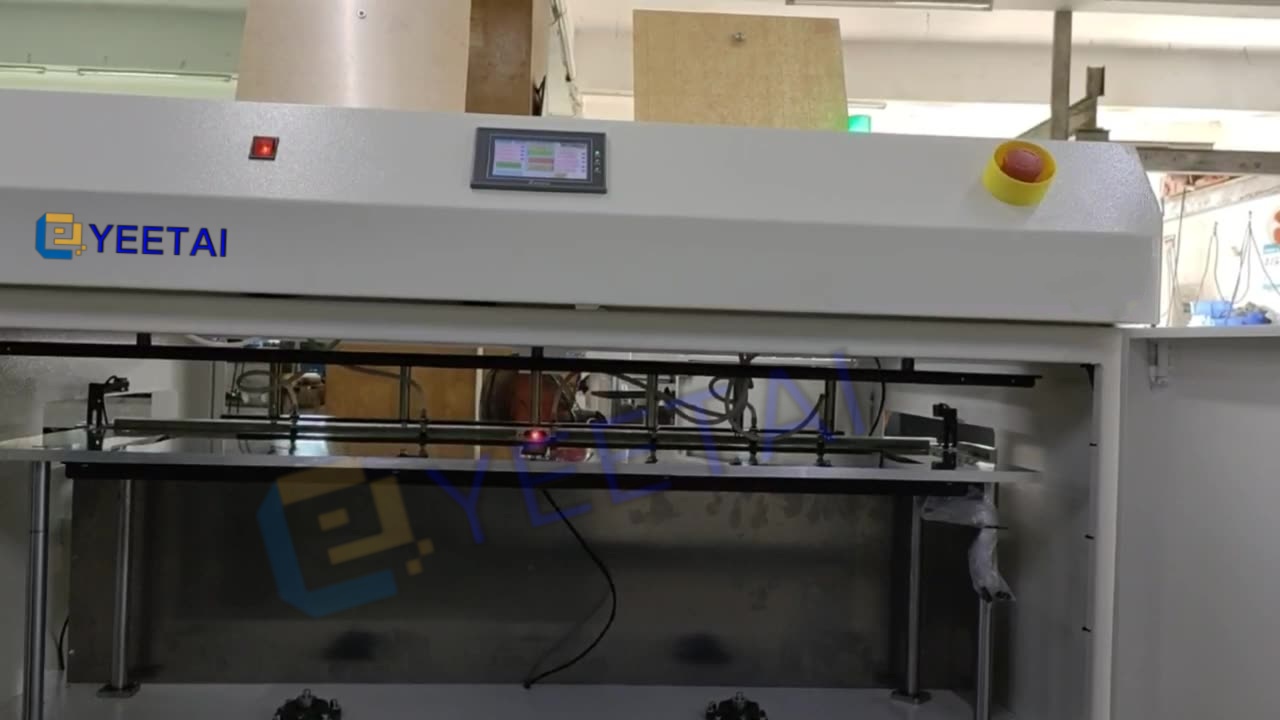

PCB Vacuum Loader: Efficient Loading Solution for SMT and DIP Production Lines

Our PCB Vacuum Loader automatically loads bare PCBs (Printed Circuit Boards) using vacuum technology in both SMT (Surface Mount Technology) and DIP (Dual In-line Package) production lines. This loader minimizes transmission gaps between conveyors. Thus it ensures a seamless assembly process. The PCB Vacuum Loader is located at the beginning of SMT production. It receives signals from the downstream machine and automatically lift stacked PCB boards using vacuum suction. It then transfers the boards onto the conveyor for further processing. This equipment plays a crucial role in streamlining the manufacturing process and maintaining efficient workflow.

Key Features of the PCB Vacuum Loader:

- Enclosed Design: Provides a high level of safety protection with a top safety cover. Thus you can conveniently access hardware for maintenance by opening the cover.

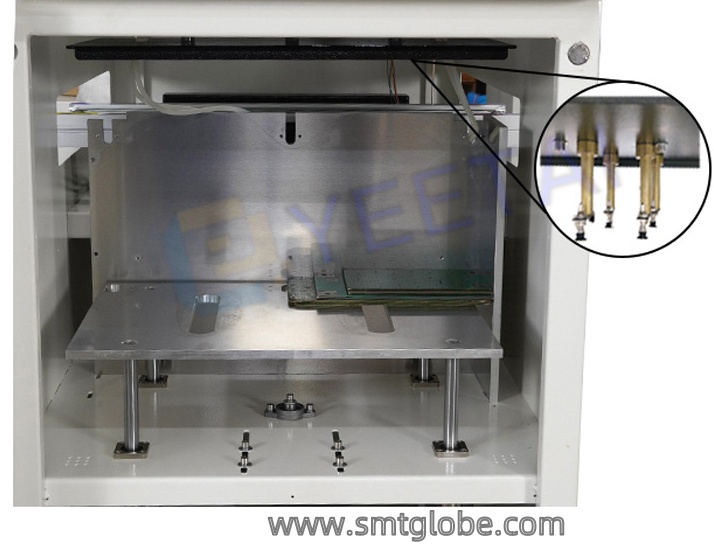

- Powerful Suction Nozzles: Large magnetic suction cups to securely hold and position PCBs, with adjustable positions to ensure stable suction even for boards with small holes.

- Stable Width Adjustment: Includes a sturdy and balanced width adjustment device. The device is controlled by a hand-operated screw mechanism. This ensures precise alignment for different PCB sizes.

- Front Loading Operation: Designed for front loading of PCBs, the loader features an access door with a transparent acrylic panel to monitor internal operations. No need to open the door.

- Large PCB Capacity: Capable of storing up to 220 PCBs with a maximum height of 220mm, accommodating approximately 220 boards with a thickness of 1mm each.

- Compact Footprint: Its smaller machine size allows the PCB Vacuum Loader to occupy minimal floor space. Suitable for various production environments.

- Advanced Control System: Employs a Panasonic PLC control system paired with a user-friendly touchscreen interface and an automatic alarm system for enhanced monitoring.

- Sturdy Frame Structure: Built with a welded sheet metal frame that is finished with paint. And it features a colorful human-machine interface window for easy operation.

- Efficient Lifting Mechanism: Uses a brake motor lifting mechanism with an adjustable step distance. It effectively reduces board loading time. Enabling stacking of up to 300 PCBs (for 0.6mm thick boards).

- Smooth Transfer Structure: Features a stepper motor transfer method with adjustable start and stop speeds for smooth, non-impactful board transfers.

- SMEMA Compatibility: Equipped with standard SMEMA signal ports. The PCB Vacuum Loader ensures seamless online connectivity with other production equipment.

Technical specifications

| Model | Dimension (L*W*H.MM) | PCB size (MM) | Weight (KG) | PCB storage |

| SVL250 | 500*980*1200 | 50*50-445*330 | 130KG | 100~300PCS |

| SVL330 | 550*980*1200 | 50*50-530*460 | 160KG | 100~300PCS |

| SVL390 | 600*980*1200 | 50*50-500*390 | 180KG | 100~300PCS |

| Transmission direction | Front fixed rail guide, left to right or right to left optional |

| PCB board placement position | Place the PCB on the front (convenient to operate) |

| Transmission height | 900mm±20 |

| power supply | 220V\50Hz, 60Hz |

| conveyor motor | Stepper motor 42*48 |

| transfer driver | Stepper driver MT57 |

| Lift motor | LINYI45W with brake function |

| Control System | Panasonic PLC, microcomputer touch screen |

| Detect photoelectricity | Omron or HUAYIFENG |

| Lift screw | Taiwan Shangyin Ball Screw |

| cylinder | Translation lift cylinder Yadek |

| Lift cylinder magnetic sensor | CS1-G magnetic switch |

| PCB detection optical fiber | Matsushita |

| transfer belt | With steel wire timing belt |

| Translation device | Stepper motor and guide rail movement |

| Suction plate device | Large suction vacuum generator, vacuum nozzle (the four nozzle heads can move the suction position arbitrarily) |

Conclusion:

The PCB Vacuum Loader is a vital solution for efficiently loading bare PCBs in SMT and DIP production lines. With its advanced features and design, it streamlines the manufacturing process. It enhances productivity and a reliable workflow.Really an essential addition to any PCB assembly setup

If you need other PCB board handling equipment, we can also help. Find them as below.