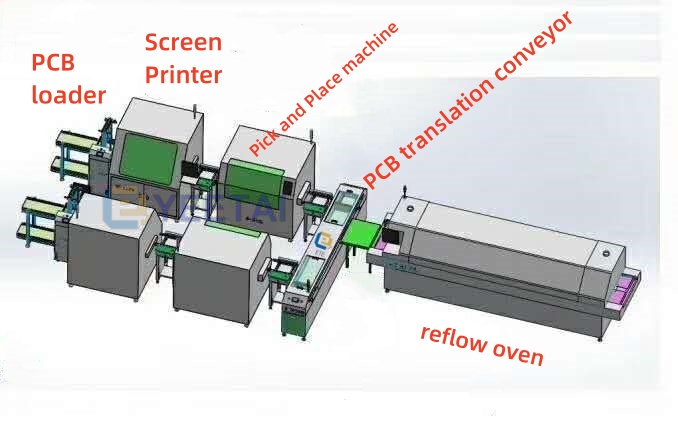

PCB Translation Conveyor: Versatile SMT Equipment for Your Production Line

Our PCB Translation conveyor is a flexible and essential piece of SMT (Surface-Mount Technology) equipment. It effectively redirects the flow of PCBs (Printed Circuit Boards) into different channels within a production line. With various designs and sizes available, it meets different needs and applications. And it can save the cost of one reflow oven.

Common Styles and Sizes of PCB Translation Conveyors:

Single-layer Conveyor:

- This style has a fixed platform with several sliding trays.

- Typical size: 1000mm × 500mm.

- Best for small-scale production lines.

Double-layer Conveyor:

- An upgraded version of the single-layer, it has a second platform for transporting two circuit boards at once.

- Typical size: 1000mm × 1000mm.

- Ideal for medium-scale production lines.

Linear Conveyance:

- Also called “parallel style,” this setup has multiple linked platforms.

- It can be adjusted in length, transporting several circuit boards simultaneously for continuous operation.

- We can customize its size based on your need.

Rotary Conveyance:

- This style uses a rotating mechanism to transfer circuit boards between workstations.

- Typical size: 800mm × 800mm.

- Suitable for production lines that require rotational movement.

Features of the PCB Translation Conveyor:

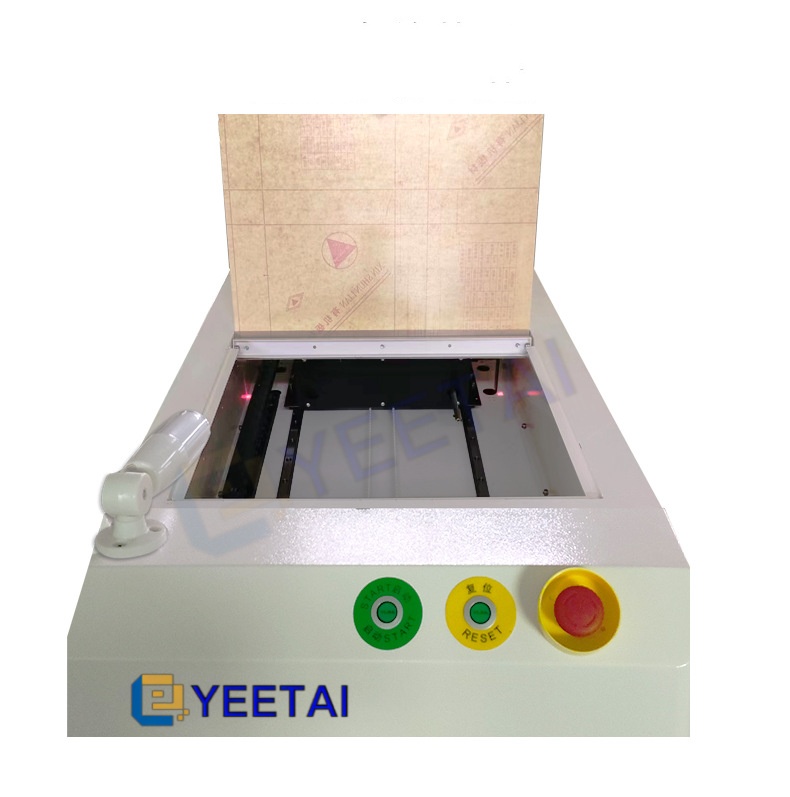

- Reliable Control: Utilizes a Panasonic PLC, imported square photoelectric sensors. And an LEF relay control system for stable operation.

- User-Friendly Interface: Includes a touchscreen display for easy operation, with fault alarms and automatic diagnostics.

- Adjustable Performance: Controlled by a stepper motor, allowing for adjustable speed and distance.

- Safety Design: Enclosed structure for maximum safety, with a top cover that opens for easy maintenance.

- Durable Drive System: Employs an imported steel wire belt drive for precision and longevity.

- Multiple Working Modes: Offers various modes, including check mode and bypass mode.

- Smart Transfer: Adjustable transfer distance that calculates automatically based on PCB width.

- SMEMA Compatibility: Designed to work with the SMEMA interface.

Specification

| Model | Dimension (L*W*H.MM) | PCB size (MM) | Weight (KG) |

| SPD330 | 500*W*1050 | 50*50-330*250 | 140KG |

| SPD460 | 600*W*1050 | 50*50-460*330 | 200KG |

| model | above | ||

| Rack size | 600*1280*1050mm | 600*tailored size*1050mm | 600*1750*900mm |

| PCB board size | 50*50-500*300mm | 50*50*500*300mm | 50*50-535*390mm |

| Machine weight | 250KG | –KG | 300KG |

| Compressed air source | — | — | 5-6kg |

| mobile car | single trolley | Customized multi-car | single trolley |

| power supply | Single phase AC220V 50Hz, 60Hz | ||

| power | 300W | ||

| fixed edge | Anterior fixation (depending on mother body) | ||

| Transport height | 900±20mm | ||

| Transport direction | Left to right (optional right to left) | ||

| Operating mode | Two-in-one, one-in-two (various working modes can be customized) | ||

| Usage environment | No corrosive gas and dust environment | ||

| Anti-interference | Voltage noise: 1000Vp-p, wave width 1us, time 1 minute | ||

| Linear Guides | Taiwan Shangyin linear slide (durable, wear-resistant) | ||

Conclusion

The PCB Translation conveyor is an advanced solution for efficient PCB handling in production lines. It has variety of styles and features. We enhance productivity while ensuring safety and reliability. This equipment is a valuable investment for any SMT production facility.

If you need other PCB board handling equipment, we can also help. Find them as below.