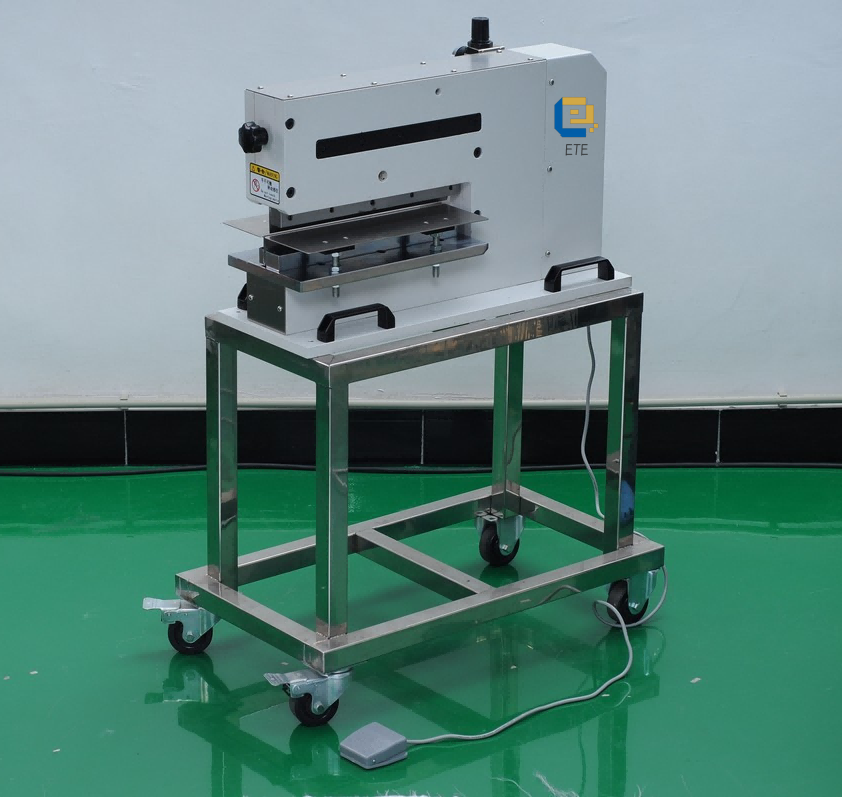

The PCB Depaneling Equipment is cutting-edge and designed for efficient and precise separation of printed circuit boards (PCBs). With its versatile “V” cut guiding device and adjustable cutting blades, this machine can easily adapt to various PCB thicknesses, expanding its utility across different applications. Besides, the use of SKD61 and SKD11 high-speed steel ensures wear resistance and durability, backed by a one-year warranty. The non-roller cutting mechanism eliminates dust and carbon powder pollution, offering a clean and eco-friendly depaneling solution. With a cutting stroke below 1-2mm and a safety-focused design, the PCB Depaneling Equipment guarantees secure and reliable operation. Moreover, its frictionless cutting technology and re-sharpenable blades reduce maintenance costs and enhance longevity. This efficient PCB Depaneler requires minimal power consumption, making it a sustainable and cost-effective solution for PCB manufacturing. Explore the pneumatic PCB Depanelizer, the ideal choice for high-quality and efficient PCB separation.

Features:

- Dual straight blade cutting, especially suitable for dividing precision SMD thin boards and aluminum circuit boards.

- Guillotine cutting method suitable for PCBs of various thicknesses, with a cutting range of 1-2mm, ensuring operational safety.

- Reduces internal stress generated during cutting to below 180uE, avoiding solder cracking and preventing damage to precision components.

- PCB depaneling equipment can cut V-cut edges and component widths as small as 0.3mm, with a height of 70mm.

- Double straight knife cutting, especially suitable for splitting precision SMD thin board, aluminum circuit board.

- guillotine-type work, applicable to a variety of thicknesses of PCB, cutting board stroke in 1-2mm below, no safety concerns on the operation.

- PCB depaneling equipment decreases the internal stress generated when cutting boards to below 180uE, avoiding tin cracks and preventing damage to precision parts.

- PCB depaneling equipment can slit the V groove edge and the width of the parts up to 0.3mm, height of 70mm.

Equipment Specifications:

Maximum depaneling length: 360mm

Dimensions (L×W×H): 700×270×460mm

Depaneling thickness: 0.2-5mm

Operating air pressure: 0.50-0.70Mpa dry air source

Operating voltage: 230VA

Machine weight: 136kg