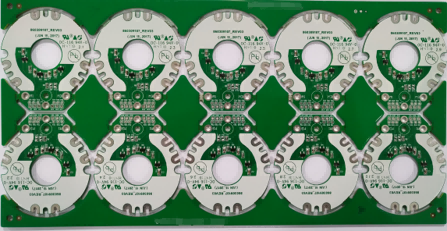

PCB panelization is a crucial strategy in PCB production that involves grouping multiple PCBs onto a single larger panel.

This practice is employed to enhance the efficiency of Surface Mount Technology (SMT) assembly lines. SMT machines used for component placement operate at high speeds, capable of placing several components within a second.

By consolidating PCBs onto a panel, the number of components that can be placed simultaneously is increased, optimizing the utilization of SMT machines and boosting overall production efficiency.

Additionally, PCB panelization saves time by allowing for the simultaneous handling of multiple PCBs, reducing the time wasted on board handling within fixtures.

How to do depanelization?

The introduction of PCB depaneling machines has further streamlined the manufacturing process. These automatic inline depaneling machines are equipped to automatically feed, sense, cut, and sort the finished products without the need for manual intervention, minimizing the risk of quality issues and damage to the products. These machines eliminate the need for 2-3 manual workstations, saving labor costs and training expenses. The software interface of these machines is user-friendly, based on the Windows platform, making it easy to operate and reducing the learning curve for operators. Featuring imported high-speed, high-precision CCD cameras and spindles, these machines ensure stability, reliability, precision cutting, minimal stress on the materials, and high product quality.

For companies looking to implement automated PCB depaneling solutions, there are various options available based on the specific requirements. These options include online depaneling machines capable of differentiating between different types of products and sorting them efficiently. Our company(www.smtglobe.com, info@smtglobe.com) specializes in manufacturing such depaneling machines, designed to cater to different scenarios and production needs. Feel free to reach out to us for more information on our range of depaneling solutions suited for automating PCB separation processes.