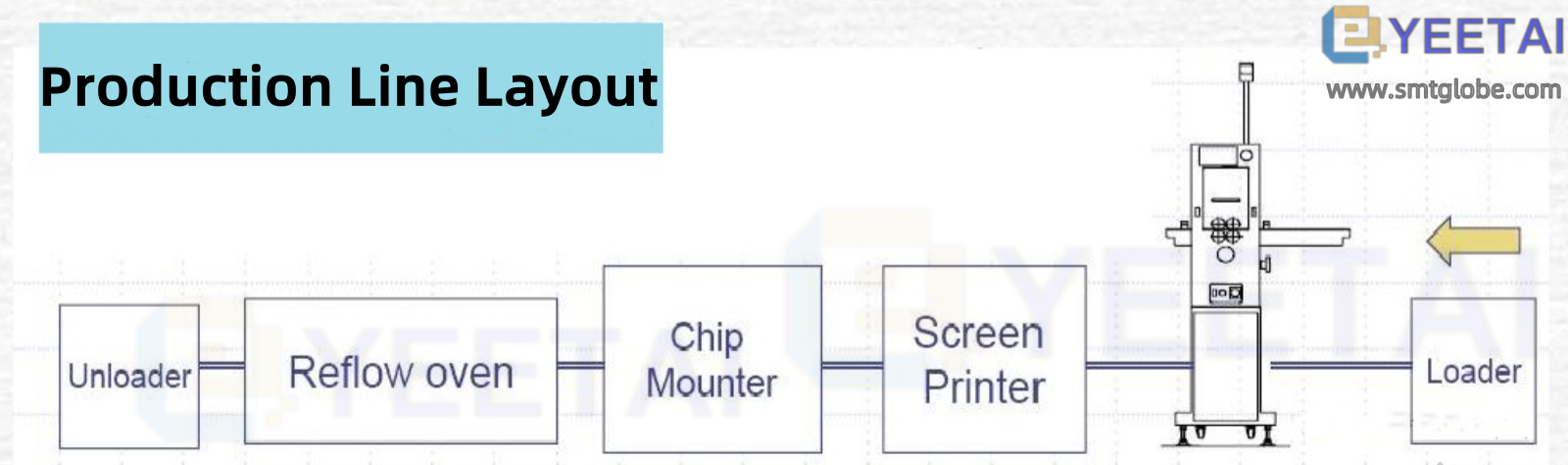

PCB Surface Cleaning Machine: Enhance Your SMT Production Line

Our PCB Surface Cleaning Machine is essential for SMT production lines and coating lines, providing efficient cleaning of PCB pad surfaces before solder paste printing or adhesive coating. By ensuring a clean PCB surface, this machine effectively prevents soldering defects such as cold solder joints, solder voids, warping, and misalignment, significantly improving product quality.

Types of Cleaning Machines We offer machines designed for:

- Single-Sided PCB Cleaning

- Double-Sided PCB Cleaning

Common Methods for removing PCB Surface Contamination

1. Manual Cleaning

- Advantages: Simple and ideal for small-scale production.

- Disadvantages: High labor costs and potential for human error.

2. High-Pressure Air Gun Cleaning

Disadvantages: Wastes energy, generates excessive noise, and causes static electricity buildup.

3. PCB Surface Cleaning Machine

- Advantages: Automated operation, superior cleaning effectiveness, and effective static removal.

- Disadvantages: Higher initial investment cost.

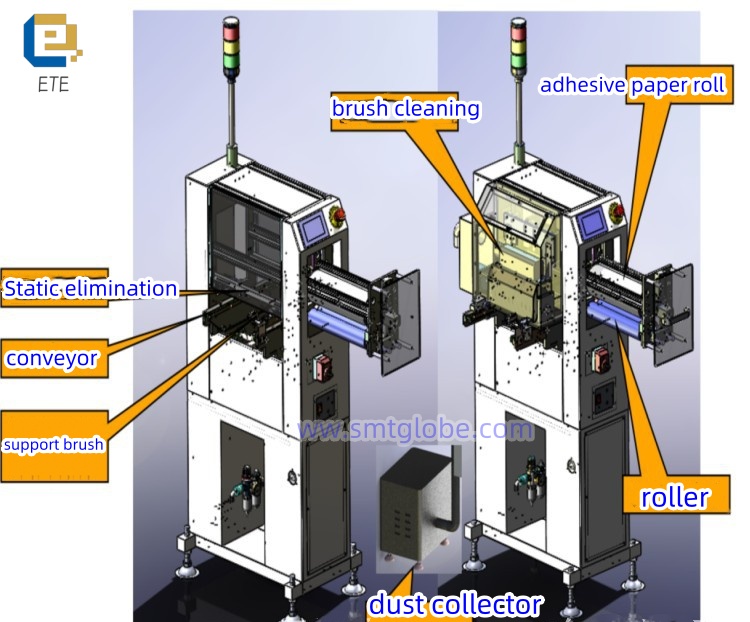

Key Features of Our PCB Surface Cleaning Machine

- Advanced Control System: PLC-controlled with a user-friendly touchscreen interface for easy operation.

- Effective Dust Removal: Equipped with a dust removal roller that eliminates microscopic contaminants.

- Static Elimination Device: Ensures safe operation during production.

- Optional Blackboard Detection: Includes brushes for thorough cleaning.

- Built-In Fault Detection: Features audio-visual alarms for prompt issue resolution.

- SMEMA Compatibility: Standard signal lines for seamless integration with other equipment.

- Modular Design: Allows for easy maintenance and adaptable cleaning options.

- High-Speed Spiral Brushes: Maximizes cleanliness while minimizing adhesive tape waste.

- Enhanced Lifespan: Patent-pending coupling drive structure increases durability.

- Robust Metal Construction: Built with all-metal welding and spray coating for enhanced durability.

Specifications

| Model No | ETE-250C | ETE-350C |

| (L*W*H) Dimensions | L500*W680*H1260(mm) | L550*W950*H1260(mm) |

| PCB Size(L*W)~(L*W) | (50*50)-(350*250)(mm) | (50*50)-(500*350)(mm) |

| Machine Weight | 85KG | 120KG |

| PCB thickness | 0.4~5(mm) | |

| Power supply | 100-230VAC(customized)1ph ,max300VA | |

| Air pressure & consumption | 4-6 bar max 30Lmin | |

| Cleaning sticky roller | Upper *2 | |

| Sticky dust paper | Upper*1 roll | |

| Anti-static device | A set of inlet device and a set of outlet device. | |

| Single side cleaning support | One set of supporting frame | |

| Brush | Anti-static, high density brush | |

| Dust collection group | Dust collect box | |

| Anti-static device | A set of inlet device and a set of outlet device. | |

| Transport height | 900±20(mm)(or customized ) | |

| PCB Transport Direction | Left to rig/right to left (optional) | |

| Speed | 0-9m | |

Conclusion

Investing in our PCB Surface Cleaning Machine not only boosts your production efficiency but also enhances the overall quality of your products by ensuring PCB surface cleanliness.

For more information or to request a quote, please contact us!