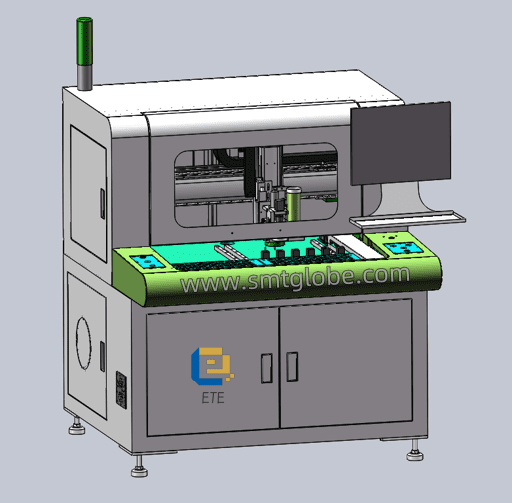

With the rapid development of the electronics manufacturing industry, depaneling machines have become essential production equipment. Among these, the PCB depaneler’s spindle plays a vital role as the key driving component for cutting processes. This article discusses the structure, technologies, and innovations associated with the spindle, highlighting its significance in ensuring efficient and high-quality PCB processing.

Structure of the PCB Depaneler’s Spindle

The PCB depaneler’s spindle consists of several critical components, including the motor, bearings, drive system, and control system. The motor generates power, which is transmitted to the spindle through the drive system. The spindle is supported by bearings, allowing it to maintain stable rotation. The control system precisely regulates the spindle’s speed, feed rate, and position. Overall, the spindle provides the necessary power and precision for cutting, routing, and separating PCB materials.

Key Features of the PCB Depaneler’s Spindle

- High-Speed Drive Technology

The spindle of a PCB depaneler requires high rotational speeds to achieve efficient depaneling and processing. High-speed drive technology encompasses motor selection, optimization of the drive system, and the implementation of effective cooling systems. These elements work together to ensure that the spindle operates stably and reliably, even at high speeds.

- Rigidity and Precision Control Technology

High rigidity and precision are essential for the PCB depaneler’s spindle to guarantee the quality and accuracy of the cutting process. Rigidity control technology involves the design of the spindle structure and the selection of appropriate materials to enhance rigidity and vibration resistance. Precision control technology includes careful selection of bearings, ensuring accuracy in the control system, and implementing compensation measures for vibrations and thermal expansion. This guarantees that the depaneling and processing tasks meet exact specifications.

- Innovative ESD Protection Technology

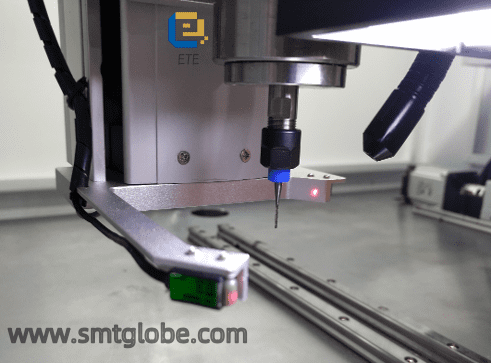

ESD, or electrostatic discharge, refers to the sudden flow of electricity between two electrically charged objects. In the context of PCB depaneling, high-speed spindle operations can generate electrostatic charges due to friction and electrostatic induction. If not controlled, these discharges can damage sensitive electronic components.

To mitigate this risk, incorporating ESD protection technology within the spindle design is essential. During the cutting process, the cutting tool makes sufficient contact with the PCB, allowing any static electricity to be directed into the spindle’s core. Specialized mechanisms within the spindle facilitate the safe transfer of static electricity from the spindle’s core to its outer casing, even during high-speed rotation. Ultimately, this setup channels the static electricity to the ground through the spindle’s mounting fixture, ensuring effective ESD protection for sensitive electronic components.

Conclusion

The PCB depaneler’s spindle is a critical driving component that significantly influences the efficiency and quality of electronic manufacturing processes. By focusing on high-speed drive technology, rigidity and precision control, and innovative ESD protection measures, manufacturers can enhance the performance and reliability of their PCB depaneling operations. As electronic components continue to evolve, so will the need for advanced spindle technologies to ensure optimal production outcomes. Emphasizing the importance of the PCB depaneler’s spindle will help in the ongoing pursuit of excellence in electronics manufacturing.

We are experienced at PCB depaneling. Know more PCB depaneling solutions in our website: www.smtglobe.com