that integrates cleaning, rinsing, and drying, all within a single cleaning chamber.

Key Features and Benefits of Offline PCBA Cleaning Machine

- Advanced Control System: The machine is equipped with a Mitsubishi PLC and a Weilin touchscreen control, allowing operators to set various cleaning parameters easily. Customizable settings provide optimal cleaning results based on specific PCBA needs.

- Multi-Stage Cleaning Process: Achieve100% cleanliness with a fully integrated system that effectively cleans, rinses, and dries PCBA. This ensures high quality while reducing environmental impact by utilizing water-based liquids or DI water.

- Safety and Reliability: Features such as automatic alarms and door sensors enhance operator safety, preventing accidental exposure and ensuring safe operation.

- Efficient Design: Made from high-quality SUS304 stainless steel, the machine offers excellent corrosion resistance and durability, while a transparent tempered glass design allows for real-time monitoring of the cleaning process.

- Comprehensive Filtration System: The 0.22μm filtration system effectively removes contaminants such as solder paste and flux from cleaning and DI water discharge, thus maintaining the cleanliness of the environment.

- High-Performance Drying System: A low-noise, high-volume centrifugal fan works in conjunction with heating tubes to significantly enhance drying efficiency.

echnical Specifications of Offline PCBA Cleaning Machine

| Machine Model | ET-5800E | |

| Overall Dimensions | L1180xW1200xH1880 (mm) | |

| Cleaning Chamber Dimensions | L690xW620xH715 (mm) | |

| Cleaning Basket Dimensions | L610xW560xH100 (double-layer design) | |

| Tank Capacities | Cleaning agent tank | 30L |

| Diluent tank | 70L | |

| Spraying tank | 17L-23L | |

| Power Specifications | Temperature Compensation Power | 6KW |

| Solvent Tank Heater | 9KW | |

| Drying Heater | 6KW | |

| Cleaning Method | 360° rotating spray cleaning | |

| Cycle Times | Cleaning | 5-20 minutes |

| Rinsing | 1-2 minutes per cycle | |

| Drying | 20-30 minutes | |

| Water Management | Inlet / Outlet | 1-inch quick-connect interface |

| 1-inch quick-connect interface | ||

| Filtration | 0.22μm for both chemical liquid recovery and DI water discharge | |

Offline PCBA Cleaning Machine Operation Process

- Place the PCBA in the cleaning chamber.

- Set the parameters for cleaning, rinsing, and drying via the touchscreen control.

- Heat the diluent for optimal cleaning temperature.

- Automatically transfer diluent to the spray tank.

- Begin the cleaning process with360° spraying.

- Recover the cleaning agent post-process.

- Execute the rinsing cycle.

- Hot air drying to complete the process.

Conclusion

Investing in our Offline PCBA Cleaning Machine will enhance your production line’s cleanliness and efficiency. With its advanced technology, robust design, and customizable settings, it is your ultimate solution for ensuring PCBAs are free of flux residues and contaminants, thus ultimately improving product quality and reliability.

For more information on how our cleaning solutions can meet your needs, don’t hesitate to reach out!