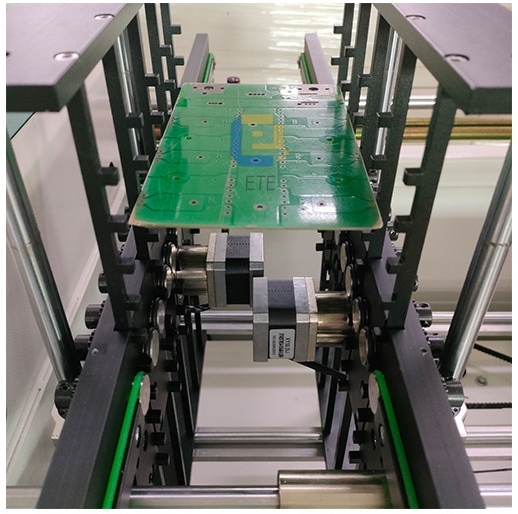

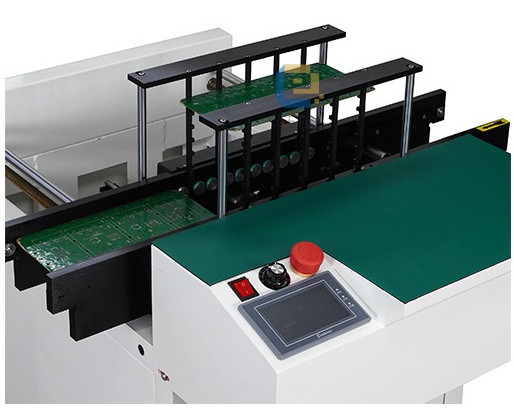

The PCB Reject Conveyor connects SMT and AI production lines, serving as a buffer for PCBs between processes such as inspection, testing, or manual insertion of electronic components. It features dual-screw adjustable track width for precise adjustments. It can be easily integrates with other equipment for signal connection. The conveyor has an anti-static workbench and offers a choice of main frame construction in either iron square tube or aluminum profile. Typically used after inspection devices like SPI/AOI, the PCB Reject Conveyor effectively stores NG (Not Good) PCBs identified by the inspection equipment to prevent them from advancing to the next production step, ensuring that only OK (Good) PCBs flow to subsequent processes.

Features:

- The PCB reject conveyor features high-precision positioning and measurement capabilities, allowing for accurate placement and testing of circuit boards. This enhances product quality and production efficiency.

- It is typically with automation systems that enable functions such as automatic loading, alignment, and ejection. This reduces manual labor, improving production efficiency and stability.

- The conveyor offers various working modes and function selections to accommodate different types and sizes of circuit board rejection requirements. For instance, precise adjustments in the X and Y axes cater to different board dimensions.

- Constructed with high-quality materials and advanced processes, the conveyor boasts a long lifespan and stable performance. Its design and manufacturing reliability ensure efficient and accurate operation in continuous, long-term working environments.

- Equipped with an intuitive human-machine interface, the conveyor is easy to operate. What’s more,users can easily set parameters and commands to achieve precise circuit board rejection and testing.

Specification

| Transport height | 900+50/-20mm, Height adjustable |

| PCB Transport direction | L to R or R to L (customer specify) |

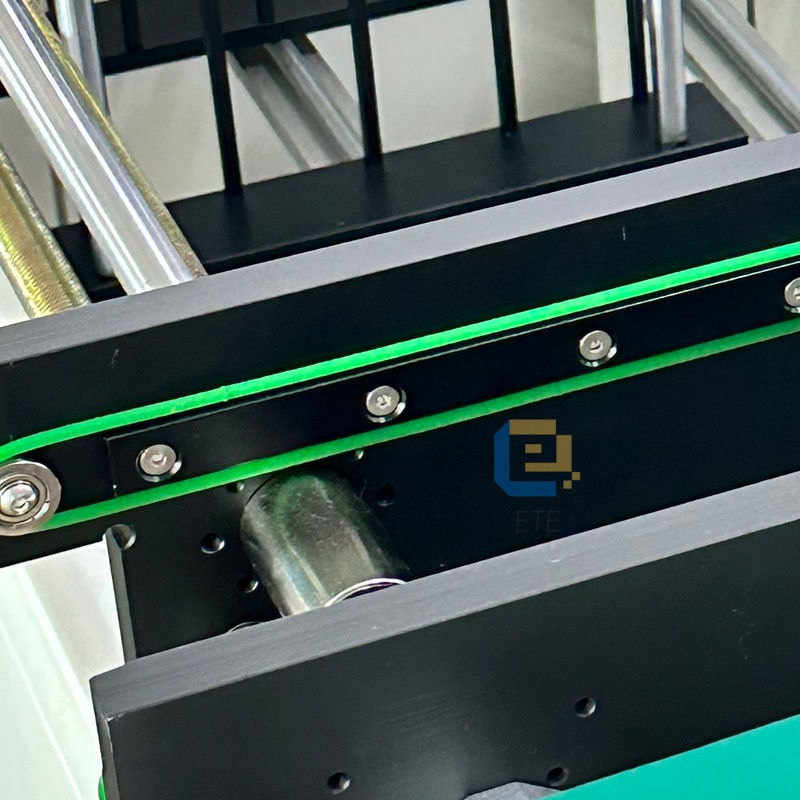

| Transporting rail | Use special guide rails and imported round φ3mm belts |

| transmission motor | 15W speed regulating motor (1 set) |

| Control System | Panasonic PLC |

| Pitch spacing distance | The maximum spacing between each layer is 30MM |

| Storage capacity of NG plates | 10pcs |

| power supply | AC220V/50-60HZ (independent electrical box control) |

| Frame material | Full sheet metal welding, surface using electrostatic powder spraying computer gray |

| standard signal | Using standard four-core signal cable, it can be directly connected to other devices. |