The PCB magazine loader is an automatic board loading equipment used for electronic components and PCB boards. It typically consists of a conveying system, positioning system, and board loading mechanical arm.

The working principle involves placing the PCB boards and component materials. The positioning system accurately locates the position of the PCB board. And the board loading mechanical arm retrieves components from the material frame and precisely places them on the PCB board. Say goodbye to manual PCB feeding with this machine. It features selectable pitch settings and automatic magazine change-over. The SMT magazine loader efficiently loads PCBs from the production line to the SMT assembly.

Features of PCB magazine loader

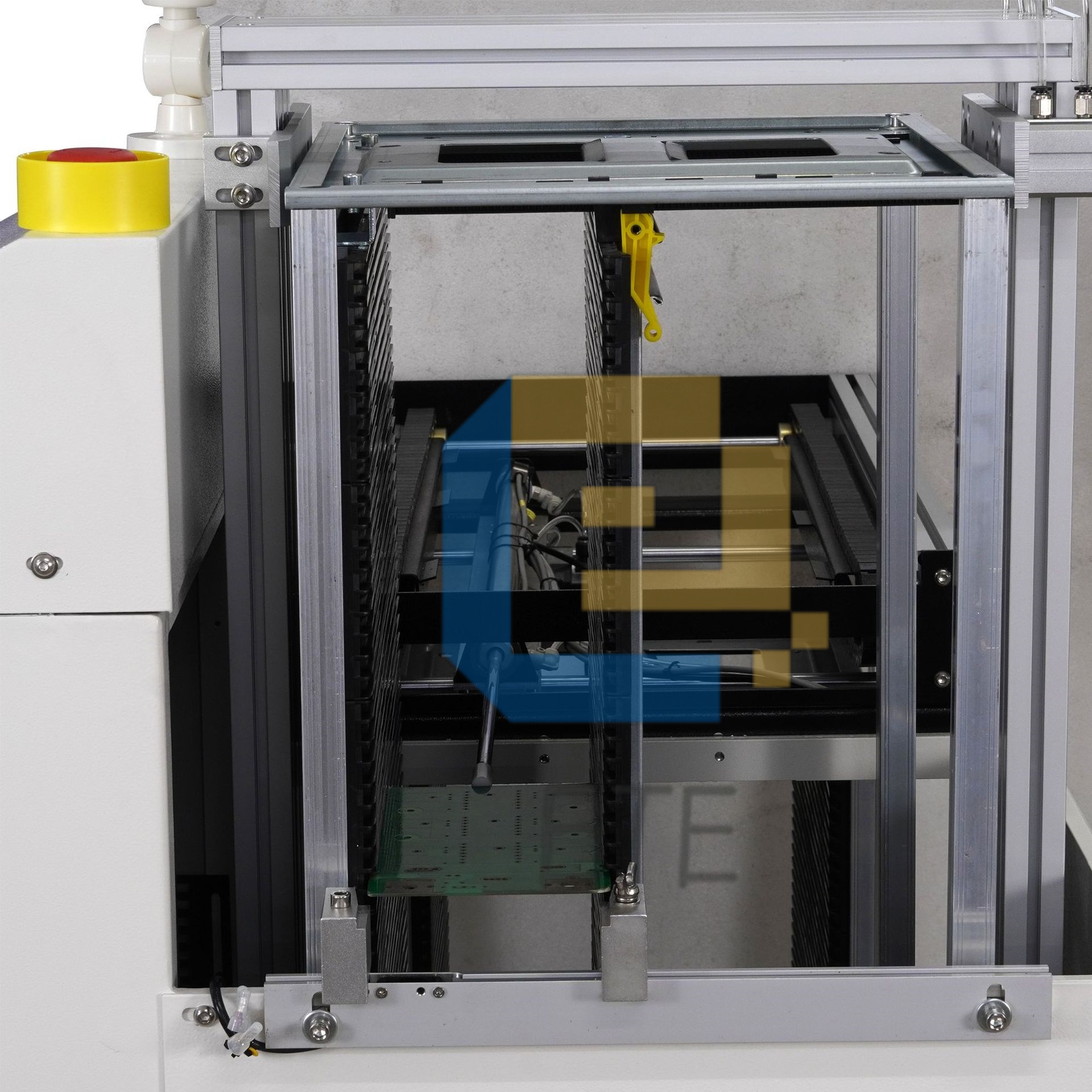

- External structure: PCB magazine loader features a sheet metal structure with an aluminum frame for entry and exit. Its surface coated in white.

- Microcomputer PLC control system ensures stable and reliable operation.

- The sensitive touch screen allows for easy operation, with automatic fault diagnosis function and convenient human-machine interaction.

- Multiple audio-visual alarms and touch screen prompts are available.

- The material frame lifting distance is adjustable according to the height of components on the PCB.

- Automatic counting function facilitates production statistics.

- Special air path design ensures that PCB boards not pushed out of place, enhancing production efficiency.

- PCB magazine loader is compatible with standard SMEMA interface.

- Stepper motor for pushing PCB boards in the docking device.

- Adjustable stepper motor pushing speed, distance, and force, as well as adjustable conveyor belt speed.

Technical specifications

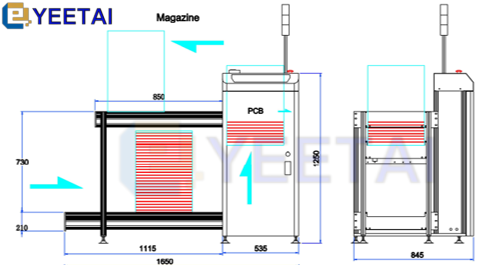

| Model | Dimension (L*W*H.MM) | PCB size (MM) | Weight (KG) | Rack size (L*W*H.MM) |

| ELD250 | 1330*765*1250 | 50*50-330*250 | 140KG | 355*320*563 |

| ELD330 | 1650*845*1250 | 50*50-445*330 | 200KG | 460*400*563 |

| ELD390 | 1800*909*1250 | 50*50-530*390 | 240KG | 535*460*563 |

| ELD460 | 1800*970*1250 | 50×50-530×460 | 300KG | 535*530*563 |

| power supply | Single phase AC220V 50Hz, 60Hz |

| power | 105W |

| Lifting step distance | 10, 20, 30, 40, 50, the step distance can be set arbitrarily |

| Compressed air source | 5-6kg |

| PCB board thickness | 0.6-3.0mm |

| fixed edge | Front fixation (optional rear fixation) |

| Transmission height | 900±20mm |

| Transmission direction | Left to right (optional right to left) |

| Withstand voltage | AC terminal to ground 1500V for 1 minute |

| Usage environment | No corrosive gas and dust environment |

| Anti-interference | Voltage noise: 1000Vp-p, wave width 1us, time 1 minute |