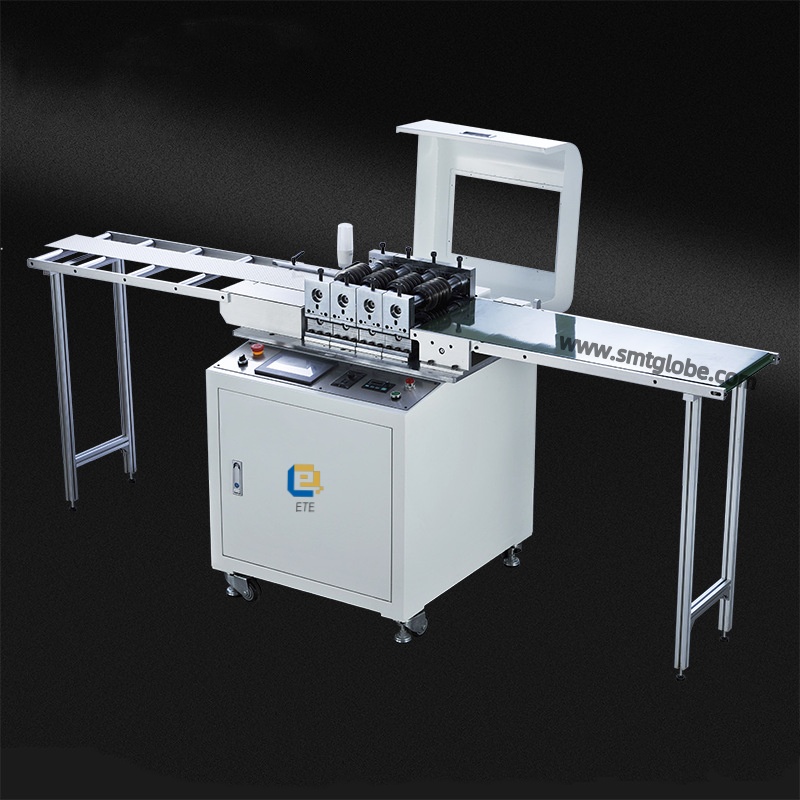

PCB Depaneler ETE-506A in high quality for Efficient and Precise Cutting. With its advanced multiple sets of blades, this high-efficiency machine offers precise cutting, increased production capacity. It also reduces labor costs. Explore the benefits of this cutting-edge solution for your LED board production needs. Also PCB separation.

Key Specifications and Features:

- Unique cutting method using six blade pieces divided into three groups (A, B, and C) to complete the PCB cutting process in three stages, reducing stress and ensuring smooth, flat edges with no twisting or warping.

- Improved stability and positioning ability of the V-CUT groove, preventing the production of defective products.

- We use a dual-frequency laser interferometer for calibration of blades to ensure perfect cutting quality.

- Adjustable “V” groove guiding device to accommodate different PCB thicknesses, increasing versatility.

- Safety features including a cutting stroke below 1-2mm.

Machine configuration:

- PCB Depaneler with built-in vacuum cleaner.

- Anti-error functions: Firstly, the conveyor belt section of the PCB Depaneler is the feeding mechanism. With no fixed edges, allowing for adjustable width. Secondary, the addition of a pressure roller adjustment plate at the conveyor belt wheel of the PCB Depaneler allows only the board edge to pass through, preventing the board from being cut incorrectly due to movement, thus improving the product yield for customers. Thirdly, adding rubber-coated wheels on both sides of the blade group of the PCB Depaneler can enhance the continuity of board feeding, allowing for continuous correction of any deviations that occur during the cutting process.

Additional Features:

- Stainless steel platforms with laser calibration positioning function available in 1.2 meters or 2.4 meters, with unlimited depaneling length.

With its advanced cutting technology, stability, and precision, our PCB depaneling machine is a top choice for high-volume LED aluminum board depaneling. Contact us to learn more about how this machine can enhance your production process.”